Emakethe yokupakisha yanamuhla, abakhiqizi banikezwa ukubaluleka kokuthuthukisa ukusebenza kwamafilimu abo epulasitiki. Lo mgomo uvame ukuvinjelwa yizinselele ezifana nokuvimba amafilimu ngesikhathi sokucubungula nokuphatha, okungaphazamisa imigqa yokukhiqiza futhi kunciphise ukusebenza kahle. Ngaphezu kwalokho, ukungashibiliki ngokwanele kungabangela izinkinga ezifaka ukuphathwa okungafanele, ukunamathela, kanye nokupakisha okungaguquki, ngaleyo ndlela kuthinte kabi ikhwalithi yobuhle kanye nokusebenza komkhiqizo wokugcina.

Amasu Okunqoba Izinselele Ekukhiqizweni Kwamafilimu Epulasitiki

Ukubaluleka Kwama-Slip kanye nama-Antiblock Agents kumafilimu epulasitiki

Ama-slip kanye nama-antiblock agents ayizithasiselo ezibalulekile ezisetshenziswa ekwakhiweni kwamafilimu epulasitiki. Lawa ma-agent abalulekile ekwandiseni ukusebenza, ukuphathwa, kanye nezici zokucubungula amafilimu, ikakhulukazi ekufakweni kwamaphakheji. Isigaba esilandelayo sinikeza umbono jikelele wemisebenzi yawo futhi sigcizelela ukubaluleka kwawo enkambisweni yokukhiqiza.

Ama-Slip Ejenti

Ama-slip agent ayizithasiselo ezinciphisa ukungqubuzana phakathi kwezingqimba zefilimu yepulasitiki noma phakathi kwefilimu nezinye izindawo. Zisiza ekuthuthukiseni ukuphathwa nokucubungula kalula kwefilimu, ikakhulukazi ngesikhathi sokukhiqiza, ukuthuthwa, kanye nokusetshenziswa.

Imisebenzi kanye nezinzuzo zama-Slip Ejenti:

I-Reduced Coefficient of Friction (COF): Umsebenzi oyinhloko wama-slip agents ukwehlisa i-coefficient of friction (COF) phakathi kwezindawo zefilimu yepulasitiki. Lokhu kwenza ifilimu ibe lula ukuyiphatha, ikakhulukazi ezinqubweni ezenzakalelayo njengemigqa yokupakisha esheshayo.

Ukucutshungulwa Okuthuthukisiwe: Ngokunciphisa ukungqubuzana, ama-slip agents avimbela ifilimu ukuthi inamathele kuma-roller noma emishinini ngesikhathi sezinqubo zokukhipha noma zokushisa, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kokukhiqiza.

Ukusebenza Okuthuthukisiwe: Izinto ezishelelayo zithuthukisa ikhono lefilimu lokushelela phezu kwezindawo, okwenza kube lula ukuvula amaphakheji, kuncishiswe amathuba okunamathela, futhi kuthuthukiswe ukuqina kwamaphakheji.

Ama-ejenti avamile okushelela:

1. Ama-Amide e-Fatty Acid (isib. i-Erucamide, i-Oleamide): Lawa ama-slip agent asetshenziswa kakhulu. Athuthela ebusweni befilimu futhi anciphise ukungqubuzana kobuso.

2. Ama-Compounds Asekelwe ku-Silicone: Ama-ejenti okushelela e-silicone avame ukusetshenziselwa ukuthuthukisa izakhiwo zokushelela futhi anikeze izinga eliphezulu lokusebenza ezinhlelweni zokusebenza ezidinga ukusebenza kahle okukhulu.

Ama-Antiblock Ejenti

Ama-antiblock agents ayengezwa ukuvimbela ukunamathela noma ukunamathela kwezingqimba zefilimu yepulasitiki ngesikhathi sokugcina, ukuphatha, noma ukuthuthwa. Ngaphandle kwama-antiblock agents, ifilimu inganamathelana, okubangela ubunzima ekukhululekeni noma ekupakisheni.

