Ukukhiqizwa kwepulasitiki kuyimboni ebalulekile ebalulekile emphakathini wanamuhla ngoba inikeza imikhiqizo eyahlukahlukene esetshenziswa ekuphileni kwansuku zonke. Ipulasitiki isetshenziselwa ukwenza izinto ezifana nokupakisha, izitsha, imishini yezokwelapha, amathoyizi, kanye nezinto zikagesi. Iphinde isetshenziswe ezimbonini zokwakha, zezimoto kanye nezindiza. Ipulasitiki ilula, ihlala isikhathi eside, futhi iyabiza, okwenza ibe yinto efanelekile yezinhlelo zokusebenza eziningi. Ngaphezu kwalokho, enye ipulasitiki ingaphinde isetshenziswe, okwenza kube ukukhetha okunobungani nemvelo.

Kubakhiqizi bepulasitiki, bavame ukuzibophezela ekusebenzeni kahle kokucubungula kanye nendlela yokufeza ukuqeda okubushelelezi ezingxenyeni zepulasitiki. ngoba bangasiza ekunciphiseni izindleko zokukhiqiza, bathuthukise ikhwalithi yomkhiqizo, futhi bandise isikhathi eside sezingxenye. Ngaphezu kwalokho, ukuqeda okubushelelezi kungasiza ekunciphiseni ukungqubuzana nokuguguleka, okungasiza ekuthuthukiseni ukusebenza kwezingxenye. Okokugcina, ukuqeda okubushelelezi kungasiza futhi ekuthuthukiseni ukubukeka kwezingxenye, okwenza zikhange kakhulu kumakhasimende.

Ungakuthuthukisa kanjani ukusebenza kahle kokukhiqiza ipulasitiki kanye nekhwalithi yobuso?

Ngokuvamile, kunezindlela eziningana zokuthuthukisa ukucutshungulwa kwepulasitiki kanye nekhwalithi yendawo. Lokhu kufaka phakathi: ukusebenzisa i-PE, i-PP, i-PVC, i-PBT, i-PET, i-ABS, i-PC esezingeni eliphezulu, kanye nezinye izinto zokusetshenziswa ze-thermoplastic, ukwenza ngcono inqubo yokubumba ngomjovo, ukusebenzisa amasu okupholisa angcono, kanye nokusebenzisa amasu okucubungula ngemuva kokucubungula njengokupholisa nokufaka i-buffing. Ngaphezu kwalokho, ukusebenzisa izithasiselo ezifana nezithasiselo zokucubungula, amafutha okugcoba, kanye nama-release agents kungasiza ekuthuthukiseni izakhiwo zokucubungula, ukukhiqiza, kanye nokuphela kwendawo yezingxenye zepulasitiki.

I-Silicone ingenye yezithasiselo zepulasitiki ezidumile kakhulu ezisetshenziselwa ukuthuthukisa ukusebenza kokucubungula ngenkathi kulungiswa izakhiwo zobuso, njengokuthuthukisa ubuso obubushelelezi, ukunciphisa i-coefficient yokungqubuzana, ukumelana nokuklwebheka, ukumelana nokuklwebheka, kanye nokugcotshwa kwama-polymer. Lesi sithasiselo sisetshenziswe ezinhlotsheni zoketshezi, ze-pellet, kanye ne-powder, kuye ngesidingo seprosesa yepulasitiki.

Ngaphezu kwalokho, kufakazelwe ukuthi abakhiqizi bazo zonke izinhlobo ze-thermoplastics kanye nepulasitiki yobunjiniyela bafuna ukuthuthukisa amazinga okukhipha, bafinyelele ukugcwaliswa kwesikhunta okuqhubekayo, ukukhululwa kwesikhunta, ikhwalithi ephezulu kakhulu, ukusetshenziswa kwamandla okuphansi, kanye nokusiza ukunciphisa izindleko zamandla, konke ngaphandle kokwenza izinguquko emishinini yokucubungula evamile. Bangazuza ezithasiselweni ze-silicone, futhi basize imizamo yabo yomkhiqizo eya emnothweni ojikelezayo.

