I-Color Masterbatch uhlobo olusha lwe-ejenti ekhethekile yokufaka imibala yezinto ze-polymer, eyaziwa nangokuthi ukulungiswa kwe-pigment. Iqukethe izinto ezintathu eziyisisekelo: i-pigment noma idayi, i-carrier kanye nezithasiselo, futhi iyi-aggregate etholakala ngokunamathisela ngokulinganayo inani elingavamile le-pigment noma idayi ku-resin. Izinsiza zokucubungula ziyadingeka ukuqinisekisa ukuthi inani elikhulu le-pigment lingasakazwa ngokulinganayo, ukuvimbela ukuhlangana, nokugwema izinkinga ezifana nokuqhekeka kokuncibilika kanye nokunciphisa ukwakheka kwe-die ngesikhathi sokucubungula.

Kunezithasiselo eziningi kangaka emakethe ezingasetshenziselwa i-color masterbatch, hlobo luni lwezithasiselo olungaxazulula kangcono lezi zinkinga ezingenhla?

I-SILIMERuchungechungei-silicone hyperdispersant, Khuthaza ukusabalala okusebenzayo nokulinganayo kwama-powder ombala

Inkinga 1: Amamaki okugeleza kokukhipha i-Masterbatch enemibala, ubuso obubi bomkhiqizo enqubweni yokucubungula i-masterbatch.

Inkinga 2: I-masterbatch ejikelezayo kulula ukuyiphula, ayisebenzi kahle, futhi inani lokuhlunga alilihle.

Ukuhlaziywa kwesizathu: Isizathu esiyinhloko ukuthi usayizi wezinhlayiya zempuphu yombala mkhulu kakhulu noma impuphu yombala ayihlakazeki ngokulinganayo futhi ihlangana ngendlela ethile ngesikhathi sokucubungula.

Isixazululo: I-SILIKE SILIMER series silicone hyperdispersantuhlobo lomkhiqizo we-polysiloxane we-copolymer oguquliwe, ongathuthukisa ukuhambisana phakathi kompushana wombala kanye ne-substrate ye-resin, ukhuthaze ukusabalala okusebenzayo nokulinganayo kompushana wombala futhi uwugcine uzinzile, ngisho ne-chromaticity, uthuthukise amandla okufaka umbala we-pigment, uthuthukise ukugeleza kohlelo, uthuthukise ukusebenza kokucubungula, futhi okwamanje, unganciphisa i-coefficient yokungqubuzana kobuso ngokusebenzisa izici zamandla aphansi okujikeleza kwe-silicon chain, ukuze uthuthukise ukushelela kobuso bemikhiqizo. Futhi ungaqinisekisa ukukhiqizwa okubushelelezi kokuphotha kwe-extrusion.

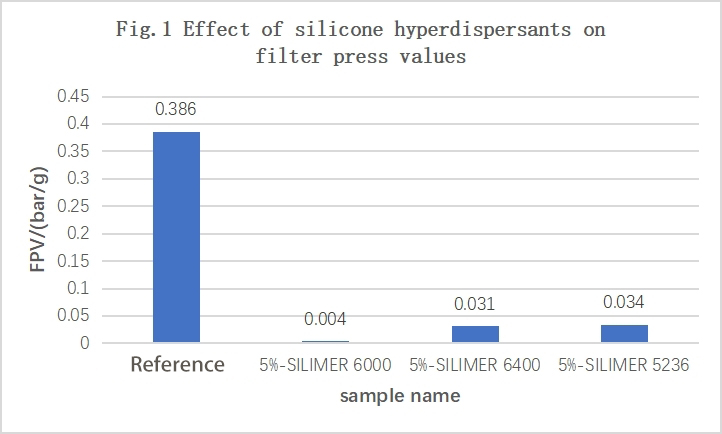

Njengoba kuboniswe ku-Fig. 1, ngaphansi kwezinga lokushisa lokuhlola: 235℃; isampula iyonke: 1000g; isisindo se-pigment: 80g; ukwengeza kwe-masterbatch: 20%; i-substrate PP: 80%; imininingwane yesihlungi: izimo zokuhlola ze-mesh eziyi-1000, kungabonakala ukuthi ngemuva kokufakwa kwe-SILIKE silicone hyperdispersantI-SILIMER6000, I-SILIMER6400, I-SILIMER5236ku-masterbatch, inani lokuhlunga ingcindezi lincishisiwe kakhulu, okubonisa ukuthiI-SILIKE silicone hyperdispersantithuthukisa ngempumelelo isenzakalo sokuhlanganisana kwempuphu, futhi ithuthukise nokuhlakazeka kwempuphu. I-dispersant ingasetshenziswa ukuthuthukisa ukuhlakazeka kwempuphu.

