Impuphu emhlophe ethela esikhwameni sokupakisha ukudla ingenxa yokuthi i-slip agent (i-oleic acid amide, i-erucic acid amide) esetshenziswa umenzi wefilimu ngokwayo iyathela, futhi indlela esebenza ngayo i-amide slip agent yendabuko ukuthi isithako esisebenzayo sithuthela ebusweni befilimu, sakhe ungqimba olulodwa lokugcoba lwama-molecule futhi sinciphise i-friction coefficient yobuso befilimu. Kodwa-ke, ngenxa yesisindo esincane sama-molecule se-amide slip agent, kulula ukuyithela noma ukuyithela, ngakho-ke impuphu kulula ukuyihlala ku-composite roller ngesikhathi senqubo yokuhlanganisa ifilimu, futhi impuphu ku-raber roller izonamathela ngesikhathi sokucubungula ifilimu, okuholela kumpuphu omhlophe osobala kumkhiqizo wokugcina.

Ukuze kuxazululwe inkinga yokunisela kalula kwama-amide slip agents endabuko, i-SILIKE ithuthukise umkhiqizo we-co-polysiloxane oguquliwe oqukethe amaqembu asebenzayo asebenzayo e-organic -I-ejenti yokushelela engaqhakazi yochungechunge lwe-SILIMERyefilimu yepulasitiki. Isimiso sokusebenza salo mkhiqizo ukuthi amaqembu asebenzayo asebenzayo ku-long carbon chain angakha isibopho esingokwenyama noma samakhemikhali ne-base resin, esebenza njenge-anchor ukuze kufezwe ukufuduka okulula ngaphandle kwemvula. Izingxenye ze-polysiloxane chain ebusweni zinikeza umphumela wokushelela. Amabanga anconyiwe:SILIMER5064, I-SILIMER5064MB1,I-SILIMER5064MB2, I-SILIMER5065HB…

1.Izinzuzo ngeI-SILIMER Series Non-Precipitation Slip Agent Masterbatch

- Inikeza ukusebenza okuhlala isikhathi eside kokushelela ngokuhamba kwesikhathi nangaphansi kwezimo zokushisa okuphezulu

- Nikeza i-coefficient ezinzile nephansi yokungqubuzana, i-anti-blocking enhle, kanye nokushelela okungcono komkhiqizo wokugcina.

- Akukuthinti ukuphrinta, ukuvala ukushisa, ukuhlanganiswa, ukucaca, noma umswakama

- Iqeda izinkinga zempuphu, iphephile futhi ayinaphunga

- Kusetshenziswa kabanzi kumafilimu e-BOPP/CPP/PE/PP……

2.Idatha ethile yokuhlola ukusebenza efanele

- Ukunciphisa ngempumelelo i-friction coefficient, akuthintiinkungukanye nokudluliselwa

