Izithasiselo Zokucubungula i-Polymer (PPA) yigama elijwayelekile lezinhlobo eziningana zezinto ezisetshenziswa ukuthuthukisa izakhiwo zokucubungula nokuphatha ama-polymer, ikakhulukazi esimweni esincibilikisiwe se-polymer matrix ukuze zidlale indima. Ama-fluoropolymer kanye nezinsiza zokucubungula i-polymer ze-silicone resin zisetshenziswa kakhulu kuma-polymer e-polyolefin.

I-PPA ingasetshenziswa ezintweni ezifaka phakathi i-LLDPE, i-LDPE, i-HDPE, i-MDPE, i-PP, ama-elastomer e-thermoplastic, i-PS, i-nylon, ama-resin e-acrylic, i-PVC njalo njalo. Izinkambu zokusetshenziswa zingaba ifilimu evuvukile, i-cast extrusion, ucingo nekhebula, i-pipe and sheet extrusion, i-masterbatch processing, i-hollow blow molding, njalo njalo.

Indima eyinhloko ye-Polymer Processing Aid (PPA) ekukhiqizweni nasekucutshungulweni kwezintambo nezintambo ukuthuthukisa ukusebenza kokucubungula i-polymer kanye nekhwalithi yomkhiqizo. Nazi ezinye zezizathu eziyinhloko zokwengeza i-PPA:

1. Ukuncipha Kokuncibilika Okuncibilikile: I-PPA inganciphisa ukuncibilika kwama-polymer, okwenza kube lula ukugeleza ngesikhathi sokucubungula futhi kuthuthukiswe isivinini sokukhipha kanye nokukhiqiza.

2. Ukubukeka Komkhiqizo Okuthuthukisiwe: I-PPA ingathuthukisa ukucwebezela kobuso kanye nokuba yisicaba kwemikhiqizo yezintambo kanye nekhebula, inciphise amaphutha okubukeka kanye nokungapheleli, futhi ithuthukise ubuhle bomkhiqizo kanye nenani.

3. Nciphisa ukusetshenziswa kwamandla: Njengoba i-PPA yehlisa ukuncibilika kwe-polymer, amazinga okushisa aphansi okucubungula, kanye nokucindezela kuyadingeka ngesikhathi sokukhipha, ngaleyo ndlela kunciphisa ukusetshenziswa kwamandla kanye nezindleko.

4. Ukuqina okuthuthukisiwe kwe-extrusion: Ukwengezwa kwe-PPA kuthuthukisa ukugeleza kanye nokuqina kokuncibilika kwe-polymer, kunciphisa ukukhishwa okushintshanayo kanye nokuwohloka ngesikhathi sokukhishwa, okuholela kumkhiqizo ozinzile kakhulu ngobukhulu kanye nekhwalithi.

Ngokuvamile, ukwengezwa kokucubungula i-polymer kusiza i-PPA ukuthuthukisa ukusebenza kokukhiqizwa nokucubungula kwentambo nekhebula, futhi kuthuthukise ikhwalithi yomkhiqizo kanye nokusebenza kahle. Kodwa ngokuvinjelwa okuhlongozwayo kwe-fluoride, ukuthola ezinye izindlela esikhundleni se-PPA ene-fluorine sekuyinselele entsha.

Ukuze kuxazululwe le nkinga, i-SILIKE yethule uhleloEnye indlela engenayo i-PTFEku-PPA esekelwe ku-Fluorine ——isithasiselo sokucubungula i-polymer esingenayo i-PFAS (i-PPAS)LokhuI-PPA MB engena-fluorine, Isithasiselo esingenayo i-PTFEiyi-polysiloxane masterbatch eguquliwe ngokwemvelo esebenzisa umphumela omuhle kakhulu wokuthambisa wokuqala wama-polysiloxane kanye ne-polarity yamaqembu aguquliwe ukuze athuthe futhi asebenze emishinini yokucubungula ngesikhathi sokucubungula.

Izinsiza zokucubungula i-polymer ezingenayo i-PFAS (i-PPA)——kusiza ukukhiqizwa kwezintambo nezintambo ukuthi kusebenze kahle kakhulu >>

I-SILIKE ithuthukisa i-PPA engena-fluorine njengokufaka esikhundleni esifanele sezinsiza zokucubungula i-PPA ene-fluorine, okungeziwe okuncane kwe-Isithasiselo sokucubungula i-SILIKE SILIMER-5090 esingeyona i-fluoropolymerkuthuthukisa ukusebenza kokucubungula ucingo kanye nekhebula. Kunciphisa ngempumelelo ukucindezela kwekhanda le-die, kuthuthukisa ukuzinza kwe-extrusion, kunciphisa ukushaya kwe-extrusion, kuqeda ukwakheka kwekhanda le-die, kuthuthukisa kakhulu ukugeleza kokucubungula, kunciphisa i-torque futhi kuthuthukisa umkhiqizo. Kuthuthukisa ikhwalithi yobuso kanye nokushelela kwemikhiqizo.

