Ukuqonda i-Fiber ne-Monofilament:

I-Fiber kanye ne-Monofilament kuyizintambo noma imicu eyodwa, eqhubekayo yento ethile, ngokuvamile i-polymer yokwenziwa njenge-nylon, i-polyester, noma i-polypropylene. Lezi zintambo zibonakala ngesakhiwo sazo sengxenye eyodwa, ngokungafani nemicu eminingi equkethe imicu eminingi esontekile noma eqoqwe ndawonye.

I-Fiber kanye ne-Monofilament zithola ukusetshenziswa ezimbonini ezahlukahlukene, okuhlanganisa izindwangu, ukudoba, kanye nezinqubo zezimboni. Ezindwangu, izindwangu ze-monofilament zingasetshenziswa ekusetshenzisweni njengezindwangu eziqinile, amanetha, kanye ne-mesh. Ekudobeni, imigqa ye-monofilament ivame ukusetshenziswa ekudobeni nasekudobeni ngebhizinisi ngenxa yamandla ayo, ukuguquguquka, kanye nokumelana nokuklwebheka. I-monofilament isetshenziswa futhi kumongo we-sutures yezokwelapha, lapho imicu eyodwa yezinto ezihambisana ne-bio isetshenziselwa ukuthunga amanxeba noma ukusikwa kokuhlinzwa.

Ngokuvamile, Embusweni oguquguqukayo wokucubungula i-polymer, ukufuna ukusebenza kahle kanye nekhwalithi ekukhishweni kwe-fiber noma i-monofilament akupheli. Abakhiqizi balwela izixazululo ezintsha zokuthuthukisa ukusebenza kokukhiqiza, ukunciphisa isikhathi sokungasebenzi, kanye nokunciphisa imfucuza. Le nqubo ebalulekile yokukhiqiza iguqula ama-resin e-polymer abe yimicu eqhubekayo eyenzelwe izinhlelo ezahlukene, kusukela ezindwangu kanye ne-sutures yezokwelapha kuya ezingxenyeni zezimboni.

Izinselele ku-FiberfuthiUkukhishwa kwe-Monofilament:

Ukwakheka kwe-die building, ukungcoliswa kwesikrini, kanye nokuphuka kwe-strand kuba yizithiyo kubakhiqizi, okuthinta ikhwalithi yomkhiqizo wokugcina kanye nokwenyuka kwesikhathi sokungasebenzi kanye nezindleko. Ama-fluoropolymers endabuko kanye namakhemikhali aqukethe i-PFAS asetshenziswe njengeizinsiza zokucubungula i-polymer ezisebenzayo (ama-PPA)Kodwa, njengoba imithetho emisha ezayo eYurophu nase-USA ibeka imingcele kanye nemikhawulo ekusetshenzisweni kwama-fluoropolymers, kanye namakhemikhali aqukethe i-PFAS, abakhiqizi bafuna ezinye izindlela ezihambisana nale mithetho ezayo ngaphandle kokuphazamisa ukusebenza.

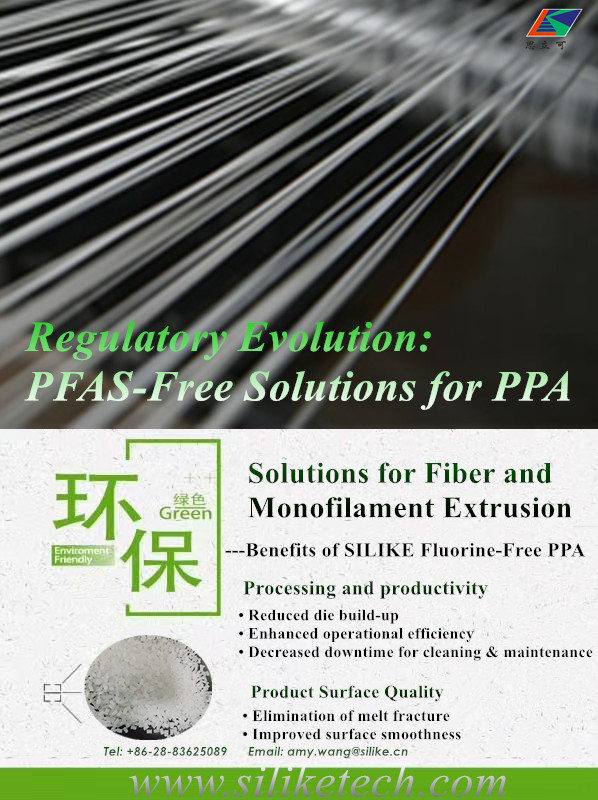

I-PPA yamahhala ye-SILIKE's PFASIsixazululo:

Izinsiza Zokucubungula I-Polymer Ezingenayo i-PFAS ze-SILIKEkuvela njengesixazululo esibalulekile sezinselele ezibhekene nazo.Izinsiza Zokucubungula I-Polymer Ezingenayo I-Fluorine (PPA) SILIMER 5090ihambisana nemithethonqubo ye-EU ezayo, igwema imikhawulo kanye nokuvinjelwa kwama-fluoropolymers kanye namakhemikhali aqukethe i-PFAS.

Isixazululo sethu esiyingqayizivele siqinisekisa ukukhiqizwa kwe-polymer okunesibopho, sibeka phambili ukusimama ngaphandle kokubeka engcupheni ikhwalithi noma ukusebenza kahle.

