I-polyamide resin, efushaniswe ngokuthi i-PA, yaziwa kakhulu ngokuthi i-nylon. Iyiyunithi ephindaphindayo yeketanga elikhulu lama-macromolecule equkethe amaqembu e-amide ku-polymer yegama elijwayelekile. Amapulasitiki amahlanu obunjiniyela ekukhiqizweni okukhulu, izinhlobo eziningi kakhulu, izinhlobo ezisetshenziswa kakhulu, kanye nezinye izingxube ze-polymer nama-alloy, njll., ahlangabezana nezidingo ezikhethekile ezahlukene, asetshenziswa kabanzi esikhundleni sensimbi, ukhuni, nezinye izinto zendabuko.

I-PA6 iyinto eyenziwe nge-nylon, enamandla ayo okusebenza aphezulu kodwa aphansi kune-PA66; amandla okunamathela, ubulukhuni bomphezulu, kanye nokuqina kuphakeme kunezinye ipulasitiki ze-nylon, kanye nokumelana nokuguquguquka komthelela kune-PA66.

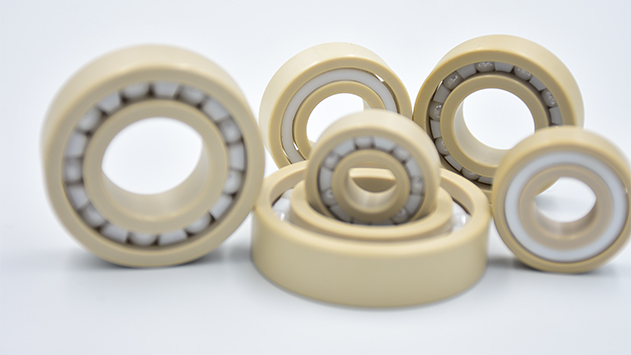

Ukukhiqizwa kwezimboni kwepulasitiki ye-PA6 nylon kusetshenziswa kabanzi ekwenziweni kwama-bearings, amagiya ayindilinga, ama-cam, amagiya e-bevel, ama-roller ahlukahlukene, ama-pulley, ama-pump impellers, ama-fan blades, amagiya e-worm, ama-propellers, ama-screws, ama-nuts, ama-gasket, ama-seal anomfutho ophezulu, ama-gasket amelana namafutha, izitsha ezimelana namafutha, izindawo zokugcina, amapayipi, i-cable sheathing, kanye nezidingo zansuku zonke kanye nefilimu yokupakisha nokunye.

I-PA6 ivame ukusetshenziswa ekubumbeni ngomjovo, ekubumbeni nge-extrusion, nakwezinye izindlela zokucubungula. Ngesikhathi sokucubungula, i-PA6 ingaba nezinkinga ezithile ezivamile, okuhlanganisa:

Ukugeleza kokuncibilika okubi: I-PA6 inobuthi obukhulu bokuncibilika, okuholela kalula ekugelezeni okubi kokuncibilika futhi kuthinte ikhwalithi yokubumba yomkhiqizo. Ukugeleza kokuncibilika kungathuthukiswa ngokulungisa izinga lokushisa lokucubungula nokwandisa ingcindezi yomjovo.

Ukuncipha okukhulu: I-PA6 izoba nokuncipha okukhulu enkambisweni yokupholisa, okuzoholela kalula kusayizi womkhiqizo ongazinzile noma ekuguqukeni. Ukuncipha kungancishiswa ngokuklama isakhiwo sesikhunta ngokuhlakanipha nokulawula isivinini sokupholisa.

Amabhamuza kanye nokuvuleka: Ekubunjweni komjovo, i-PA6 ingakhiqiza amabhamuza kanye nokugoba ngenxa yezinsalela zegesi noma ukugeleza kokuncibilika okubi, okuthinta ikhwalithi yomkhiqizo. Ukukhiqizwa kwamabhamuza kanye nokugoba kungancishiswa ngokwenza ngcono isakhiwo sesikhunta kanye nokwandisa izinga lokushisa lokuncibilika.

