Enkathini lapho izindinganiso zokuphepha kanye nemithethonqubo kubaluleke kakhulu, ukuthuthukiswa kwezinto ezimelana nokusabalala komlilo sekuyinto ebalulekile emikhakheni eyahlukahlukene. Phakathi kwalezi zinto ezintsha, ama-masterbatch compounds agcina umlilo avele njengesixazululo esiyinkimbinkimbi sokuthuthukisa ukumelana nomlilo kwama-polymers.

Ukuqonda ukuthi ayini ama-Masterbatch Compounds avimbela ilangabi?

Ama-masterbatch compounds avimbela umlilo ayizindlela ezikhethekile ezenzelwe ukunikeza izakhiwo ezingashi kuma-polymers. Lawa ma-compounds aqukethe i-carrier resin, evame ukuba yi-polymer efanayo nezinto eziyisisekelo, kanye nezithasiselo ezivimbela umlilo. I-carrier resin isebenza njengendawo yokusabalalisa ama-agent avimbela umlilo kuyo yonke i-polymer matrix.

Izingxenye ze-Flame Retardant Masterbatch Compounds:

1. I-Carrier Resin:

I-carrier resin yakha ingxenye enkulu ye-masterbatch futhi ikhethwa ngokusekelwe ekuvumelaneni ne-base polymer. Ama-carrier resin avamile afaka i-polyethylene (PE), i-polypropylene (PP), i-polyvinyl chloride (PVC), kanye nezinye i-thermoplastics. Ukukhetha i-carrier resin kubalulekile ukuqinisekisa ukusabalala okuphumelelayo kanye nokuhambisana ne-polymer eqondiwe.

2. Izithasiselo Ezivimbela Umlilo:

Izithako ezivimbela amalangabi ziyizithako ezisebenzayo ezibangela ukuvimbela noma ukubambezela ukusabalala kwamalangabi. Ngokuyisisekelo, izithako ezivimbela amalangabi zingaba yizinto ezisabelayo noma ezingeziwe. Lezi zithako zingahlukaniswa ngezigaba ezahlukene, kufaka phakathi ama-halogenated compounds, ama-compounds asekelwe ku-phosphorus, kanye nama-mineral fillers. Isigaba ngasinye sinohlelo lwaso oluhlukile lokusebenza ekucindezeleni inqubo yokusha.

2.1 Ama-Halogenated Compounds: Ama-Brominated nama-chlorine compounds akhipha ama-halogen radicals ngesikhathi sokusha, okuphazamisa ukusabela kwe-combustion chain.

2.2 Ama-Compounds Asekelwe ku-Phosphorus: Lawa ma-compounds akhipha i-phosphoric acid noma i-polyphosphoric acid ngesikhathi sokusha, akha ungqimba oluvikelayo olucindezela ilangabi.

2.3 Izithasiselo Zamaminerali: Izithasiselo ezingaphili njenge-aluminium hydroxide kanye ne-magnesium hydroxide zikhipha umhwamuko wamanzi uma zivezwa ekushiseni, zipholise izinto futhi zinciphise amagesi avuthayo.

3. Izinto Zokugcwalisa Nokuqinisa:

Ama-filler, njenge-talc noma i-calcium carbonate, avame ukungezwa ukuthuthukisa izakhiwo ze-masterbatch compound. Ama-reinforcements athuthukisa ukuqina, amandla, kanye nokuqina kobukhulu, okufaka isandla ekusebenzeni okuphelele kwezinto.

4. Iziqinisi:

Ama-stabilizer afakwa ukuvimbela ukuwohloka kwe-polymer matrix ngesikhathi sokucubungula nokusetshenziswa. Ama-antioxidants kanye nama-UV stabilizer, isibonelo, asiza ukugcina ubuqotho bento lapho ivezwa ezicini zemvelo.

5. Izinto zokufaka imibala kanye nemibala:

Kuye ngokusetshenziswa, izinto zokufaka imibala kanye nemibala ziyangezwa ukuze kufakwe imibala ethile ku-masterbatch compound. Lezi zingxenye zingathinta futhi izakhiwo zobuhle bezinto ezibonakalayo.

6. Izinto ezihambisanayo:

Ezimweni lapho i-flame retardant kanye ne-polymer matrix zibonisa ukuhambisana okungekuhle, kusetshenziswa ama-compatibilizer. Lawa ma-ejenti athuthukisa ukusebenzisana phakathi kwezingxenye, akhuthaza ukuhlakazeka okungcono kanye nokusebenza okuphelele.

7. Izinto Zokucindezela Intuthu:

Izinto ezicindezela intuthu, njenge-zinc borate noma i-molybdenum compounds, ngezinye izikhathi ziyafakwa ukuze kuncishiswe ukukhiqizwa kwentuthu ngesikhathi sokusha, okuyinto ebalulekile ekucatshangelweni kokuphepha komlilo.

