Isingeniso kuma-Polyolefins kanye ne-Extrusion yeFilimu

Ama-Polyolefin, uhlobo lwezinto ezinkulu ezakhiwe ngama-molecular ezenziwe ngama-olefin monomers njenge-ethylene ne-propylene, angamapulasitiki akhiqizwa futhi asetshenziswa kakhulu emhlabeni jikelele. Ukusabalala kwawo kuvela ekuhlanganisweni okuyingqayizivele kwezakhiwo, okuhlanganisa izindleko eziphansi, ukucutshungulwa okuhle kakhulu, ukuzinza kwamakhemikhali okuvelele, kanye nezici zomzimba ezifanelana kahle. Phakathi kokusetshenziswa okuhlukahlukene kwama-polyolefin, imikhiqizo yamafilimu ibambe isikhundla esibalulekile, isebenza imisebenzi ebalulekile ekupakisheni ukudla, izembozo zezolimo, ukupakisha kwezimboni, imikhiqizo yezokwelapha neyokuhlanzeka, kanye nezimpahla zansuku zonke ezisetshenziswayo. Ama-resin e-polyolefin avame kakhulu asetshenziswa ekukhiqizeni amafilimu afaka i-polyethylene (PE) - ehlanganisa i-Linear Low-Density Polyethylene (LLDPE), i-Low-Density Polyethylene (LDPE), kanye ne-High-Density Polyethylene (HDPE) - kanye ne-polypropylene (PP).

Ukukhiqizwa kwamafilimu e-polyolefin kuncike kakhulu kubuchwepheshe bokukhipha, kanti i-Blown Film Extrusion kanye ne-Cast Film Extrusion kuyizinqubo ezimbili eziyinhloko.

1. Inqubo Yokukhipha Ifilimu Eqhumayo

Ukukhishwa kwefilimu eqhumayo kungenye yezindlela ezivame kakhulu zokukhiqiza amafilimu e-polyolefin. Isimiso esiyisisekelo sihilela ukukhipha i-polymer encibilikisiwe iqonde phezulu nge-annular die, kwakha i-parison encane enodonga oluncane. Ngemva kwalokho, umoya ocindezelwe ufakwa ngaphakathi kwale parison, okwenza ukuthi ifuthwe ibe yibhamuza elinobubanzi obukhulu kakhulu kunobo be-die. Njengoba ibhamuza likhuphuka, lipholiswa ngenkani futhi liqiniswe yindandatho yomoya yangaphandle. Ibhamuza elipholile libe seligoqwa yisethi yama-nip rollers (ngokuvamile ngohlaka olugoqekayo noma uhlaka lwe-A) bese lidonswa ama-traction rollers ngaphambi kokuba liboshwe ku-roll. Inqubo yefilimu eqhumayo ivame ukukhiqiza amafilimu anombono we-biaxial, okusho ukuthi abonisa ibhalansi enhle yezakhiwo zemishini kokubili isiqondiso somshini (MD) kanye nesiqondiso esiphambeneyo (TD), njengamandla okudonsa, ukumelana nokuklebhuka, kanye namandla okushaya. Ubukhulu befilimu kanye nezakhiwo zemishini kungalawulwa ngokulungisa isilinganiso sokuqhuma (BUR - isilinganiso sobubanzi bebhamuza kuya kububanzi bokufa) kanye nesilinganiso sokudonsela phansi (DDR - isilinganiso sesivinini sokuthatha kuya kusivinini sokuphuma).