Imisebenzi kanye nezinzuzo zama-Antiblock Agents:

Ukuvimbela Ukunamathela Kwezingqimba: Umsebenzi oyinhloko wama-antiblock agents ukudala izikhala ezincane noma izindawo ezimahhadlahhadla efilimini, ukuvimbela izingqimba ngazinye ukuthi zinganamatheli ndawonye.

Ukuthuthukiswa Kokuvuleka: Emiqulwini yefilimu, ama-antiblock agent asiza ukugcina ubuqotho bezingqimba zefilimu ngesikhathi sokuvuleka, okwenza kube lula ngemishini yokupakisha ezenzakalelayo ukuphatha izinto.

Ukunamathela Okuncishisiwe Komphezulu: Ama-antiblock agents aqinisekisa ukuthi amafilimu angafakwa noma aboshwe ngaphandle kokudala izinkinga ezifana nokuvimba noma ukuchoboza amafilimu, okungaholela ekungakhiqizweni kwesikhathi noma ekulahlekeni kwezinto ezibonakalayo.

Ama-Antiblock Ejenti Avamile:

1. I-Silica (SiO₂): I-Silica iyi-ejenti yokulwa nokuvimba esetshenziswa kakhulu kumafilimu epulasitiki. Inikeza indlela ephumelelayo yokunciphisa ukuxhumana kobuso phakathi kwezingqimba.

2. I-Talc: I-Talc ingenye into esetshenziswa kabanzi yokulwa nokuvimba. Isebenza ngokwandisa ukujiya kobuso nokuvimbela amafilimu ukuthi anganamatheli ndawonye.

3. I-Calcium Carbonate (i-CaCO₃): I-Calcium carbonate isetshenziswa ngezikhathi ezithile njenge-antiblock agent, ikakhulukazi kumafilimu lapho ukonga izindleko kuyinto eza kuqala, yize ingasebenzi kahle kune-silica kwezinye izimo.

Ama-Slip kanye nama-Antiblock Ejenti Ahlanganisiwe

Kumafilimu amaningi, kokubili ama-slip kanye nama-antiblock agents asetshenziswa ndawonye ukuze kuthuthukiswe ukusebenza kwefilimu. Lawa ma-agent ahlinzeka ngezinzuzo ezengeziwe, ikakhulukazi ezinhlelweni lapho amafilimu ephathwa khona ngesivinini esikhulu noma kudingeka amelane nokunamathela phakathi kwezingqimba. Inhlanganisela efanele iqinisekisa ukuthi ifilimu kulula ukuyicubungula futhi kulula ukuyiphatha, kuyilapho futhi igcina ukusebenza kwayo kanye nobuqotho.

Izinzuzo Eziyinhloko Zokuhlanganisa Ama-Slip kanye nama-Antiblock Agents:

Ukucubungula Okushelelayo: Ngokuqinisekisa ukuthi ifilimu ihamba kahle ezinqubweni zokukhiqiza nokuphatha, kokubili ama-slip kanye nama-antiblock agents anciphisa ukucindezeleka komshini efilimini.

Ikhwalithi Yomkhiqizo Ethuthukisiwe: Ngala ma-ejenti, umkhiqizo wokugcina uzoba nokucaca okuthuthukisiwe kokukhanya, ukunamathela okuncane kwefilimu kuya efilimini, kanye nokuphathwa okulula kakhulu, okubalulekile ekufakweni kwephakeji.

Ukusebenza Kahle Kwezindleko: Inhlanganisela efanele yama-slip agents kanye nama-antiblock agents inganciphisa imfucuza yezinto ezibonakalayo, ithuthukise ukusebenza kahle kokukhiqiza, futhi ithuthukise ukusebenza komkhiqizo wokugcina wefilimu.

Ngenxa yesidingo esikhulayo sezixazululo zefilimu ezisebenzayo ezinikeza ukuthambisa okushisa okuphezulu, ukumelana nemvula, ukuvimbela okusebenzayo, kanye nomthelela omncane ekuphrinteni, i-Silike yakha uchungechunge lwemikhiqizo emihlanu ehlukahlukene eyenzelwe ukuhlangabezana nezidingo ezishintshayo zemboni yamafilimu.