Izinhlelo zokusebenza ezivamile ezizuza ngokusetshenziswa zifaka:

• Ifilimu eshaywayo nedlalwa ngabadlali

• Ukukhishwa kwefilimu enezingqimba eziningi

• Ukukhishwa kwekhebula kanye nepayipi

• Ukukhishwa kwe-Fiber kanye ne-Monofilament

• Ukucubungula ngamakhemikhali

• Ukukhishwa kweshidi

• Ukuhlanganisa

Ukuvula Indlela eya ku-Optimal Fiber kanye ne-Monofilament Extrusion!

Emkhakheni wezinhlayiya ezincane kanye nomthamo omkhulu okhiqiza imicu emincane kakhulu, ukwakheka kwezinhlayiya kanye nesikrini, ukuxhuma izinhlayiya, kanye nokuphuka kwezintambo kuletha izinselele eziholela ekuchithekeni nasekuphelelweni kwesikhathi. Kubhekana kanjani nezinselele ze-Fiber kanye ne-Monofilament Extrusion?

Vula Ukusebenza Kahle Ekukhiqizweni Kwe-Fiber kanye ne-Monofilament nge I-PPA yamahhala ye-SILIKE's PFAS!

1. Ukunciphisa Ukwakheka Kwephekhi Yesihenqo Neyesihenqo:Ukwakhiwa okusha kweIzinsiza Zokucubungula I-SILIKE-Free Polymer (PPA) SILIMER 5090ukunciphisa ngempumelelo ukuqongelela kokungcola kanye nezinsalela ze-polymer kuma-dies amancane kanye nama-screen packs. Lokhu kunciphisa kuqinisekisa inqubo yokukhipha ebushelelezi futhi kuvimbela isidingo sokuhlanza nokulungisa njalo.

2. Ukuvimbela Ukufakwa Kwe-Die Plug: Indlela eyingqayizivele yokwakheka Izinsiza Zokucubungula I-SILIKE-Free Polymer (PPA) SILIMER 5090kusiza ukuvimbela ukufakwa kwe-die plug, inkinga evamile ephazamisa ukugeleza okuqhubekayo kwe-polymer nge-die. Lokhu kuholela ekukhishweni okuqhubekayo kanye nemikhiqizo yokugcina esezingeni eliphezulu.

3. Ukunciphisa Ukuphuka Kwezinsika: Ngokuthuthukisa izakhiwo zokugeleza kwe-polymer,Izinsiza Zokucubungula I-SILIKE-Free Polymer (PPA) SILIMER 5090kunegalelo ekunciphiseni ukuphuka kwezintambo ngesikhathi sokukhipha. Lokhu akugcini nje ngokuthuthukisa ukusebenza kahle kokukhiqiza kodwa futhi kunciphisa imfucuza, okuholela ekongeni izindleko kubakhiqizi.

4. Ukusetshenziswa Kahle Kwezindleko Nokunciphisa Isikhathi Sokungasebenzi: Inhlanganisela yokwakheka kwe-die kanye ne-screen pack encishisiwe, ukuvimbela ukuvalwa kwe-die, kanye nokunciphisa ukuphuka kwe-strand ndawonye kunegalelo ekongeni izindleko ezinkulu kanye nesikhathi esincishisiwe sokungasebenzi. Abakhiqizi bangafinyelela inani eliphezulu lokukhiqiza ngokusebenza kahle okuthuthukisiwe.

Ukulungele ukuphakamisa izinqubo zakho zokukhipha? Hlola amandla e-Usizo Lokucubungula I-Polymer olungenayo i-PFAS lwe-SILIKE SILIMER 5090ukusebenza okuphezulu ekukhiqizweni kwe-fiber kanye ne-monofilament.

Kodwa akusikho lokho kuphela – Thola Izinhlelo Zokusebenza Ezingenamkhawulo zeIzinsiza Zokucubungula I-SILIKE-Free Polymer (PPA) SILIMER 5090ngale kwe-Fiber kanye ne-Monofilament Extrusion, Kusukela ku-Blown film, ifilimu ehlanganisiwe, Ikhebula, amapayipi, i-Fiber, kanye ne-Monofilament Extrusion, i-Sheet extrusion, ehlanganiswa ne-petrochemicals, i-metallocene polypropylene, noma i-metallocene PE.Izinsiza Zokucubungula I-Polymer Ezingenayo i-PFAS ze-SILIKEiyisihluthulelo sakho sokwenza kahle kakhulu i-Compliance Meets Innovation, ihambisana nemithethonqubo ye-EU ezayo, igwema imikhawulo kanye nokuvinjelwa kwama-fluoropolymers kanye namakhemikhali aqukethe i-PFAS. Lesi sixazululo esisha siqinisekisa ukukhiqizwa kwe-polymer okunesibopho ngaphandle kokubeka engcupheni ikhwalithi noma ukusebenza kahle, sithembisa izinzuzo eziningi zokukhiqiza.

Xhumana ne-SILIKE namuhla ukuze uthuthukise ukucubungula kwakho i-polymer, uthuthukise umkhiqizo, futhi uphakamise ikhwalithi yomkhiqizo!

Tel: +86-28-83625089 Email: amy.wang@silike.cn

Iwebhusayithi:www.siliketech.com

Isikhathi sokuthunyelwe: Jan-10-2024