2. Inqubo Yokukhipha Amafilimu Abalingisi

Ukukhishwa kwefilimu ehlanganisiwe kungenye inqubo ebalulekile yokukhiqiza amafilimu e-polyolefin, afanelekela kakhulu ukukhiqiza amafilimu adinga izakhiwo zokukhanya eziphezulu (isb., ukucaca okuphezulu, ukukhanya okuphezulu) kanye nokufana okuhle kobukhulu. Kule nqubo, i-polymer ehlanganisiwe ikhishwa ngokuvundlile nge-T-die eyisicaba, yohlobo lwe-slot, yakha iwebhu ehlanganisiwe ehlanganisiwe. Le webhu idonswa ngokushesha ebusweni be-roll eyodwa noma ngaphezulu yesivinini esiphezulu, epholile ngaphakathi. Ukuncibilika kuqina ngokushesha lapho kuhlangana nobuso be-roll ebandayo. Amafilimu ehlanganisiwe ngokuvamile anezakhiwo ezinhle kakhulu zokukhanya, umuzwa othambile, kanye nokuvalwa okuhle kokushisa. Ukulawula okunembile phezu kwegebe lezindebe ze-die, izinga lokushisa le-roll ehlanganisiwe, kanye nesivinini sokujikeleza kuvumela ukulawulwa okunembile kobukhulu befilimu kanye nekhwalithi yobuso.

Izinselele Eziyi-6 Eziphezulu Zokukhipha Ifilimu ye-Polyolefin

Naphezu kokuvuthwa kobuchwepheshe bokukhipha, abakhiqizi bavame ukubhekana nochungechunge lobunzima bokucubungula ekukhiqizweni okusebenzayo kwamafilimu e-polyolefin, ikakhulukazi lapho belwela ukukhipha okuphezulu, ukusebenza kahle, ama-gauge amancane, kanye nalapho besebenzisa ama-resin amasha asebenza kahle kakhulu. Lezi zinkinga azithinti nje kuphela ukuzinza kokukhiqiza kodwa futhi zithinta ngqo ikhwalithi yokugcina yomkhiqizo kanye nezindleko. Izinselele ezibalulekile zifaka:

1. Ukuqhekeka Kwe-Melt (Sharkskin): Lokhu kungenye yeziphambeko ezivame kakhulu ekukhishweni kwefilimu ye-polyolefin. Ngokwe-macroscopic, kubonakala njengama-ripples ajikelezayo noma indawo engajwayelekile ebhodweni, noma ezimweni ezimbi kakhulu, ukuphambuka okusobala kakhulu. Ukuqhekeka kwe-Melt kwenzeka ikakhulukazi lapho izinga lokushefa kwe-polymer melt ephuma ku-die lidlula inani elibalulekile, okuholela ekunyakazeni okunamathelayo phakathi kodonga lwe-die kanye nokuqhekeka okukhulu, noma lapho ukucindezeleka kokwelulwa ekuphumeni kwe-die kudlula amandla okuncibilika. Lokhu kuphazamiseka kuphazamisa kakhulu izakhiwo zokukhanya zefilimu (ukucaca, ukukhanya), ukushelela kobuso, futhi kungalimaza nezakhiwo zayo zemishini nezesithiyo.

2. Ukwakheka Kwe-Die Drool/Die: Lokhu kubhekisela ekuqongeleleni kancane kancane kwemikhiqizo yokuwohloka kwe-polymer, izingxenyana zesisindo esiphansi sama-molecule, izithasiselo ezihlakazekile kahle (isb., ama-pigment, ama-antistatic agents, ama-slip agents), noma ama-gel avela ku-resin emaphethelweni ezindebe ze-die noma ngaphakathi kwe-die cavity. Lawa ma-deposit angaphuma ngesikhathi sokukhiqizwa, engcolisa ubuso befilimu futhi abangele amaphutha afana nama-gel, imicu, noma imihuzuko, ngaleyo ndlela kuthinte ukubukeka komkhiqizo kanye nekhwalithi. Ezimweni ezimbi kakhulu, ukwakheka kwe-die kungavimba ukuphuma kwe-die, okuholela ekushintsheni kwe-gauge, ukudabuka kwefilimu, futhi ekugcineni kuphoqe ukuvalwa kwemigqa yokukhiqiza ukuze kuhlanzwe i-die, okuholela ekulahlekelweni okukhulu ekusebenzeni kahle kokukhiqiza kanye nokuchitheka kwezinto zokusetshenziswa.