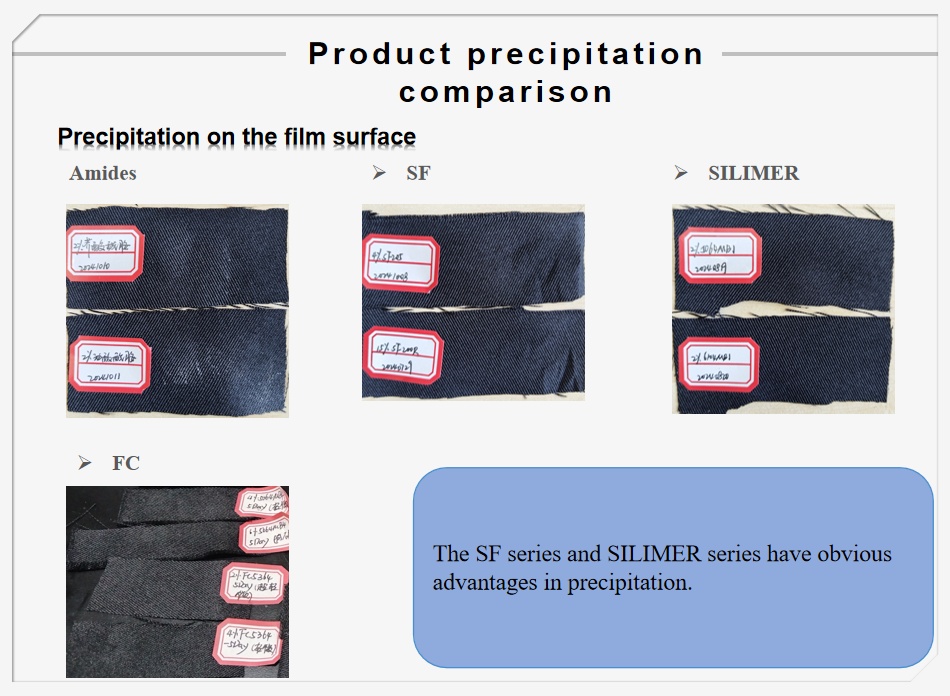

1. I-SILIKEI-SILIMER Series super slip kanye ne-masterbatch yokulwa nokuvimba:Lokhu kusezingeni eliphezului-super slip kanye ne-masterbatch elwa nokuvimbaYakhelwe ngobuchwepheshe amafilimu epulasitiki. Ngokufaka i-polymer ye-silicone eguquliwe, uchungechunge lwe-SILIMER lubhekana nezinselele ezivamile ezihambisana nezinto ezibushelelezi zendabuko, njengokuna kwemvula kanye nokunamathela okushisa okuphezulu. Lesi sixazululo esisha sithuthukisa kakhulu izakhiwo zokulwa nokuvimba kanye nokushelela, okunciphisa ngempumelelo ama-coefficients okungqubuzana angaguquki kanye naguquguqukayo ngesikhathi sokucubungula. Ngenxa yalokho, ubuso befilimu bufinyelela ukushelela okumangalisayo. Ngaphezu kwalokho, i-SILIMER igcina ukuhambisana okuhle kakhulu nama-resin e-matrix, iqinisekisa ukuthi akukho ukuna kwemvula noma ukunamathela ngenkathi igcina ukubonakala kwefilimu. Isetshenziswa kakhulu ekukhiqizeni amafilimu e-polypropylene (PP) kanye ne-polyethylene (PE).

2.Uchungechunge lwe-SILIKE SFI-Super Slip Masterbatch: Lolu chungechunge lwenzelwe ngqo izinhlelo zokusebenza zefilimu yepulasitiki, lune-polymer ye-silicone eguquliwe ngokukhethekile njengesithako esisebenzayo. Uchungechunge lwe-SF luxazulula ngempumelelo imikhawulo ebalulekile ehlangana nama-slip agents avamile, njengokunisela okuqhubekayo kusuka ebusweni befilimu, ukwehla kokusebenza kokunisela ngokuhamba kwesikhathi, kanye nephunga elingathandeki emazingeni okushisa aphezulu. Ngezimpawu zokunisela eziphakeme kanye nokuvinjelwa, uchungechunge lwe-SF lugcina i-coefficient ephansi yokungqubuzana (i-COF) ngenkathi luvimbela noma yikuphi ukunisela. Lokhu kwenza kube ukukhetha okuhle kokukhiqiza amafilimu e-BOPP, amafilimu e-CPP, amafilimu e-TPU, amafilimu e-EVA, amafilimu okusakaza, kanye nezingubo zokufaka.

