Kuyini i-Polyolefin Blown Film Extrusion?

I-polyolefin blowed film extrusion isetshenziswa kabanzi ukukhiqiza amafilimu okupakisha ukudla, izimpahla zabathengi, ama-liner ezimboni, amafilimu ezolimo, kanye nokupakisha okuvikelayo.

Ukukhiqizwa kwamafilimu anamuhla aqhumayo kudinga kakhulu amafilimu amancane, amazinga aphezulu okukhipha, ikhwalithi yobuso obubushelelezi, kanye nokukhishwa okuzinzile kwesikhathi eside.

Ukuze kufezwe le migomo, amaprosesa avame ukusebenzisa ama-LLDPE, mLLDPE, LDPE, kanye nama-polyolefin e-metallocene, okubeka izidingo eziphezulu ekucutshungulweni kwe-extrusion.

Izinselele Ezijwayelekile Zokucubungula Ekukhishweni Kwefilimu Eqhumayo

Njengoba isivinini sokukhiqiza sanda futhi ubukhulu befilimu buncipha, abakhiqizi befilimu abakhungathekile bavame ukuhlangana nalokhu:

× Ukuqhekeka okuncibilikayo (isikhumba soshaka) ngesivinini esiphezulu

×Ukugeleza kokuncibilika okubi kanye nokuziphatha okungazinzile kwama-bubble

×Ukwakheka kakhulu kwama-die kanye nokuhlanza njalo

× Ukwanda kwe-torque kanye nengcindezi yokukhipha

×Ukuthembela okuqinile ezinsizeni zokucubungula i-PPA ene-fluorine

Lezi zinkinga zikhawulela ukusebenza kahle komkhiqizo, ukubukeka kwendawo, kanye nokuzinza kokusebenza.

Kungani ama-PPA afakwe i-Fluorinated ethathelwa indawo kuzinhlelo zokusebenza zefilimu ezifakwe i-Blown?

Izinsiza zokucubungula i-polymer ene-fluorine bezisetshenziswa ngokwesiko ukuthuthukisa ukugeleza kokuncibilika nokucindezela ukuqhekeka kokuncibilika.

Kodwa-ke, ingcindezi ekhulayo yokulawula i-PFAS, ikakhulukazi ekufakweni nasekusetshenzisweni kokuxhumana nokudla, iqhubela imboni ezindleleni ezingezona i-fluorine.

Abakhiqizi bamafilimu abadumile kudingeka balinganisele:

•Ukusebenza kokukhipha okusheshayo okuphezulu

•Ukuthobela imithetho kanye nokusimama

•Ukuthembeka kokwakheka kwesikhathi eside

Isixazululo se-PPA samahhala se-SILIKE PFAS se-Blown Film Extrusion

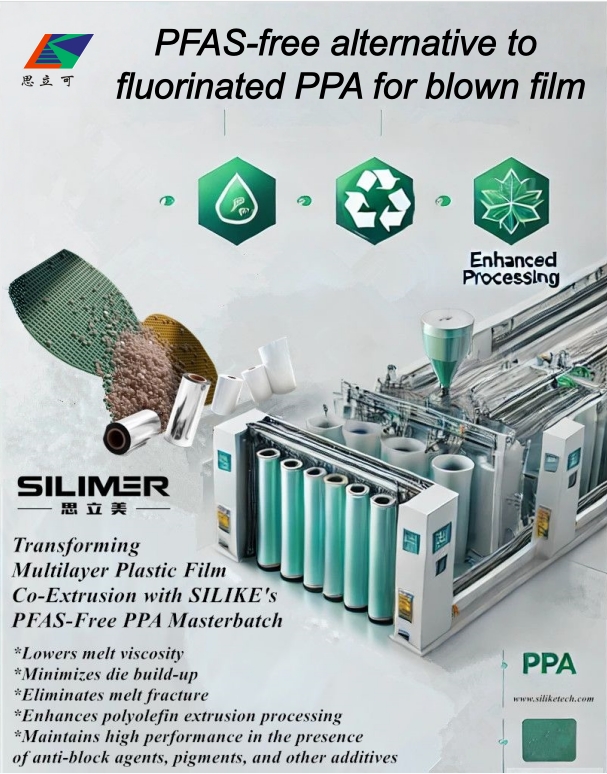

I-SILIKE SILIMER PFAS-Free PPA Masterbatchkuyintousizo lokucubungula olungenayo i-fluorineyakhelwe ukukhishwa kwe-polyolefin, okuhlanganisa nokusetshenziswa kwefilimu eqhumile.