3. Ukucindezela Okuphezulu Kokukhipha kanye Nokuguquguquka: Ngaphansi kwezimo ezithile, ikakhulukazi lapho kucutshungulwa ama-resin ane-viscosity ephezulu noma kusetshenziswa izikhala ezincane ze-die, ingcindezi ngaphakathi kwesistimu ye-extrusion (ikakhulukazi ekhanda le-extruder kanye ne-die) ingaba phezulu kakhulu. Ingcindezi ephezulu ayikhulisi nje kuphela ukusetshenziswa kwamandla kodwa futhi ibeka engcupheni isikhathi eside semishini (isb., isikulufu, umgqomo, i-die) kanye nokuphepha. Ngaphezu kwalokho, ukuguquguquka okungazinzile kwengcindezi ye-extrusion kubangela ngqo ukushintshashintsha kokukhishwa kokuncibilika, okuholela ekujiyeni kwefilimu okungafani.

4. Umthamo Olinganiselwe: Ukuze kuvinjelwe noma kuncishiswe izinkinga ezifana nokuqhekeka kokuncibilika kanye nokwakheka kokufa, abakhiqizi bavame ukuphoqeleka ukunciphisa isivinini sesikulufo se-extruder, ngaleyo ndlela banciphise umkhiqizo womugqa wokukhiqiza. Lokhu kuthinta ngqo ukusebenza kahle kokukhiqiza kanye nezindleko zokukhiqiza ngeyunithi ngayinye yomkhiqizo, okwenza kube nzima ukuhlangabezana nezidingo zemakethe zamafilimu amakhulu, ashibhile.

5. Ubunzima Ekulawuleni Isilinganiso: Ukungazinzi ekugelezeni kokuncibilika, ukusatshalaliswa kwezinga lokushisa okungalingani kuyo yonke idayisi, kanye nokwakheka kwedayi konke kungafaka isandla ekushintsheni kobukhulu befilimu, kokubili ngokuphambeneyo nangokude. Lokhu kuthinta ukusebenza kwefilimu okulandelayo kanye nezici zokusetshenziswa kokugcina.

6. Ukushintsha Okunzima Kwe-Resin: Uma ushintsha phakathi kwezinhlobo ezahlukene noma amazinga ama-polyolefin resins, noma uma ushintsha ama-masterbatches ombala, izinto ezisele kusukela ekuqhutshweni kwangaphambilini zivame ukuba nzima ukuzisusa ngokuphelele ku-extruder bese zifa. Lokhu kuholela ekuhlanganisweni kwezinto ezindala nezintsha, ukukhiqiza izinto zokuguquka, ukwandisa izikhathi zokushintsha, kanye nokwandisa amazinga okulahla.

Lezi zinselele zokucubungula ezivamile zivimbela imizamo yabakhiqizi bamafilimu e-polyolefin yokuthuthukisa ikhwalithi yomkhiqizo kanye nokusebenza kahle kokukhiqiza, futhi zibeka izithiyo ekwamukelweni kwezinto ezintsha kanye namasu okucubungula athuthukile. Ngakho-ke, ukufuna izixazululo ezisebenzayo zokunqoba lezi zinselele kubalulekile ekuthuthukisweni okuqhubekayo nokunempilo kwemboni yonke yokukhipha amafilimu e-polyolefin.

Izixazululo zenqubo yokukhipha ifilimu ye-Polyolefin: Izinsiza Zokucubungula ze-Polymer (PPAs)

Izinsiza Zokucubungula Ama-polymer (ama-PPA) ziyizithasiselo ezisebenzayo ezinenani eliyinhloko ekuthuthukiseni ukuziphatha kwe-rheological kokuncibilika kwe-polymer ngesikhathi sokukhipha kanye nokushintsha ukusebenzisana kwazo nezindawo zemishini, ngaleyo ndlela kunqobe ubunzima bokucubungula obuningi kanye nokuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

