I-black masterbatch iyisici esibalulekile emikhakheni eminingi, kufaka phakathi imicu yokwenziwa (njengamakhaphethi, i-polyester, kanye nezindwangu ezingalukiwe), imikhiqizo yefilimu epheshuliwe (njengezikhwama zokupakisha namafilimu aqoshiwe), imikhiqizo ebunjiwe (njengezitsha zemithi nezimonyo), imikhiqizo ekhishwe (kufaka phakathi amashidi, amapayipi, kanye nezintambo), kanye nemikhiqizo ebunjiwe ngomjovo (njengezingxenye zezimoto kanye nezinto zikagesi). Izinzuzo zayo—ukusebenziseka kalula, ukungabi nokungcola, umbala ohambisanayo, ikhwalithi yezingxenye zepulasitiki ethuthukisiwe, kanye nokuhambisana nezinhlelo zokukhiqiza ezenzakalelayo—kwenza kube yinto ebalulekile. Ngaphezu kwalokho, i-black masterbatch ingahlanganisa izithasiselo ezahlukahlukene, ithuthukise ukusebenza kwayo kanye nokulula kwayo.

Imibuzo Evamile Nezici Eziyinhloko Zama-Black Masterbatches

Izingxenye ezibalulekile ze-black masterbatch zifaka phakathi i-carbon black, i-carbon black carrier, i-carbon black wetting agent, i-carbon black dispersant, nezinye izinsiza zokucubungula. Abakhiqizi bavame ukubhekana nezinselele ezinkulu ekukhiqizweni kwe-black masterbatch. Izinkinga ezifana nokuhlushwa okuphansi kombala, ukungcola ngesikhathi sokudaya, ukusabalala okubi kwe-carbon black, kanye nokungabi mnyama ngokwanele kanye nokukhanya kungathinta ikhwalithi yomkhiqizo wokugcina. Lezi zinkinga ziholela ekungahambelani kombala, ukwehla kwezakhiwo zezinto, kanye nobunzima bokucubungula.

Ucwaningo Lwesibonelo: Ukubhekana Nezinkinga Zokuhlakazeka Ekukhiqizweni Kwe-Black Masterbatch

Abanye abakhiqizi be-blackbatch babhekene nenkinga enkulu. Ukwakheka kwabo, okuqukethe u-40% we-carbon black kanye nokusebenzisa i-EVA wax njengesihlanzi, kubonise izakhiwo zomzimba ezingaguquki ngesikhathi sokukhipha. Ezinye izintambo ezikhishwe zazibuthakathaka, kanti ezinye zaziqinile ngendlela engavamile, naphezu kokusebenzisa i-twin-screw extruder kanye nokugcina amazinga okushisa alawulwayo aphakathi kuka-160°C no-180°C. Yini eyabangela inkinga? Lokhu kungahambisani kukhomba inkinga evamile ekukhiqizweni kwe-black masterbatch: ukusabalala okungafani kwe-carbon black.

Iyiphi Indlela Engcono Kakhulu Yokuxazulula Ukusabalala Okumnyama Kwe-Pigment? Ukuqonda Ukusabalala Okumnyama Kwe-Carbon

I-carbon black, i-powder ecolekile esetshenziselwa ukuqinisa umbala nokuqinisa, ibeka inselele yokusabalala ngenxa yendawo yayo ephezulu kanye nokuthambekela kokuhlangana. Ukufinyelela ukusabalala okufanayo ngaphakathi kwe-polymer matrix kubalulekile ekugcineni ikhwalithi yomkhiqizo. Ukusabalala okungafani kungaholela emigqeni, amabala, imibala engalingani, kanye nokungahambisani kwezakhiwo zomzimba (njengokuphuka noma ukuqina okungavamile).