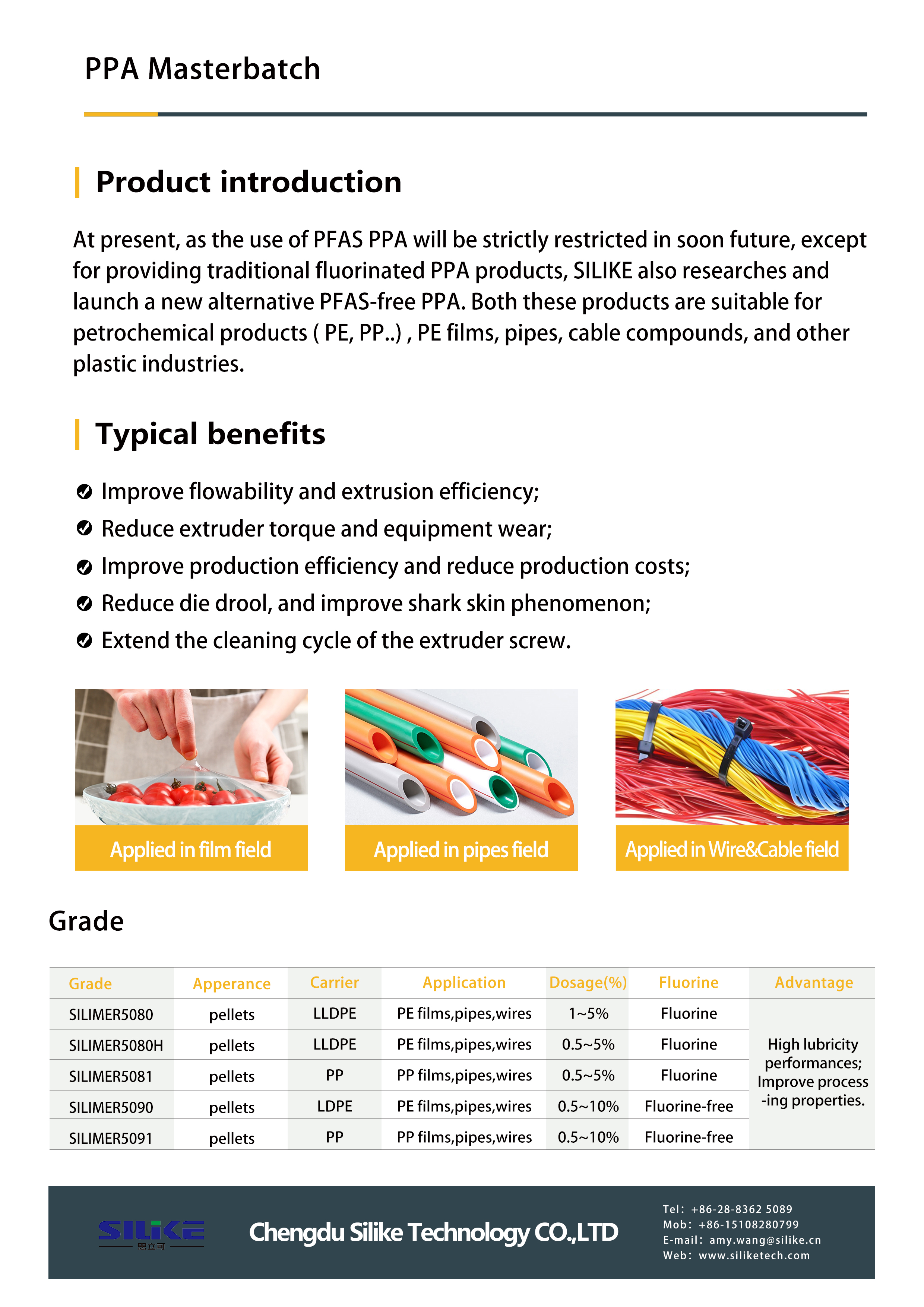

Izinsiza zokucubungula i-polymer ezingenayo i-SILIKE PFAS (PPAS) (PPA)inezinhlobo eziningi zezicelo zezintambo, amafilimu, amashubhu, ama-masterbatches, utshani bokwenziwa, njll.

Ukusebenza okuvamile:

Ukucutshungulwa okuthuthukisiwe

Ukugcotshwa nokuhlakazeka okusebenzayo

Ukusebenza kahle kokucubungula okuthuthukisiwe

Kuqeda ukuqhekeka kokuncibilika

Kunciphisa ukuvuza kwamanzi kanye nokwakheka kwama-die

Ngezansi kunamazinga anconyiwe e-Izinsiza zokucubungula i-SILIKE PPA, ungazibuka. Uma unemibuzo, sicela ungangabazi ukungithinta. I-SILIKE ilangazelela ukukunikezaizixazululo ze-PPA engena-fluorine kuzinhlelo zokusebenza zezintambo nezekhebula.

Isikhathi sokuthunyelwe: Novemba-10-2023