Ifilimu Yepulasitiki yenziwe nge-PE, PP, PVC, PS, PET, PA, kanye nezinye izinhlayiya, ezisetshenziselwa ukupakisha okuguquguqukayo noma ungqimba lwe-laminating, zisetshenziswa kabanzi ekudleni, emithini, kumakhemikhali, nakweminye imikhakha, lapho ukupakisha kokudla kubalwa khona ingxenye enkulu kakhulu. Phakathi kwazo, ifilimu ye-PE iyona esetshenziswa kakhulu, inani elikhulu kakhulu lefilimu yokupakisha yepulasitiki, ebalelwa ngaphezu kwama-40% okusetshenziswa kwefilimu yokupakisha yepulasitiki.

Ngesikhathi sokulungiselela amafilimu epulasitiki, ukuze kuthuthukiswe ukusebenza kwawo kokucubungula kanye nempilo yesevisi, ngokuvamile kuyadingeka ukwengeza ama-slip agent. Ama-slip agent anganciphisa i-friction coefficient ebusweni bamafilimu epulasitiki futhi athuthukise ukushelela kwawo, ngaleyo ndlela athuthukise ukusebenza kwawo kokucubungula futhi andise impilo yawo yesevisi.

Njengamanje, ama-slip agent avamile afaka i-amide, i-silicone ye-polymer ephezulu kakhulu, i-copolymer polysiloxane, njalo njalo. Izinhlobo ezahlukene zama-slip agent e-film zinezakhiwo ezahlukene nezinzuzo kanye nokungalungi, okulandelayo kwethula kafushane ama-slip agent amaningana avamile nokuthi ungakhetha kanjani i-slip additive ye-Plastic Film:

Ama-Amide slip agents (kufaka phakathi ama-oleic acid amides, ama-erucic acid amides, njll.):

Indima eyinhloko yezithasiselo ze-amide ekukhiqizweni kwefilimu ye-polyolefin ukunikeza izakhiwo zokushelela. Ngemva kokuba i-amide slip agent ishiye isikhunta, i-slip agent ithuthela ngokushesha ebusweni befilimu ye-polymer, futhi uma isifikile ebusweni, i-slip agent yakha ungqimba lokugcoba, olunciphisa i-coefficient of friction futhi lufeze umphumela oshelelayo.

- Izinzuzo zama-amide slip agents efilimu yepulasitiki:

Inani eliphansi lokungezelela ekulungiseleleni ifilimu (0.1-0.3%), lifakwa ngesimo sengxube noma i-masterbatch esitshalweni sokucubungula ukuqinisekisa umphumela ofanayo wokushelela; umphumela omuhle wokushelela, ungafinyelela i-coefficient ephansi yokungqubuzana, inani eliphansi kakhulu lokungezelela lingahlangabezana nezidingo.

- Izinkinga zama-amide slip agents ePlastiki Film:

Ithonya ekuphrinteni:isha ngokushesha, okuholela ekuthonyeni i-corona kanye nokunyathelisa.

Izidingo eziphezulu zokushisa kwesimo sezulu: isibonelo, inani elengeziwe ehlobo nasebusika lihlukile. Ngenxa yokushisa okuphezulu okuqhubekayo ehlobo, izinto zokugcoba ezifana ne-erucic acid amide kulula kakhulu ukuzifuduka njalo zisuka ebusweni befilimu, futhi inani elithuthelwe ebusweni befilimu lizohlanganiswa njengoba isikhathi sihamba, okuholela ekwandeni komswakama wefilimu esobala, okuthinta ukubukeka kanye nekhwalithi yezinto zokupakisha. Iphinde inamathele futhi inamathele kuma-roll ensimbi.

Ubunzima bokugcina:Ama-Amide film slip agents angathutha esuka kungqimba lokuvala ukushisa aye kungqimba lwe-corona ngemva kokuba ifilimu isilimele futhi ngesikhathi sokugcina kamuva, okuthinta kabi imisebenzi engezansi njengokuphrinta, ukubopha, kanye nokuvala ukushisa.

EKulula kakhulu ukuyifaka i-powder emhlophe:Ekupakisheni kokudla, njengoba i-slip agent ithuthela phezulu, ingase incibilike kumkhiqizo wokudla, ithinte ukunambitheka futhi ikhulise ingozi yokungcoliswa kokudla.

Ama-ejenti okushelela e-silicone anesisindo esikhulu kakhulu se-molecular wefilimu yepulasitiki:

I-polysiloxane enesisindo sama-molecule esiphezulu kakhulu ithambekele ekuthutheleni engqimbeni engaphezulu, kodwa uchungechunge lwama-molecule lude kakhulu ukuba lungagugulwa ngokuphelele, futhi ingxenye egugulwe yakha ungqimba lokugcoba oluqukethe i-silicone ebusweni, ngaleyo ndlela kufezwe umphumela wokushelela kobuso.

- Izinzuzo:

ukumelana okuhle kakhulu nokushisa okuphezulu, imvula ehamba kancane, ifaneleka kakhulu emigqeni yokupakisha ezenzakalelayo esheshayo (njengefilimu kagwayi).