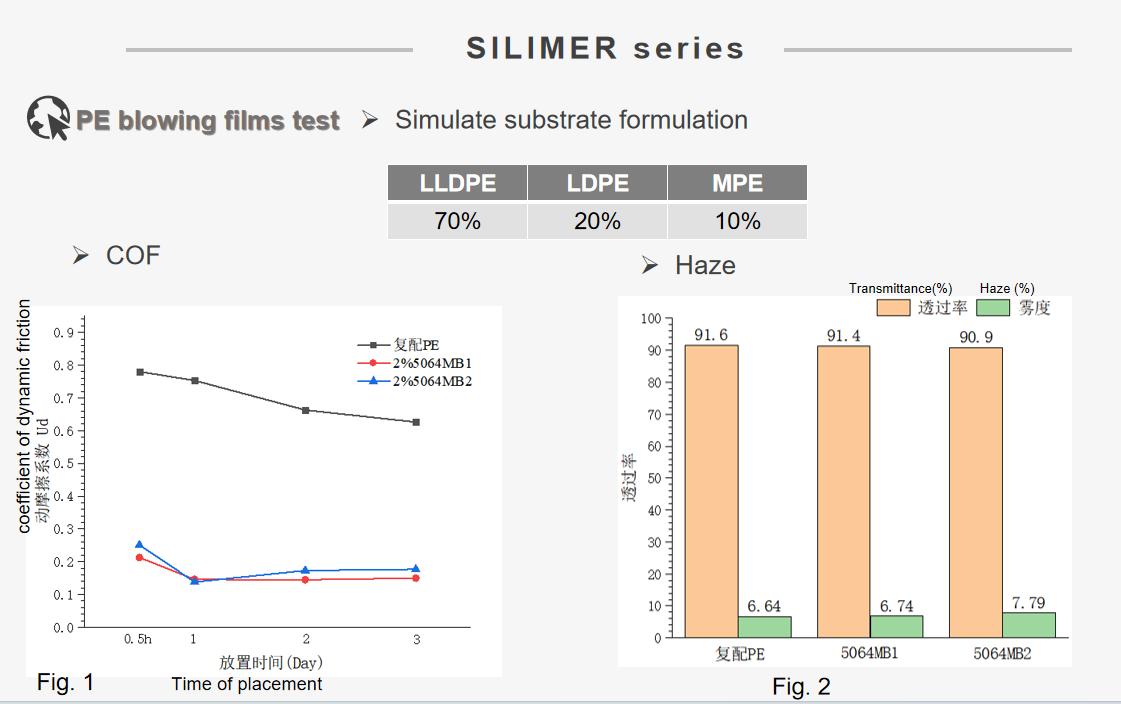

Ifomula ye-substrate elingisiwe: 70%LLDPE, 20%LDPE, 10% metallocene PE

Njengoba kuboniswe kuMfanekiso 1, i-coefficient yokungqubuzana kwefilimu ngemva kokwengeza u-2%I-SILIMER 5064MB1kanye no-2%I-SILIMER 5064MB2kwehliswe kakhulu uma kuqhathaniswa ne-PE ehlanganisiwe. Ngaphezu kwalokho, futhi njengoba kuboniswe kuMfanekiso 2, ukwengezwa kweI-SILIMER 5064MB1futhiI-SILIMER 5064MB2akuzange kuthinte ubumnyama kanye nokudluliswa kwefilimu.