Ngezinga eliphansi lokwengeza, i-SILIMER isiza abaprosesa ukuthi bafinyelele ekukhishweni okuzinzile nokuphumayo okuphezulu ngaphandle kwe-PFAS.

Izinzuzo Eziyinhloko Zokusiza Ukucubungula Okungenayo i-SILIKE PFAS ku-Blown Film Extrusion:

√Ukugeleza kokuncibilika okuthuthukisiwe kanye nokuqina kokucubungula

√Ukuqeda ngempumelelo ukuqhekeka okuncibilikile (isikhumba soshaka)

√Ukwehla kokwakheka kwama-die kanye nezikhawu zokuhlanza ezinde

√I-torque ephansi yokukhipha kanye nengcindezi

√Ikhwalithi yobuso befilimu ebushelelezi nefanayo

Izicelo Ezijwayelekile

•Amafilimu afuthwe nge-Polyolefin (PE / LLDPE / mLLDPE)

•Amafilimu okupakisha amancane

•Ukudla kanye nokupakishwa kwezimboni

•Amafilimu ezolimo nawokuvikela

Kungani Ukhetha i-SILIKE njengoMhlinzeki we-PPA ongenazo i-PFAS?

With over 20 years of expertise in silicone-modified polymer additives, SILIKE offers PFAS-free processing solutions customized to address the challenges of modern blown film extrusion. If you are seeking an alternative to fluorinated PPA, contact amy.wang@silike.cn to obtain our Blown film processing aid – Fluorine-free processing aid. Or,vakashela iwebhusayithi:www.siliketech.com to funda kabanzi mayelanaI-SILIMER PFAS kanye nezixazululo ezihlukile ezingenayo i-fluorine!

Imibuzo Evame Ukubuzwa Ngokucutshungulwa Kwefilimu Eqhumayo (i-PPA Engenayo i-PFAS)

Umbuzo:Ukuqhekeka okuncibilikayo kungasuswa kanjani ekukhishweni kwefilimu eqhumile?

Impendulo:

Ukuqhekeka kokuncibilika ekukhishweni kwefilimu eqhumile kubangelwa ukucindezeleka okuphezulu kokusika odongeni lwedayi, ikakhulukazi ngamanani aphezulu okukhipha.

Ukusebenzisa i-usizo lokucubungula i-polymer tIsigqoko sinciphisa ukungqubuzana okuncibilikayo kuyisisombululo esisebenzayo.

Amaprosesa amaningi manje asebenzisa ama-PPA angenayo i-PFAS, njenge-SILIKE SILIMERI-SILIKE SILIMER I-PPA engena-fluorine,ukuqeda ukuqhekeka kokuncibilika ngenkathi kugcinwa ukuhambisana nemithetho.

UmbuzoKungani izinsiza zokucubungula zidingeka emigqeni yamafilimu anamuhla aqhumile?

Impendulo:

Ukukhiqizwa kwamafilimu anamuhla aqhumayo kudinga amafilimu amancane kanye nomkhiqizo ophezulu, ngokuvamile kusetshenziswa ama-mLLDPE nama-metallocene polyolefins.

Lezi zinto zithuthukisa amandla kodwa zinciphisa ukuzinza kokucubungula, okwenza izinsiza zokucubungula zibe zibalulekile ekukhishweni okuqhubekayo.

Impendulo:

Ama-PPA angenayo i-PFAS asekelwe kubuchwepheshe be-polymer obuguqulwe yi-silicone asetshenziswa kabanzi njengezindlela ezihlukile.

I-SILIKE SILIMER PFAS-Free PPAS yenzelwe ukukhishwa kwefilimu eqhunyiswe yi-polyolefin futhi inikeza ukusebenza okuzinzile, okuphuma kakhulu.

Umbuzo: Do Ama-PPA angenayo i-PFASkuthinta izakhiwo zemishini zefilimu eqhumile?

Impendulo:

Cha. Ama-PPA angenazo i-PFAS aklanywe kahle awathinti kabi amandla efilimu, ukusebenza kokuvala, noma ukubukeka.

Isikhathi sokuthunyelwe: Disemba 31-2025