Ungazixazulula kanjani izinkinga zokucubungula izinto ezigcina ilangabi?

Izinto ezigcina amalangabi zinkulu kakhulu emakethe emhlabeni jikelele futhi zisetshenziswa kabanzi ezimbonini ezifana nezokwakha, izimoto, izinto zikagesi, izindiza, njll. Ngokusho kombiko wocwaningo lwemakethe, imakethe yezinto ezigcina amalangabi ihlale inomkhuba omuhle wokukhula eminyakeni embalwa edlule.

Kodwa-ke, enkambisweni yokukhiqizwa kwezinto ezigcina umlilo, kuvame ukubhekana nezinkinga ezilandelayo zokucubungula:

Ukusabalala okungahambi kahle: Izinto ezivimbela ilangabi zivame ukuba khona ngesimo sezinhlayiya noma izimpushana futhi zinobukhulu obukhulu kanye namandla adonsela phansi athile, okwenza kube nzima ukusabalala ngokulinganayo ezintweni eziyisisekelo ngesikhathi sokucubungula. Ukusabalala okungahambi kahle kuzoholela ekusabalaleni okungalingani kwento evimbela ilangabi ezintweni, okuthinta umphumela wento evimbela ilangabi.

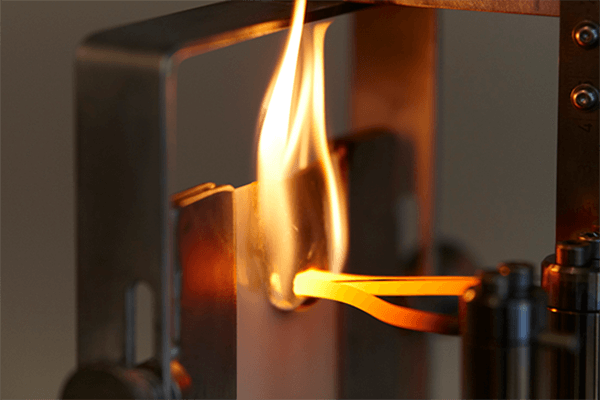

Ukuzinza kokushisa okubi: Ezinye izinto ezigcina ilangabi zizobola emazingeni okushisa aphezulu noma uma zivezwa emazingeni okushisa aphezulu isikhathi eside, zilahlekelwe umphumela wazo wokungagcini ilangabi futhi zikhiqize ngisho nezinto eziyingozi. Ngakho-ke, kubalulekile ukulawula izinga lokushisa lokushisa kanye nesikhathi sokucubungula ngesikhathi sokucubungula ukuqinisekisa ukuzinza kokushisa kwezinto ezigcina ilangabi.

Izinkinga zokuhambisana: Kungase kube nezinkinga zokuhambisana phakathi kwe-flame retardant kanye nezinto eziyisisekelo, okungukuthi, ukuhambisana phakathi kwalokhu okubili akunamandla ngokwanele ukuhlangana ngempumelelo. Lokhu kuzoholela ekuhlakazekeni okubi kwe-flame retardant kanye nokusebenza okungagculisi kwe-flame retardant.

Ithonya ezimpahleni zezinto: Ukwengeza into evimbela ilangabi kakhulu kungaholela ekunciphiseni izakhiwo zemishini nezikagesi zezinto, futhi kubangele nokuqhekeka kanye nokuguquka kwezinto. Ngakho-ke, kubalulekile ukulawula ngokufanele inani lezinto ezingeziwe ngokwezinto ezithile kanye nezici zento evimbela ilangabi enkambisweni.

Ukuze kunqotshwe lezi zinkinga zomshini, izinyathelo ezilandelayo zingathathwa:

Ukukhethwa kwendlela yokucubungula efanelekile: Ngokwezinto ezithile kanye nezakhiwo zokuvimbela umlilo, khetha indlela yokucubungula efanelekile, njengokukhipha, ukubumba ngomjovo, ukubumba ngokucindezela njalo njalo. Izindlela ezahlukene zokucubungula zinemiphumela ehlukene ekuhlakazekeni, ukuhambisana kanye nokuzinza kokushisa kwezinto ezivimbela umlilo.

Lawula inani lezithako: Lawula ngokufanele inani lezithako ezivimbela ilangabi ezengeziwe, ukuze ugweme ukusetshenziswa ngokweqile kwezithako ezivimbela ilangabi okuholela ekwehleni kokusebenza kwezinto.

Lungiselela ukuhlakazeka kwezinto ezigcina ilangabi: Ukusetshenziswa kwezinto ezigcina ilangabi noma izinto ezishintsha ubuso kungathuthukisa ukuhlakazeka kwezinto ezigcina ilangabi futhi kwandise ukulingana kwazo ezintweni.

Ukukhethwa kwezinto ezivimbela umlilo ezifanele: Ngokwezidingo ezithile zohlelo lokusebenza, khetha izinto ezivimbela umlilo ezifanele, ucabangele izici ezifana nokuqina kwazo kokushisa, ukuhambisana kwazo kanye nokusabalala kwazo.

Ama-Hyperdispersant e-SILIKE – Aklanyelwe ngokukhethekile ukusabalala kwama-flame retardants. Lolu chungechunge lwemikhiqizo lufanelekela ama-resin avamile e-thermoplastic, i-TPE, i-TPU kanye nezinye i-thermoplastic elastomers. Ngaphezu kwama-flame retardants, lolu chungechunge lwemikhiqizo lufanelekela nama-masterbatches noma izinto ezihlanganisiwe kakhulu ezisakazwe kusengaphambili.

- Ukugcoba okuhle komshini

- Ukusebenza kahle kokucubungula okuthuthukisiwe

- Ukuhambisana okuthuthukisiwe phakathi kwempuphu kanye ne-substrate

- Akukho mvula, kuthuthukisa ukushelela komphezulu

- Ukusabalala okuthuthukisiwe kwempuphu evimbela ilangabi, ukuvimbela ilangabi okusebenzisanayo

Isikhathi sokuthunyelwe: Septhemba-26-2023