- I-coefficient yokungqubuzana izinzile

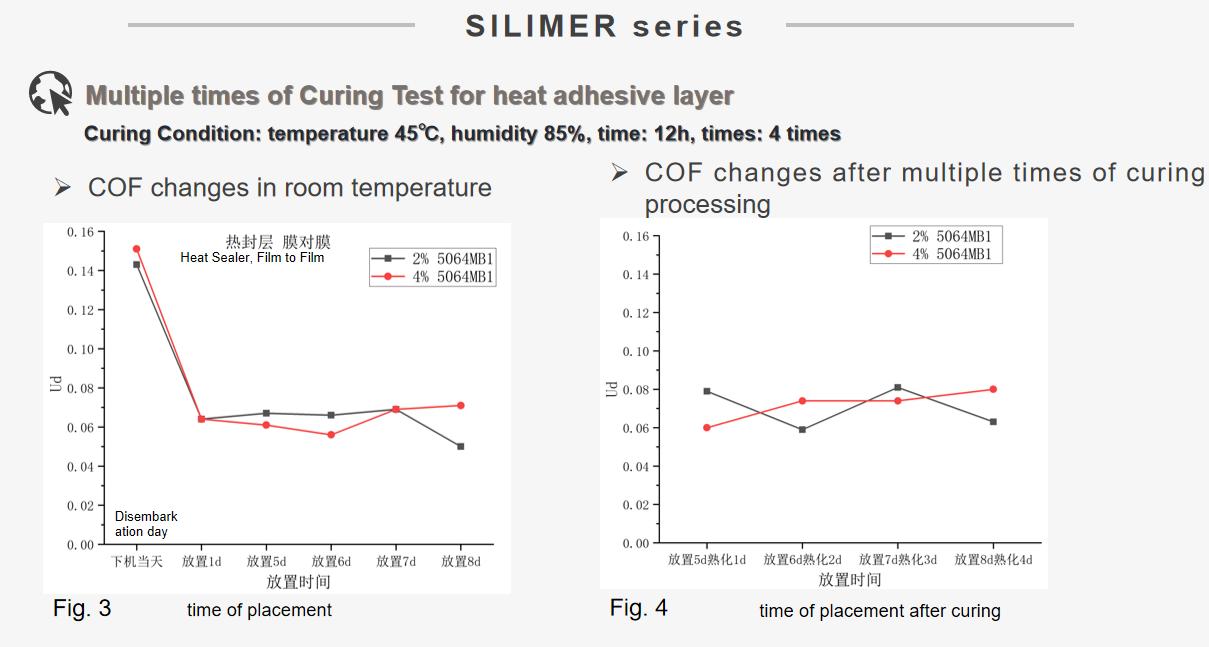

Izimo zokupholisa: izinga lokushisa 45℃, umswakama 85%, isikhathi 12h, izikhathi ezi-4

Njengoba kuboniswe ku-FIG. 3 kanye no-FIG. 4, kungabonakala ukuthi i-coefficient yokungqubuzana kwefilimu ngemva kokwengeza u-2%I-SILIMER 5064MB1kanye no-4%I-SILIMER 5064MB1ihlala inenani elizinzile ngemva kokwelashwa kaningi.

- Ubuso befilimu abunamanzi futhi abuthinti ikhwalithi yemishini kanye nomkhiqizo wokugcina