Usizo lwe-SILIKE PFAS lwe-PPA Polymer Process Aid, Susa ukuqhekeka kokuncibilika bese wandisa imijikelezo yokuhlanza imishini

Inkinga 3: Isikhunta se-masterbatch extrusion sombala siqoqa izinto, futhi umjikelezo wokuhlanza imishini umfushane.

Ukuhlaziywa kwesizathu: Ngenxa yokungahambisani kahle kombala wempuphu kanye nezinto eziyisisekelo, ingxenye yombala wempuphu kulula ukuyihlanganisa ngemva kokuxuba, kukhona umehluko phakathi kokugeleza kombala wempuphu kanye ne-resin kanye ne-viscosity yokuncibilika okukhulu enkambisweni yokukhipha, ngesikhathi esifanayo, kukhona umphumela oqinile phakathi kwemishini yokukhipha insimbi kanye nohlelo lwe-resin, okuholela ekutheni izinto ezifile emzimbeni wegumbi kanye nokukhishwa komlomo we-die, umbala wempuphu kanye ne-thermoplastic resin kuyasuswa ngesikhathi senqubo yokukhipha okuholela ekuqongeleleni komlomo kanye ne-die kwezinto, futhi indima phakathi kokuncibilika kwe-resin kanye nemishini yensimbi idinga ukuncishiswa ukuze kugwenywe isimo esinjalo. Kuyadingeka ukwenza buthaka ukusebenzisana phakathi kokuncibilika kwe-resin kanye nemishini yensimbi ukuze kugwenywe lesi simo.

Inkinga 4: Ukuqhekeka okuncibilikayo ngesikhathi sokukhipha ngesivinini esikhulu, ukuhlukaniswa kombala wempuphu kanye nokuna kwemvula.

Ukuhlaziywa kwesizathu: Njengoba izinga lokugunda elibalulekile lezinto ngokwazo lincane uma uhlelo lwempuphu yombala lukhishwa ngesivinini esikhulu, kuzoba nezinkinga ezinkulu zokuqhekeka kokuncibilika kanye nokwakheka kokufa uma lukhishwa ngesivinini esikhulu, okuzobangela ukuhlukana kanye nokuna kwempuphu yombala. I-Fluoropolymer iyi-polymer ene-viscosity ephezulu ohlelweni lwempuphu yombala enqubweni yokufuduka kwangaphandle. Ikhono lokuthuthuka livamile.

Isixazululo: Izinsiza zokucubungula i-PPA ezingenayo i-SILIKE PFASiwumkhiqizo we-polysiloxane masterbatch oguquliwe ngokwe-organically ohlanganisa izingxenye ze-polysiloxane chain namaqembu e-polar, ohlanganisa ukusebenza okuhle kakhulu kokubili, futhi uthuthukise isakhiwo ngesikhathi esisodwa. I-PPA engenayo i-Fluorine isebenzisa amaqembu aguquliwe angahlanganiswa kakhulu nezikulufo zensimbi ukuze athathe indawo yendima ye-fluorine ku-PPA equkethe i-fluorine, bese isebenzisa izici zamandla aphansi ebusweni be-silicone ukwakha ifilimu ye-silicone ebusweni bemishini yensimbi ukuze kufezwe umphumela wokuhlukaniswa, okwandisa ngempumelelo umjikelezo wokuhlanza wemishini ukuze kufinyezwe isikhathi sokungasebenzi, kuqedwe ukuqhekeka kokuncibilika, kuncishiswe ukwakheka kwe-die, futhi kuthuthukiswe indima yekhwalithi yobuso. Ngaphezu kwalokho, inezici zokuvikela imvelo okungeyona i-PFAS, kuncishiswe i-extrusion torque, kuthuthukiswe uketshezi lokucubungula nokunye.