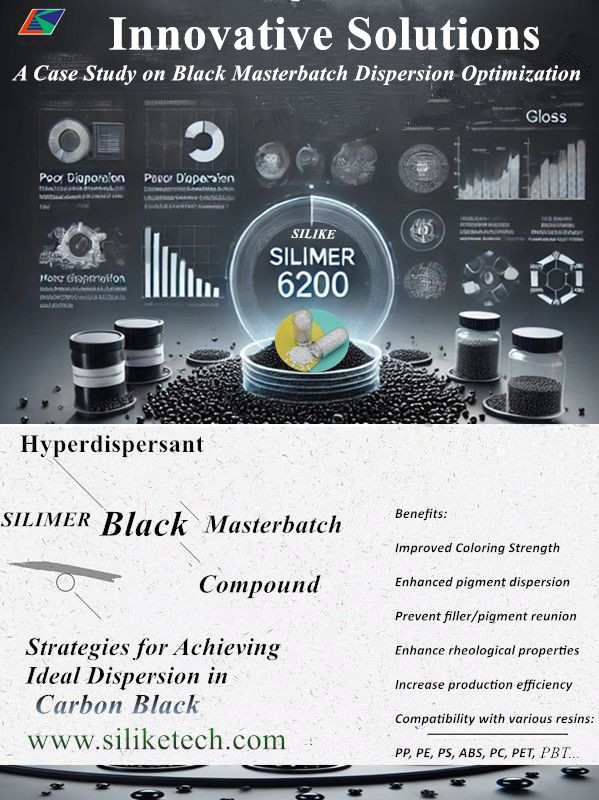

OkushaIzixazululo Zokufeza Ukusabalala Okufanayo Ekukhiqizweni Kwe-Black Masterbatch:Sethula I-SILIKE's SILIMER 6200:I-Hyperdispersant Eqinisekisiwe

I-Hyperdispersant SILIMER 6200iklanyelwe ngqo ukubhekana nezinselele zokusabalala kombala omnyama nomnyama wekhabhoni, ukuthuthukisa ukufana nokuthuthukisa ikhwalithi iyonke yomkhiqizo wokugcina.

Izinzuzo:

- Ukusabalala Kwemibala Okuthuthukisiwe: I-Hyperdispersant SILIMER 6200kuthuthukisa ukusabalala komnyama wekhabhoni, okuqinisekisa ukuthi umbala uhlala ufana.

- Amandla Okufaka Umbala Athuthukisiwe: I-Hyperdispersant SILIMER 6200kwandisa ukusebenza kahle kwe-carbon black ekufezeni izithunzi ezifiselekayo.

- Ukuvimbela Ukuhlanganiswa Kokugcwalisa Nokuhlanzwa Kwemibala: I-Hyperdispersant SILIMER 6200kusiza ukugcina ukufana ngokuvimbela ukuhlangana kwezinhlayiya.

- Izakhiwo Ezingcono Ze-Rheological: I-Hyperdispersant SILIMER 6200kuthuthukisa izici zokugeleza kwe-masterbatch, okwenza kube lula ukucubungula.

- Ukwanda Kokusebenza Kahle Kokukhiqiza, Ukunciphisa Izindleko: I-Hyperdispersant SILIMER 6200kunegalelo enqubweni yokukhiqiza esebenza kahle kakhulu.

I-Hyperdispersant SILIMER 6200iyahambisana nezinhlobonhlobo zama-resin, kufaka phakathi i-PP, i-PE, i-PS, i-ABS, i-PC, i-PET, i-PBT, nokuningi, okwenza kube ukukhetha okuhle kakhulu kwezinhlobo eziningi zezicelo kuma-masterbatches nama-compounds.

Don’t let dispersion issues compromise your black masterbatch product quality. Email us at amy.wang@silike.cn to learn more about how I-Hyperdispersant ye-SILIKE i-SILIMER 6200ingakusiza ukuthi uthole imiphumela ehambisanayo futhi uhlangabezane nezidingo ezahlukahlukene ze-masterbatches yakho kanye nomkhakha we-compounds.

Isikhathi sokuthunyelwe: Novemba-19-2024