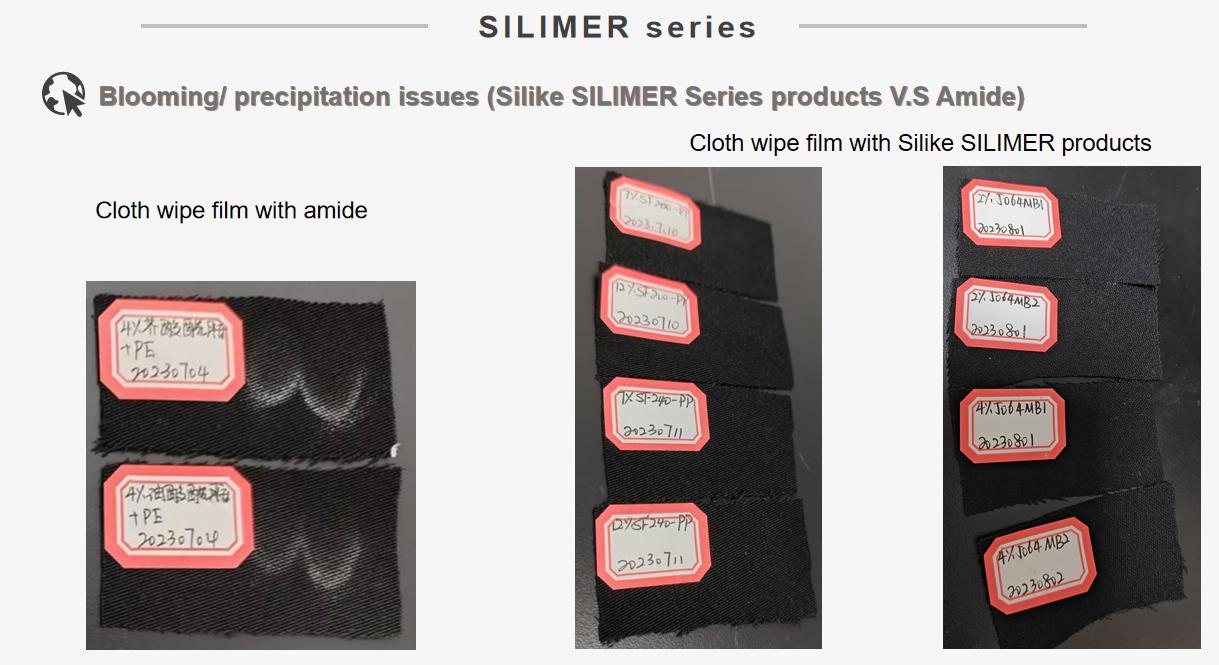

Njengoba kuboniswe esithombeni esingezansi, sebenzisa indwangu emnyama ukusula ubuso befilimu nge-amide kanyeUmkhiqizo we-SILIMERKungabonakala ukuthi uma kuqhathaniswa nokusetshenziswa kwezithasiselo ze-amide, uchungechunge lwe-SILIMER alunawo umswakama futhi alunawo umpuphu obangela ukukhukhumala.