8. Izithasiselo Zokucubungula:

Izinsiza zokucubungula ezifana nokugcoba kanyeama-ejenti okuhlakazayenza inqubo yokukhiqiza ibe lula. Lezi zithasiselo ziqinisekisa ukucutshungulwa okubushelelezi, zivimbele ukuhlangana, futhi zisize ekufezeni ukusabalala okufanayo kwezithibi zomlilo.

Lokhu okungenhla konke kuyizingxenye zamakhemikhali e-masterbatch avimbela umlilo, kuyilapho Ukuqinisekisa ukusatshalaliswa ngokulinganayo kwe-flame retardant ngaphakathi kwe-polymer matrix kuyisici esibalulekile sokusebenza kwazo. Ukuhlakazeka okunganele kungaholela ekuvikelweni okungalingani, izakhiwo zezinto ezisengozini, kanye nokuphepha komlilo okuncishisiwe.

Ngakho-ke, ama-flame retardant masterbatch compounds avame ukudingaabasabalalisiukubhekana nezinselele ezihambisana nokusabalala okufanayo kwezinto ezivimbela ilangabi ngaphakathi kwe-polymer matrix.

Ikakhulukazi Emkhakheni oguqukayo wesayensi ye-polymer, isidingo sezinto ezi-Flame Retardant ezithuthukisiwe ezinezakhiwo zokusebenza okuphezulu sikhuthaze ukusungulwa kwezinto ezintsha ezithasiselweni nasezilungisini. Phakathi kwezixazululo eziqalayo,ama-hyperdispersantsbavele njengabadlali ababalulekile, bebhekana nezinselele zokufinyelela ukusabalala okuhle kakhulu ku-Flame Retardant Masterbatch compound formulations.

As ama-hyperdispersantsbhekana nale nselele ngokukhuthaza ukusatshalaliswa okuphelele nokulinganayo kwezinto ezivimbela umlilo kulo lonke i-masterbatch compound.

Faka i-Hyperdispersant SILIKE SILIMER 6150—uhlobo lwezithasiselo ezishintsha isimo sezinto ezivimbela ilangabi!

I-SILIKE SILIMER 6150, yathuthukiswa ukuze ihlangabezane nezidingo ezihlukile zomkhakha we-polymer, iyi-silicone wax eguquliwe. Njenge-i-hyperdispersant esebenza kahle, inikeza ikhambi lezinselele ezihambisana nokufinyelela ukuhlakazeka okuhle kakhulu, ngenxa yalokho, ukuphepha komlilo okuhle kakhulu.

Kunconywa i-SILIKE SILIMER 6150ukusabalala kwezinhlayiya zezinto eziphilayo nezingaphili kanye nezigcwalisi, izinto ezivimbela ilangabi ku-thermoplastic masterbatch, TPE, TPU, ezinye i-thermoplastic elastomers, kanye nezinhlelo zokusebenza ezihlanganisiwe. Ingasetshenziswa kuma-polymer ahlukahlukene e-thermoplastic kufaka phakathi i-polyethylene, i-polypropylene, i-polystyrene, i-ABS, kanye ne-PVC.