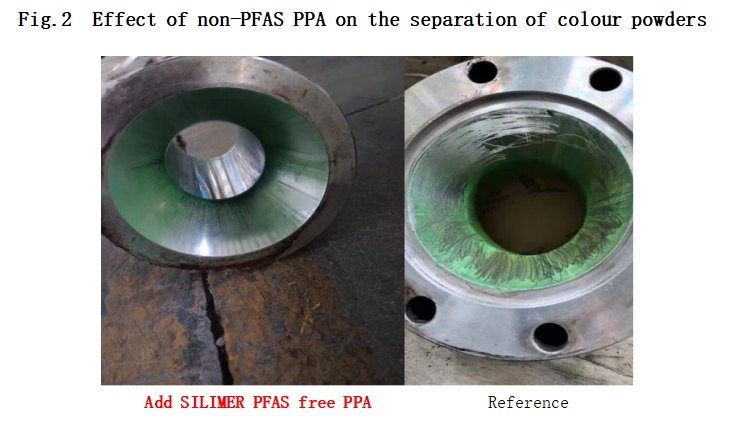

Njengoba kuboniswe kuMfanekiso 2, ngemva kokuba ikhasimende lisebenziseIzinsiza Zokucubungula I-Polymer Ezingenayo i-SILIKE PFAS, ngesikhathi esifanayo sokucubungula, umbala wempuphu onamathela odongeni lwangaphakathi lomshini uthuthukisiwe kakhulu.

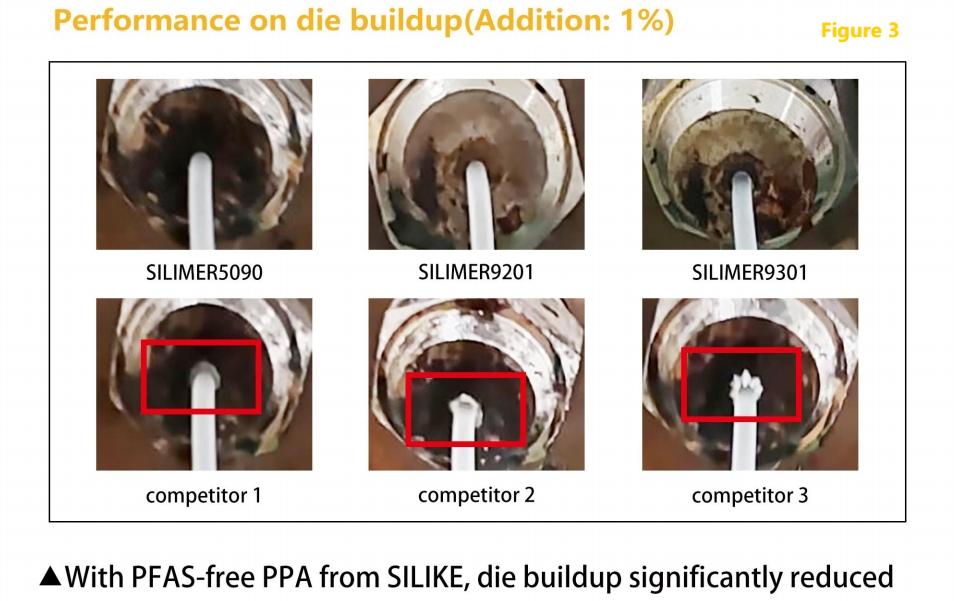

Njengoba kuboniswe ku-Fig. 3, ngaphansi kwesimo sokukhipha esingaphansi kwemizuzu engama-30 kanye nenani elifanayo lokwengeza, ukuthuthukiswa kwe-SILIKE non-PFAS PPA ekubunjweni kwe-die kungcono kakhulu kunokwe-PPA ene-fluorine.

Abakhiqizi be-Color Masterbatch, uma uhlangabezana nanoma yiziphi izinkinga noma izinkinga ngesikhathi sokucubungula i-masterbatch, sicela uxhumane nathi, i-SILIKE ingakunikeza izixazululo zokucubungula ezenziwe ngokwezifiso.

I-Chengdu SILIKE Technology Co., Ltd, i-China ehamba phambiliIsengezo se-SiliconeUmhlinzeki wepulasitiki eguquliwe, unikeza izixazululo ezintsha zokuthuthukisa ukusebenza kanye nokusebenza kwezinto zepulasitiki. Siyakwamukela ukuxhumana nathi, i-SILIKE izokunikeza izixazululo zokucubungula ipulasitiki ezisebenza kahle.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

iwebhusayithi:www.siliketech.comukuze ufunde kabanzi.

Isikhathi sokuthunyelwe: Okthoba-16-2024