1. Ama-PPA asekelwe ku-Fluoropolymer

Isakhiwo Nezimpawu Zamakhemikhali: Lawa njengamanje yiklasi lama-PPA asetshenziswa kakhulu, avuthiwe kwezobuchwepheshe, futhi asebenza kahle kakhulu. Ngokuvamile angama-homopolymer noma ama-copolymer asekelwe kuma-monomers e-fluoroolefin njenge-vinylidene fluoride (VDF), i-hexafluoropropylene (HFP), kanye ne-tetrafluoroethylene (TFE), kanti ama-fluoroelastomers ayiwona amele kakhulu. Amaketanga ama-molecule alawa ma-PPA acebile ngama-bond-energy aphezulu, ama-low-polarity CF bonds, anikeza izakhiwo ezihlukile ze-physicochemical: amandla aphansi kakhulu ebusweni (afana ne-polytetrafluoroethylene/Teflon®), ukuzinza okuhle kakhulu kokushisa, kanye nokungangeni kwamakhemikhali. Ngokubaluleke kakhulu, ama-PPA e-fluoropolymer ngokuvamile abonisa ukuhambisana okungekuhle nama-polyolefin matrices angewona ama-polar (njenge-PE, PP). Lokhu kungahambisani kuyisidingo esibalulekile sokufuduka kwawo okuphumelelayo ezindaweni zensimbi ze-die, lapho akha khona i-dynamic lubricating coating.

Imikhiqizo Emele: Imikhiqizo ehamba phambili emakethe yomhlaba wonke yama-PPA e-fluoropolymer ifaka uchungechunge lwe-Chemours' Viton™ FreeFlow™ kanye nochungechunge lwe-3M's Dynamar™, olunesabelo esikhulu semakethe. Ngaphezu kwalokho, amanye ama-grade e-fluoropolymer avela ku-Arkema (uchungechunge lwe-Kynar®) kanye ne-Solvay (Tecnoflon®) nawo asetshenziswa njenge, noma ayizingxenye ezibalulekile, ekwakhiweni kwe-PPA.

2. Izinsiza Zokucubungula Ezisekelwe ku-Silicone (ama-PPA)

Isakhiwo Samakhemikhali Nezimpawu: Izingxenye ezisebenzayo eziyinhloko kulesi sigaba sama-PPA yi-polysiloxanes, evame ukubizwa ngokuthi ama-silicone. Umgogodla we-polysiloxane uqukethe ama-athomu e-silicon ne-oxygen ashintshanayo (-Si-O-), anamaqembu e-organic (ngokuvamile i-methyl) anamathele kuma-athomu e-silicon. Lesi sakhiwo sama-molecule esiyingqayizivele sinikeza izinto ze-silicone ukucindezeleka okuphansi kakhulu kobuso, ukuzinza okuhle kokushisa, ukuguquguquka okuhle, kanye nezakhiwo ezinganamatheli ezintweni eziningi. Njenge-fluoropolymer PPAs, ama-PPA asekelwe ku-silicone asebenza ngokuthuthela ezindaweni zensimbi zemishini yokucubungula ukuze akhe ungqimba lokugcoba.

Izici Zokusebenza: Nakuba ama-PPA e-fluoropolymer elawula umkhakha wokukhipha ifilimu ye-polyolefin, ama-PPA asekelwe ku-silicone angabonisa izinzuzo ezihlukile noma adale imiphumela yokusebenzisana uma esetshenziswa ezimweni ezithile zokusetshenziswa noma ngokubambisana nezinhlelo ezithile ze-resin. Isibonelo, angacatshangelwa izinhlelo zokusebenza ezidinga ama-coefficients aphansi kakhulu okungqubuzana noma lapho izici ezithile zomphezulu zifunwa khona kumkhiqizo wokugcina.

Ukubhekana Nokuvinjelwa Kwe-Fluoropolymer Noma Izinselele Zokunikezwa Kwe-PTFE?