I-SILIKE SILIMER 6150, Inzuzo ebalulekile yamakhemikhali agcina ilangabi

1. Thuthukisa ukuhlakazeka okubambezela ilangabi

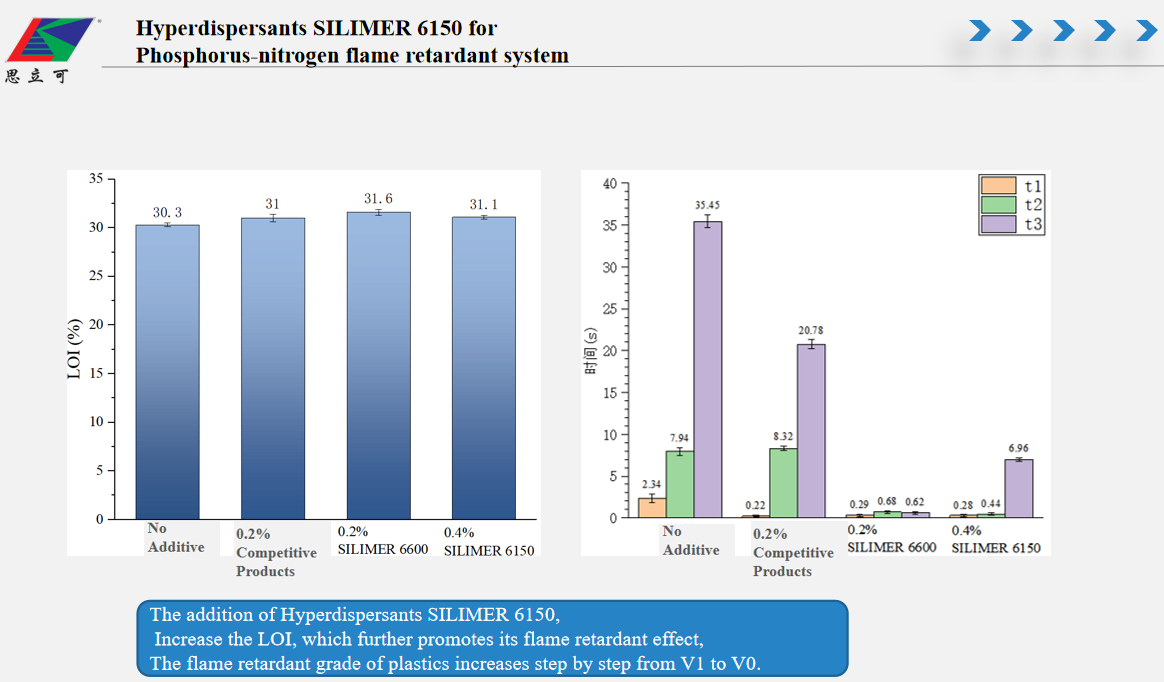

1) I-SILIKE SILIMER 6150 ingasetshenziswa kanye ne-masterbatch ye-phosphorus-nitrogen evimbela ilangabi, okuthuthukisa ngempumelelo umphumela wokuvimbela ilangabi we-flame retardant. Ukwandisa i-LOI, izinga lepulasitiki elivimbela ilangabi landa isinyathelo ngesinyathelo kusukela ku-V1 kuya ku-V0.

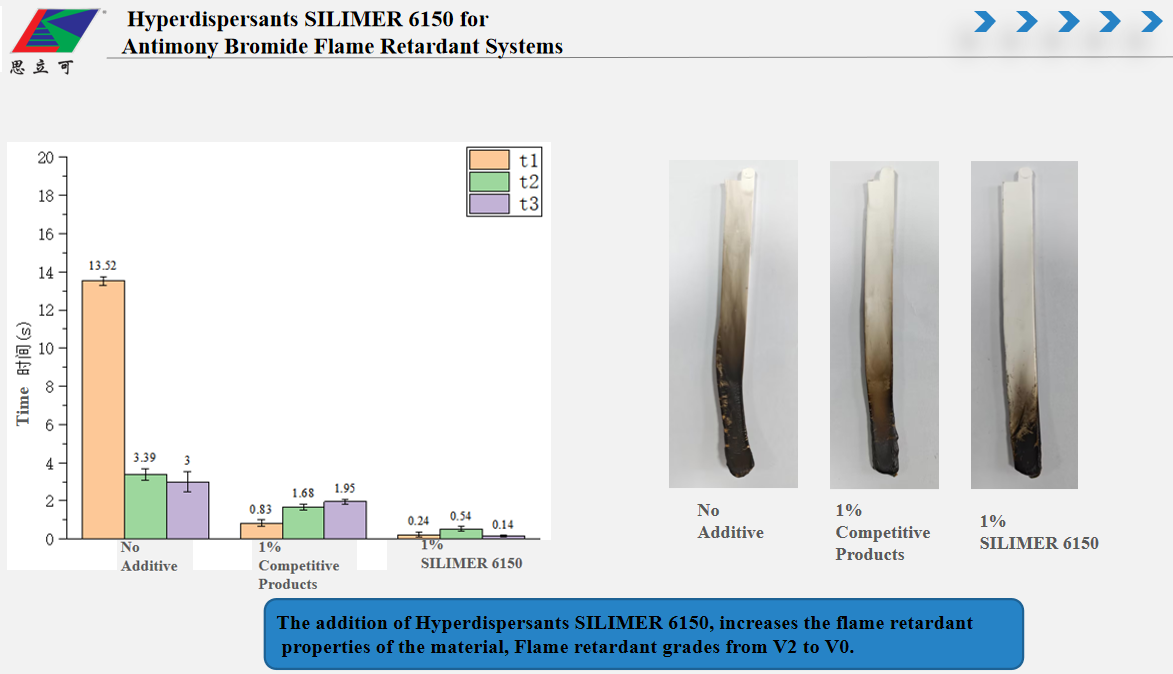

2) I-SILIKE SILIMER 6150 futhi inokuxhumana okuhle kokuvimbela ilangabi ne-Antimony Bromide Flame Retardant Systems, amazinga okuvimbela ilangabi kusukela ku-V2 kuya ku-V0.

2. Thuthukisa ukucwebezela kanye nokushelela kobuso bemikhiqizo (i-COF ephansi)

3. Amazinga okugeleza okuncibilika athuthukisiwe kanye nokusabalala kwama-filler, ukukhishwa kwesikhunta okungcono kanye nokusebenza kahle kokucubungula

4. Amandla ombala athuthukisiwe, akukho mphumela omubi ezimpahleni zemishini.

Xhumana ne-SILIKE ukuze ubone ukuthi i-SILIMER 6150 Hyperdispersant ingasiza kanjani abakhiqizi ekwenzeni ama-compounds amasha avimbela ilangabi kanye ne-thermoplastics!

Isikhathi sokuthunyelwe: Okthoba-23-2023