- Okubi:

kulula ukuthinta ukucaca.

Nakuba lezi zithako zendabuko ze-amide Slip zivame ukusetshenziswa efilimini yepulasitiki, imboni inezinselele zayo.

Ngenxa yokwakheka kwayo, izici zesakhiwo, kanye nesisindo esincane sama-molecule, ama-Amide film slip agents endabuko athambekele kakhulu ekutholeni imvula noma ukufuthwa, okunciphisa kakhulu ukusebenza kwe-slip agent, i-coefficient of friction ayizinzile kuye ngokushisa, futhi isikulufu sidinga ukuhlanzwa njalo, futhi singadala umonakalo emishinini nasemkhiqizoni.

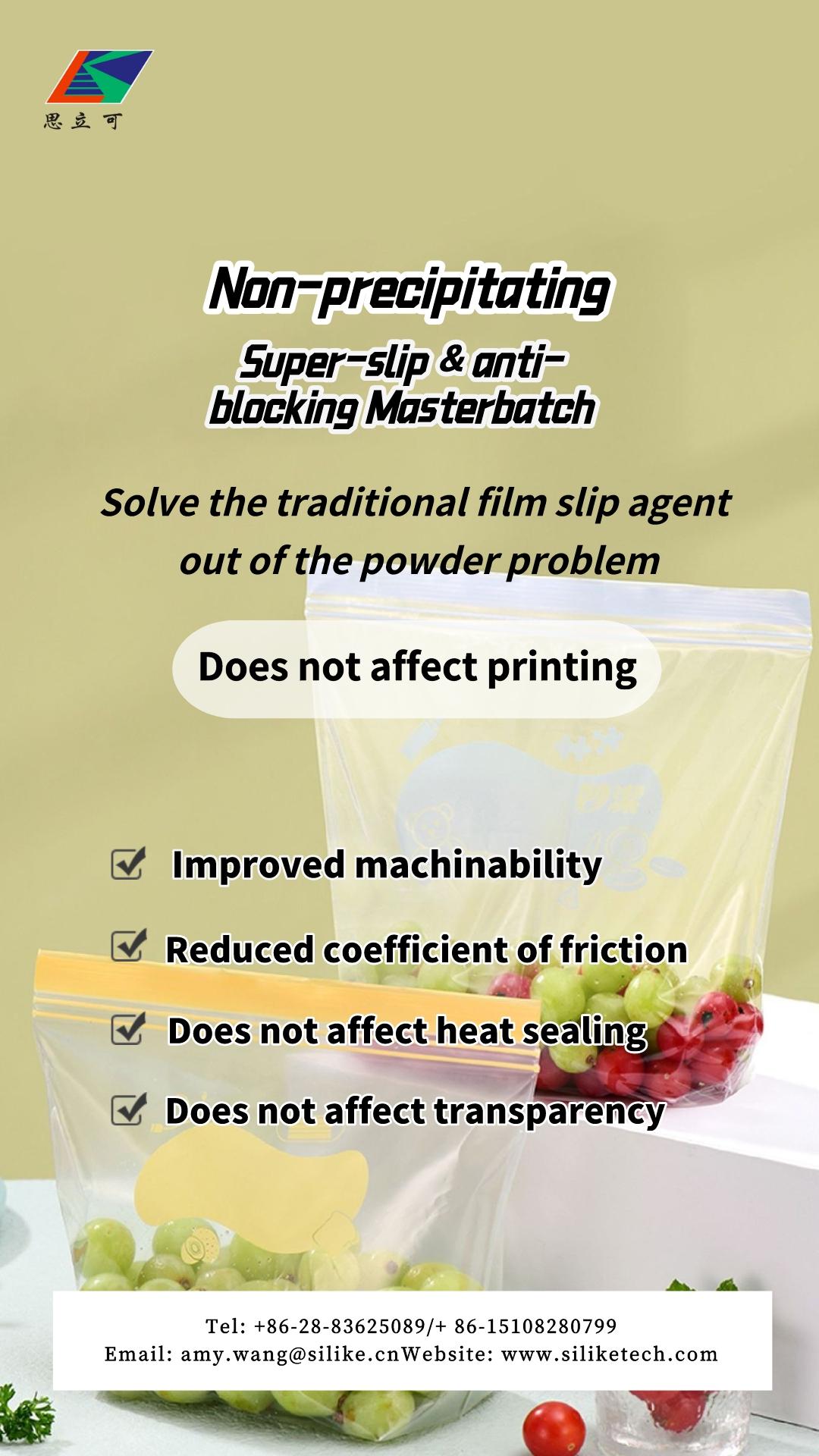

Ukubhekana Nezinselele Embonini Yamafilimu Epulasitiki:Isixazululo Esisha sika-SILIKE