Xazulula Izinselele Zokukhipha Ifilimu zePolyolefin ngezixazululo ze-PPA zamahhala ze-PFAS-Izithasiselo ze-SILIKE's Fluorine Polymer

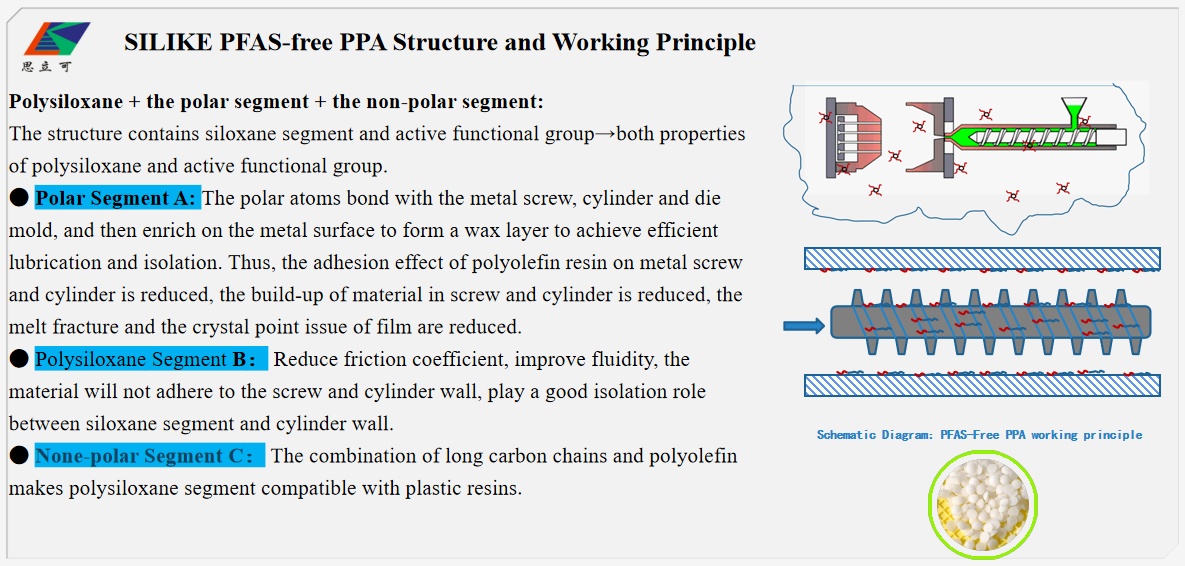

I-SILIKE isebenzisa indlela yokuthatha isinyathelo ngemikhiqizo yayo yochungechunge lwe-SILIMER, inikeza izinto ezintshaIzinsiza zokucubungula i-polymer ezingenayo i-PFAS (ama-PPA)). Lo mugqa womkhiqizo ophelele unama-PPA ahlanzekile angu-100% angenayo i-PFAS,Izithasiselo ze-polymer ze-PPA ezingena-fluorine, futhiAma-masterbatch e-PPA angenayo i-PFAS futhi angenayo i-fluorine.Ngoukuqeda isidingo sezithasiselo ze-fluorine, lokhu kucubungula kusiza kakhulu ekuthuthukiseni inqubo yokukhiqiza ye-LLDPE, LDPE, HDPE, mLLDPE, PP, kanye nezinqubo ezahlukahlukene zokukhipha ifilimu ye-polyolefin. Zihambisana nemithethonqubo yakamuva yezemvelo ngenkathi futhi zithuthukisa ukusebenza kahle kokukhiqiza, zinciphisa isikhathi sokungasebenzi, futhi zithuthukisa ikhwalithi yomkhiqizo iyonke. Ama-PPA angenayo i-PFAS e-SILIKE aletha izinzuzo kumkhiqizo wokugcina, okuhlanganisa ukususwa kokuqhekeka kokuncibilika (isikhumba soshaka), ukushelela okuthuthukisiwe, kanye nekhwalithi ephezulu yobuso.

Uma ubhekene nobunzima bokuvinjelwa kwe-fluoropolymer noma ukuntuleka kwe-PTFE ezinqubweni zakho zokukhipha i-polymer, i-SILIKE inikeza.ezinye izindlela ezingasetshenziswa esikhundleni se-fluoropolymer PPAs/PTFE, Izithasiselo ezingenayo i-PFAS zokukhiqiza amafilimuezenzelwe ukuhlangabezana nezidingo zakho, ngaphandle kokushintsha kwenqubo okudingekayo.

Isikhathi sokuthunyelwe: Meyi-15-2025