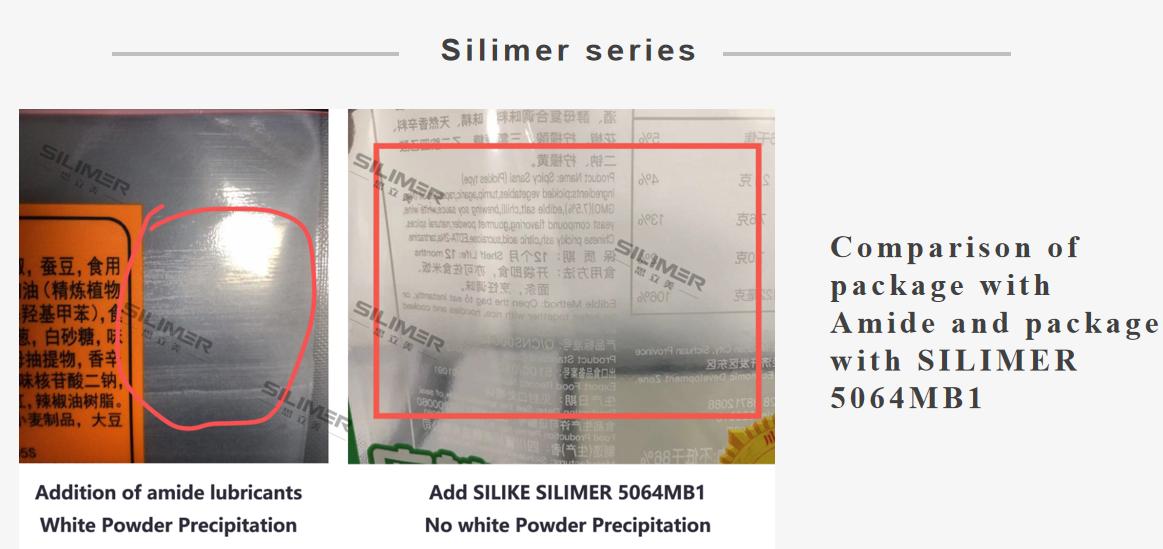

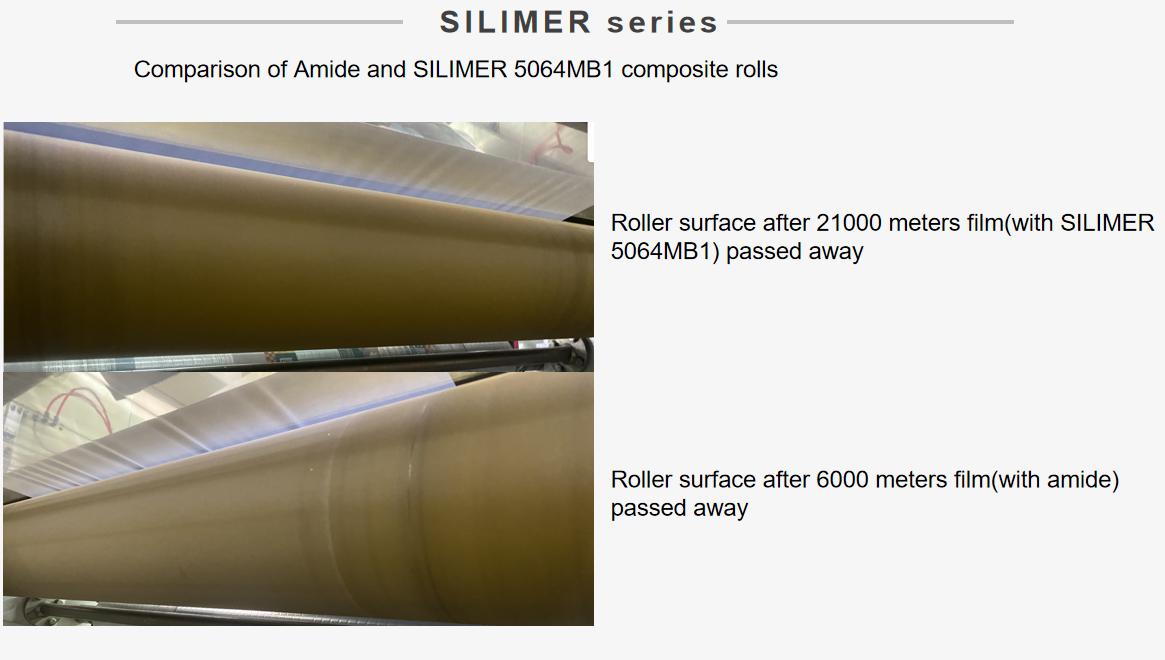

- Xazulula inkinga yempuphu emhlophe ku-composite roller kanye nesikhwama sokugcina somkhiqizo

Njengoba kuboniswe esithombeni esingezansi, ngemva kokuba i-composite roller idlule amamitha angu-6000 efilimu ene-erucic acid amide, kuba nokuqongelela okusobala kwempuphu emhlophe, futhi kukhona nempuphu emhlophe esobala esikhwameni somkhiqizo wokugcina; Kodwa-ke, isetshenziswa neUchungechunge lwe-SILIMERSingabona ukuthi i-composite roller idlule nini amamitha angu-21000, futhi isikhwama sokugcina somkhiqizo sasihlanzekile futhi sisha.

3. Amandla kaI-SILIKESI-ILIMERuchungechungeukushelela okuhlala njalo okungafudukiOkungeziwe Kokupakisha Okuguquguqukayo.

Shintsha Ukuphepha Kwakho Kokupakisha Ukudla! Ukhathele Ukuna kweMpuphu Emhlophe Ezikhwameni Zakho Zokupakisha Ezihlanganisiwe noma kwamanye amafilimu? Ulungele Ushintsho?Uchungechunge lwe-SILIKE SILIMERIsithasiselo Sokushelela Esihlala Njalo Esingafuduki Sokupakisha Okuguquguqukayo,i-ejenti yokushelela engaqhakazi, i-masterbatch ye-agent yokushelela engeyona imvula yefilimu yepulasitiki, iqeda izinkinga zempuphu, iqinisekisa isipiliyoni sokupakisha esingenaphutha nesihlanzekile. Xhumana nathi manje! Ake siguqule isipiliyoni sakho sokupakisha ndawonye!

Silapha ukuzokwakha izixazululo ezenzelwe wena!I-masterbatch ye-SILIKE SILIMER yochungechunge lwe-non-precipitation slip agentIfaneleka ezinhlelweni ezahlukene zepulasitiki, ingagcini nje kumafilimu okupakisha (ifilimu ye-BOPP, CPP, BOPET, EVA, TPU, LDPE, kanye ne-LLDPE.) futhi iletha izixazululo zokushelela ezizinzile nezihlala njalo zamashidi neminye imikhiqizo ye-polymer lapho kudingeka khona ukushelela kanye nezakhiwo zomphezulu ezithuthukisiwe.

Isikhathi sokuthunyelwe: Jan-19-2024