Ukumelana nokuguguleka kobuso: I-PA6 ivame ukuklwebheka ngesikhathi sokubumba noma ukukhipha umjovo, okuthinta ikhwalithi yomkhiqizo futhi ngaleyo ndlela kunciphisa impilo yenkonzo yomkhiqizo. Ekucutshungulweni kwe-pellets ye-PA6 kungangeza inani elifanelei-silicone masterbatch, ngokuguqulwa kwezinto ze-PA6, ukuthuthukisa ukusebenza kokucubungula kwezinhlayiya ze-PA6, ukugwema ikhwalithi yemikhiqizo ethintekile.

Ukumelana nokuguguleka kwe-SILIKE Surface Silicone Masterbatch——Ukusiza ukuthuthukiswa kwemboni yobunjiniyela bepulasitiki

I-SILIKE Silicone Masterbatch I-LYSI-407iyifomula eyenziwe nge-pelletized ene-polymer ye-siloxane enesisindo sama-molecule esingu-30% esiphezulu kakhulu esatshalaliswe ku-Polyamide-6 (PA6). Isetshenziswa kabanzi njengesithasiselo esisebenzayo sezinhlelo ze-resin ezihambisana ne-PA6 ukuthuthukisa izakhiwo zokucubungula kanye nekhwalithi yobuso, njengekhono lokugeleza kwe-resin elingcono, ukugcwaliswa nokukhululwa kwesikhunta, i-torque encane yokukhipha, i-coefficient ephansi yokungqubuzana, kanye nokumelana okukhulu kwe-mar kanye nokuklwebheka.

Yiziphi izinzuzo zokwengeza inani elifanele le-I-SILIKEI-Silicone Masterbatch LYSI-407enqubweni yokwakheka kwe-granulation?

(1) Thuthukisa izakhiwo zokucubungula okuhlanganisa ikhono lokugeleza elingcono, ukuncipha kokuvuza kwe-extrusion die, i-torque encane ye-extruder, ukugcwaliswa okungcono nokukhuliswa kokubumba

(2) Thuthukisa ikhwalithi yobuso njengokushelela kobuso kanye ne-Coefficient ephansi yokungqubuzana.

(3) Ukumelana okukhulu kokuklwebheka nokuklwebheka

(4) Ukuphuma okusheshayo, kunciphisa izinga lokukhubazeka komkhiqizo.

(5) Thuthukisa ukuzinza uma kuqhathaniswa nezinsiza zokucubungula zendabuko noma izinto zokugcoba

Yiziphi izindawo zokusetshenziswa kwe-I-SILIKE Silicone Masterbatch LYSI-407?

(1) I-PA6, i-PA66 compounds

(2) Ama-PA compounds e-fiber yengilazi

(3) Amapulasitiki obunjiniyela

(4) Ezinye izinhlelo ezihambisana ne-PA

I-silicone masterbatch yochungechunge lwe-SILIKE LYSIIngacutshungulwa ngendlela efanayo nesithwali se-resin esisekelwe kuso. Ingasetshenziswa ezinqubweni zokuxuba ezincibilikisiwe zakudala njengezikhuhli ze-Single / Twin screw, kanye nokubumba nge-injection. Kunconywa ukuxuba okungokoqobo nama-pellet e-polymer ahlanzekile.

Inani elihlukile lokwengeza linemiphumela ehlukene, uma ufuna ukuthuthukisa ukusebenza kokucubungula kanye nokusebenza kobuso bezinto zokusetshenziswa zepulasitiki zobunjiniyela, ungaxhumana ne-SILIKE, futhi singakunikeza izixazululo ezisebenzayo zokwenza imikhiqizo yakho incintisane kakhudlwana.

Tel: +86-28-83625089/+ 86-15108280799 Email: amy.wang@silike.cn

Iwebhusayithi:www.siliketech.com

Isikhathi sokuthunyelwe: Mashi-07-2024