Ii-silicone masterbatch/Izinhlanganisela ze-polyethylene ephansi (LLDPE) ezihambisanayo ezinokuqukethwe okuhlukile kwe-silicone masterbatch 5%, 10%, 15%, 20%, kanye no-30%) zenziwe ngendlela yokucindezela ngokushisa futhi ukusebenza kwazo kwe-tribological kwahlolwa.

Imiphumela ikhombisa ukuthi okuqukethwe yi-silicone masterbatch kunomthelela omkhulu ekusebenzeni kokungqubuzana kwe-composite. I-friction coefficient yama-composite ingase yehle ngokwanda kokuqukethwe yi-silicone masterbatch.

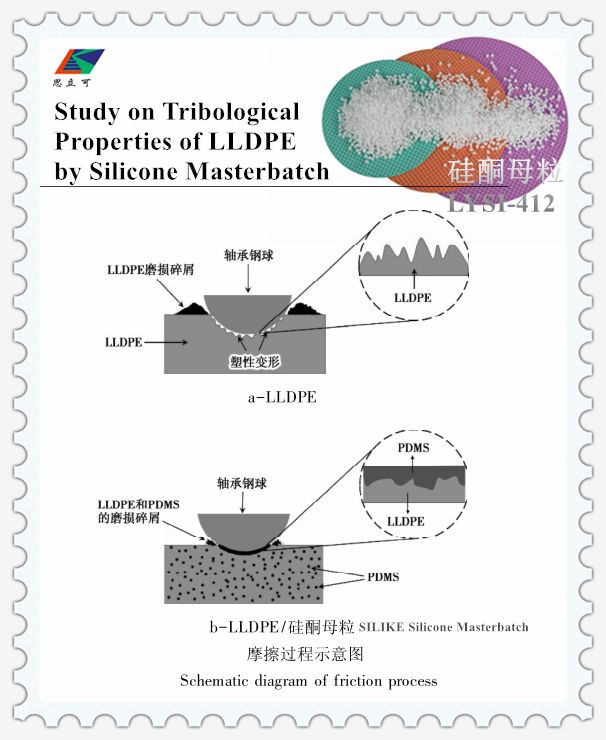

Uma okuqukethwe yi-silicone masterbatch kungu-5%, izinga lokuguguleka lingancipha ngo-90.7%, okusho ukuthi i-silicone masterbatch encane ingathuthukisa ukumelana nokuguguleka. Njengoba umthwalo osetshenziswayo ukhuphuka kusuka ku-10 N kuya ku-20 N, i-friction coefficient iyahlukahluka kusukela ku-0.33-0.54 kanye no-0.22-0.41, okubonisa ukuthi umthwalo ophezulu ungaba nomthelela ekwehleni kwe-friction coefficient ye-composite. Ukuhlaziywa kwesakhiwo sobuso bokuguguleka kukhombisa ukuthi ukuguquka kwepulasitiki kobuso obumsulwa be-LLDPE kubi kakhulu, futhi indlela eyinhloko yokuguguleka ukuguguleka okunamathelayo nokugugulekayo. Kodwa-ke, ngemva kokufakwa kwe-silicone masterbatch, ubuso bokuguguleka bezinto ezihlanganisiwe buba bushelelezi, okubangelwa kakhulu ukuguguleka okuncane.

(Lolu lwazi, lucashunwe ku-China Plastic Industry, Study on Tribological Properties of Modified by Silicone Masterbatch, College of Materials Science and Engineering, University of Liaocheng, China.)

Nokho,I-SILIKE LYSI-412I-silicone masterbatch iyifomula eyenziwe nge-pelletized equkethe i-PDMS enesisindo sama-molecule esiphezulu kakhulu esatshalaliswe ku-linear low density polyethylene (LLDPE). Yenzelwe ukusetshenziswa njengesithasiselo sokugcoba ezinhlelweni ezihambisana ne-polyethylene ukuze inikeze izinzuzo ezifana nezakhiwo ezithuthukisiwe zomphezulu (ukuthambisa, ukushelela, i-coefficient ephansi yokungqubuzana, umuzwa we-silky).

Isikhathi sokuthunyelwe: Juni-30-2021