I-Chengdu Silike Technology Co., Ltd ingumsunguli we-silicone emkhakheni wezinhlelo zokusebenza zerabha nepulasitiki eShayina, ihole ekucwaningeni i-SILICONE ne-PLASTIC (izinhlanganisela ezimbili ezihambisanayo zokuxubana), igxile ku-R&D yezithasiselo ze-silicone iminyaka engaphezu kwengu-20. futhi ithuthukise imikhiqizo ehlukene ye-silicone.i-silicone masterbatch, impuphu ye-silicone, i-masterbatch yokulwa nokuklwebheka, ai-masterbatch yokulwa nokuguguleka, igrisi ye-WPC,i-masterbatch ethambile kakhulu, I-wax ye-silicone ye-SILIMER, i-masterbatch elwa nokuklewula,i-silicone flame retardant synergist, i-PPA, i-silicone molding,i-silicone gum,ezinye izinto ezisekelwe ku-silicone,I-Si-TPVfuthi nokuningi…

Lezi zithasiselo ze-silicone zisiza ekuthuthukiseni izakhiwo zokucubungula zezinto zepulasitiki kanye nekhwalithi ephezulu yezingxenye eziqediwe ze-telecom ducts, ingaphakathi lezimoto, izintambo zekhebula nezintambo, amapayipi epulasitiki, izithende zezicathulo, ifilimu, indwangu, izinto zikagesi zasekhaya, izinhlanganisela zepulasitiki zokhuni, izingxenye ze-elekthronikhi, kanye neminye imboni.

Izithasiselo ze-silicone ze-Silike zinikeza Izindlela zokuthuthukisa ukucutshungulwa kwepulasitiki kanye nekhwalithi yobuso, ezifinyelela isiphetho esiphelele ezingxenyeni zepulasitiki. Umkhiqizo wezithasiselo ze-silicone ze-SILIKE usetshenziswa kabanzi ekubumbeni ngomjovo, ekubumbeni kwe-extrusion, kanye nasekubumbeni nge-blow.

Ngaphezu kwalokho, ukuthola i-silicone efanele yohlelo lwakho lokusebenza akukhawulelwe kuphothifoliyo yomkhiqizo we-SILIKE. Ithimba lethu lobuchwepheshe lizosebenzisana nawe ukushintsha imininingwane kumkhiqizo wamanje noma ukwenza okusha ngokwezifiso ukuze kuhlangatshezwane nezidingo zakho eziqondile. Okubalulekile ukuthi singakwazi futhi ukwenza ngokwezifiso umkhiqizo omusha ngokwezicelo zemininingwane yesicelo samakhasimende, i-resin ehambisanayo, kanye nokuqukethwe kwe-silicone enesisindo sama-molecule ngokufanele, ngenxa yokuthi ubuchwepheshe bethu obuyinhloko buwukulawula isakhiwo se-PDMS…

Kuyini i-silicone?

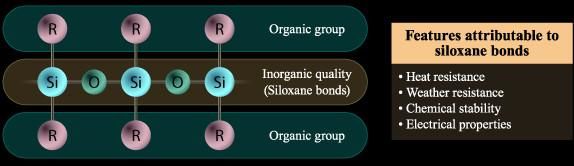

I-Silicone iyinhlanganisela yokwenziwa engangenisi lutho, Isakhiwo esiyisisekelo se-silicone sakhiwe ngama-polyorganosiloxanes, lapho ama-athomu e-silicon exhunyaniswa nomoya-mpilo ukuze kudalwe isibopho se-"siloxane". Ama-valence asele e-silicon ahlobene namaqembu e-organic, ikakhulukazi amaqembu e-methyl (CH3): i-Phenyl, i-vinyl, noma i-hydrogen.

Isibopho se-Si-O sinezici zamandla amakhulu ethambo, kanye nezakhiwo zamakhemikhali ezizinzile kanye nethambo le-Si-CH3 lijikeleza ithambo le-Si-O ngokukhululeka, ngakho-ke ngokuvamile i-silicone inezakhiwo ezinhle zokuvimbela ukushisa, ukumelana nokushisa okuphansi nokuphezulu, izakhiwo zamakhemikhali ezizinzile, ukungabi namandla okuhle komzimba, kanye namandla aphansi omhlaba. Ngakho-ke zisetshenziswa kabanzi ekucutshungulweni okuthuthukisiwe kwepulasitiki kanye nekhwalithi yobuso bezingxenye eziqediwe zezingxenye zangaphakathi zezimoto, izintambo kanye nezintambo, amapayipi okuxhumana, izicathulo, ifilimu, ukumboza, indwangu, izinto zikagesi, ukwenza amaphepha, ukupenda, ukuhlinzekwa kokunakekelwa komuntu siqu, kanye neminye imboni. Ihlonishwa njenge-"industrial monosodium glutamate".

Isikhathi sokuthunyelwe: Meyi-11-2023