Ukubhekana nezinselele eziningi ngezithasiselo zendabuko ze-Slip ezisetshenziswa ekukhiqizweni kwamafilimu epulasitiki, ikakhulukazi ngama-slip agents endabuko asekelwe kuma-amide. Ithimba le-R&D elizinikele le-SILIKE libhekane ngempumelelo nalezi zinkinga ngokuthuthukiswa kweIzithasiselo ze-Masterbatch ezingezona ezishelelayo nezivimbela ukuvimba ezishintshashintshayo- ingxenye yeUchungechunge lwe-SILIMER, okuxazulula ngempumelelo ukushiyeka kwe-ejenti yokushelela yendabuko, Engafuduki kuzo zonke izendlalelo zefilimu, iqinisekisa ukusebenza kokushelela okuzinzile nokuhlala isikhathi eside, okuletha ukusungula izinto ezintsha embonini yePlastic Film Flexible Packaging Industry. Lokhu kuphumelela kunikeza izinzuzo ezifana nethonya elincane ekuphrinteni, ekuvaleni ukushisa, ekudluliseleni, noma e-haze, kanye ne-CoF encishisiwe, ukuvimbela okuhle kokuvimba, kanye nokushelela okuthuthukisiwe kwendawo, okususa imvula emhlophe.

Uchungechunge lwe-SILIMER olungenamanzi oluyi-Super-slip kanye nochungechunge lwe-Masterbatch Additives oluvimbela ukuvinjwainezinhlelo zokusebenza eziningi ezahlukene futhi ingasetshenziswa ekukhiqizweni kwamafilimu e-BOPP/CPP/PE/TPU/EVA, njll. Afaneleka ekubunjweni, ekubunjweni nge-blow, kanye nasezinqubweni zokwelula.

KunganiIzithasiselo ze-SILIMER ze-Masterbatch ezingasheleli kakhulu futhi ezivimbela ukuvimbaingcono kunezidakamizwa ezivamile ezisekelwe kuma-amide?

Izixazululo Ezintsha Zobuchwepheshe Ezithakazelisayo Zefilimu Yepulasitiki

I-Copolymer Polysiloxane:I-SILIKE yethule i-Non-precipitating Super-slip kanye ne-anti-blocking Masterbatch Additives- ingxenye yeUchungechunge lwe-SILIMER, okuyimikhiqizo ye-polysiloxane eguquliwe equkethe amaqembu asebenzayo e-organic, ama-molecule ayo aqukethe izingxenye zochungechunge lwe-polysiloxane kanye nochungechunge olude lwe-carbon lwamaqembu asebenzayo, uchungechunge olude lwe-carbon lwamaqembu asebenzayo angahlanganiswa ngokomzimba noma ngamakhemikhali ne-base resin, angadlala indima yokubambelela, ukuze kufezwe umphumela wokufuduka okulula ngaphandle kwemvula, izingxenye zochungechunge lwe-silicone ebusweni, ngaleyo ndlela zidlale umphumela obushelelezi.

Izinzuzo zeIzithasiselo ze-SILIKE SILIMER ezingezona ezimanzi nezivimbela ukushelela ze-Masterbatch:

1. Idatha yokuhlola ikhombisa ukuthi inani elincaneI-SILIKE SILIMER 5064MB1, futhiI-SILIKE SILIMER 5065HBinganciphisa ngempumelelo i-coefficient of friction futhi ibe nokushelela okuhlala isikhathi eside nokuzinzile kungakhathaliseki isimo sezulu kanye nokushisa;

2. Ukwengezwa kweI-SILIKE SILIMER 5064MB1, futhiI-SILIKE SILIMER 5065HBngesikhathi sokulungiselela amafilimu epulasitiki akuthinti ukucaca kwefilimu futhi akuthinti inqubo yokunyathelisa elandelayo;

3. UkwengezaI-SILIKE SILIMER 5064MB1, futhiI-SILIKE SILIMER 5065HBngamanani amancane kuxazulula inkinga yokuthi ama-amide slip agents endabuko kulula ukuwalungisa noma ukuwaphusha, kuthuthukisa ikhwalithi yomkhiqizo, futhi konga izindleko eziphelele.

Ukuqina nokusebenza kahle okuphezulu kwe-Uchungechunge lwe-SILIKE SILIMER lwezithasiselo ze-Masterbatch ezingasheleli kakhulu nezivimbela ukuvimbaNgizenze zasetshenziswa emikhakheni eminingi, njengokukhiqiza amafilimu epulasitiki, amafilimu okupakisha ahlanganisiwe, izinto zokupakisha ukudla, ukukhiqizwa kwezinto zokupakisha zemithi, njll. I-SILIKE iphinde inikeze amakhasimende izixazululo zomkhiqizo ezithembeke kakhulu neziphephile, Ingabe ufuna ukufaka esikhundleni ama-ejenti okushelela e-amide ezandleni zakho? Ingabe ufuna ukufaka esikhundleni se-ejenti yakho yokushelela ye-amide yefilimu yepulasitiki, noma ufuna ukusebenzisa i-ejenti yokushelela evikela imvelo ezinzile futhi esebenza kahle yefilimu yepulasitiki, i-SILIKE iyakwamukela ukuthi uxhumane nathi nganoma yisiphi isikhathi, futhi sibheke phambili ekudaleni amathuba engeziwe kanye nawe!

Isikhathi sokuthunyelwe: Jan-10-2024