3. I-masterbatch yokulwa nokuvimba ye-SILIKE FA Series:Le masterbatch entsha yokulwa nokuvimba iqukethe izithako ezintathu ezisebenzayo: i-silica, i-aluminosilicate, kanye ne-PMMA. Yenzelwe ngqo ukuhambisana nezinhlobo eziningi zamafilimu, kufaka phakathi amafilimu e-BOPP, amafilimu e-CPP, namafilimu aqondile ayisicaba. Uchungechunge lwe-FA luthuthukisa kakhulu izakhiwo zokulwa nokuvimba kanye nokushelela, ngenxa yesakhiwo salo esikhethekile esiqinisekisa ukuhambisana okuhle kakhulu.

4. Uchungechunge lwe-SILIKE FC:

- Izici Eziyinhloko: Ubuso obubushelelezi, ukukhishwa okuphansi

- Izithako Eziyinhloko Ezisebenzayo: I-Copolymer polysiloxane (i-silicone wax) kanye ne-amide

5. Uchungechunge lwe-SILIKE FSE:

- Izici Eziyinhloko: Ukushelela okumangalisayo, ukusebenza kahle kwezindleko

- Isithako Esiyinhloko Esisebenzayo: I-amide ehlanzekile kakhulu

Ingabe ubhekene nezinselele zokuvaleka kwamafilimu noma ukubhekana nokungasebenzi kahle emigqeni yakho yokukhiqiza?

Thola ukuthi ama-ejenti ethu athuthukile okushelelayo kanye nama-antiblock angathuthukisa kanjani ukusebenza kwamafilimu akho epulasitiki, aqinisekise ukucutshungulwa okubushelelezi kanye nekhwalithi yomkhiqizo ethuthukisiwe.

Kusukela ekunciphiseni ukungqubuzana kuya ekuvimbeleni ukunamathela kwengqimba kanye nokunciphisa ukuna kwempuphu, izixazululo zethu—njenge-SILIKE SILIMER kanye ne-SF Series—zinikeza izinzuzo ezingenakuqhathaniswa zemigqa yokupakisha esheshayo, okwenza ukukhiqizwa kwakho kusebenze kahle futhi kube ngcono.

Ngaphezu kwalokho, iSilike izibophezele ekuzinzeni ngobubanzi bayo be-PPAS-Free PPA yezinhlelo zokusebenza zamafilimu. Lezi zinketho ezingenayo i-PFAS azigcini nje ngokuthuthukisa ukusebenza kodwa futhi zisekela nemikhuba enesibopho semvelo ekukhiqizweni kwamafilimu. Ngalezi zixazululo ezintsha, iSilike izinikezele ekusizeni imboni ukuthi ithuthukele ekusaseni elizinzile neliphumelelayo.

Uma ufuna ukuthuthukisa ukukhiqizwa kwefilimu yakho yepulasitiki, i-SILIKE inikeza uhla olubanzi lwezixazululo. Kungakhathaliseki ukuthi udingaizithasiselo zokushelela zamafilimu epulasitiki, ama-slip agents amafilimu e-polyethylene, nomaama-hot slip agents asebenza kahle angafuduki,sinemikhiqizo efanele izidingo zakho. Izithasiselo zethu ezingashukumiyo zokushelela kanye nezokulwa nokuvimba zenzelwe ukuthuthukisa ukusebenza kanye nokwenza ngcono inqubo yakho yokukhiqiza.

Sikumema ukuthi uxhumane ne-SILIKE ukuze uthole ukubonisana, lapho singaxoxa khona ngendlela yethuukushelela okuphezulu kanye nama-masterbatch alwa nama-block can contribute to achieving outstanding results in your plastic film production. Email us at amy.wang@silike.cn or visit our website at www.siliketech.com to learn more.

Isikhathi sokuthunyelwe: Ephreli-30-2025