Amafilimu e-Thermoplastic Polyurethane (TPU) aziwa ngokuguquguquka kwawo okumangalisayo, ukuqina, kanye nezici zokusebenza okuphezulu, okwenza kube ukukhetha okuthandwayo kuzo zonke izimboni ezifana nezimoto, ezokwelapha, imfashini, kanye ne-electronics yabathengi. Ngenkathi amafilimu ajwayelekile e-TPU ehlonishwa ngokumelana kwawo nokuguguleka kanye nokuqina kwamakhemikhali, amafilimu e-TPU angama-matte athola ukuthambekela okukhulu ngenxa yokubukeka kwawo okuhle, ukukhanya okuncishisiwe, kanye nezindawo ezingamelani neminwe.

Kodwa-ke, ukuthola ukuqeda okuqinile nokusezingeni eliphezulu kwe-matte kumafilimu e-TPU kungaba yinselele. Izinkinga ezifana nokuthungwa okungalingani, ukusabalala kokukhanya okungekuhle, kanye nokukhubazeka kobuso kuvame ukuhlupha abakhiqizi. Lesi sihloko sihlola izindlela zokulungiselela eziqinisekisiwe zamafilimu e-TPU aqinile, sibhekana nezinselele ezibalulekile futhi sinikeze izixazululo ezisebenzayo ukukusiza ukhiqize imikhiqizo engenaphutha.

Izindlela Zokulungiselela Ifilimu E-Matte TPU

1. Ukukhethwa Kwe-Resin Nezithasiselo: Isisekelo Samafilimu E-Matte TPU

Uhambo lokudala amafilimu e-TPU acwebezelayo asezingeni eliphezulu luqala ngokukhetha izinto ezifanele.

1.1 I-TPU Resin

Ukukhetha i-TPU resin efanele kubalulekile. Izinto ezibalulekile okufanele uzicabangele zifaka:

Ubulukhuni: Ama-resin aqinile aphakathi nendawo kuya kwaqinile alungele ukugcina ubuqotho bomphezulu ngenkathi eqinisekisa ukuguquguquka.

Ukunwebeka: Ukunwebeka okuphezulu kubalulekile ekusetshenzisweni okudinga ukugoba noma ukwelula, njengengaphakathi lezimoto noma izicathulo.

Ukuhambisana Kokucubungula: Qinisekisa ukuthi i-resin iyahambisana nendlela yakho yokucubungula oyikhethile (ukukhipha, ukucubungula, njll.).

Indlela ephumelela kakhulu futhi esetshenziswa kabanzi yokukhiqiza ifilimu ye-TPU engama-matte ukuhlanganisa i-TPU nezithasiselo ezithile ezinciphisa ukucwebezela futhi ziyinike ukuqeda okungama-matte. Lezi zithasiselo, ezivame ukubizwa ngokuthiama-ejenti okumboza ,izibambo zomatilasinomaisithasiselo se-TPU esingacwebezeli,zifakwa ku-TPU ngesikhathi senqubo yokuhlanganisa.izithasiselo ze-matt flattingukusebenza ngokuphazamisa ubuso obubushelelezi befilimu, okuholela ekuhlakazekeni kokukhanya okuholela ekubukekeni okungabonakali. Izinhlobo ezivamile zama-matting agents zifaka:

Ama-Matting Agents Asekelwe ku-Silica: Lezi zinhlayiya ezincane ze-silica ziphazamisa ukushelela kwendawo, zidale ukuthungwa okuqinile okuhlakaza izibani.

Ama-Polymeric Matting Agents: Lawa ma-ejenti ngokuvamile afana kakhulu futhi anikeza ukusabalala okungcono ku-TPU matrix.

I-Calcium Carbonate: Nakuba ingasetshenziswa kakhulu njenge-silica noma ama-polymeric agents, ingasetshenziswa kwezinye izindlela zokuqeda okungabonakali.

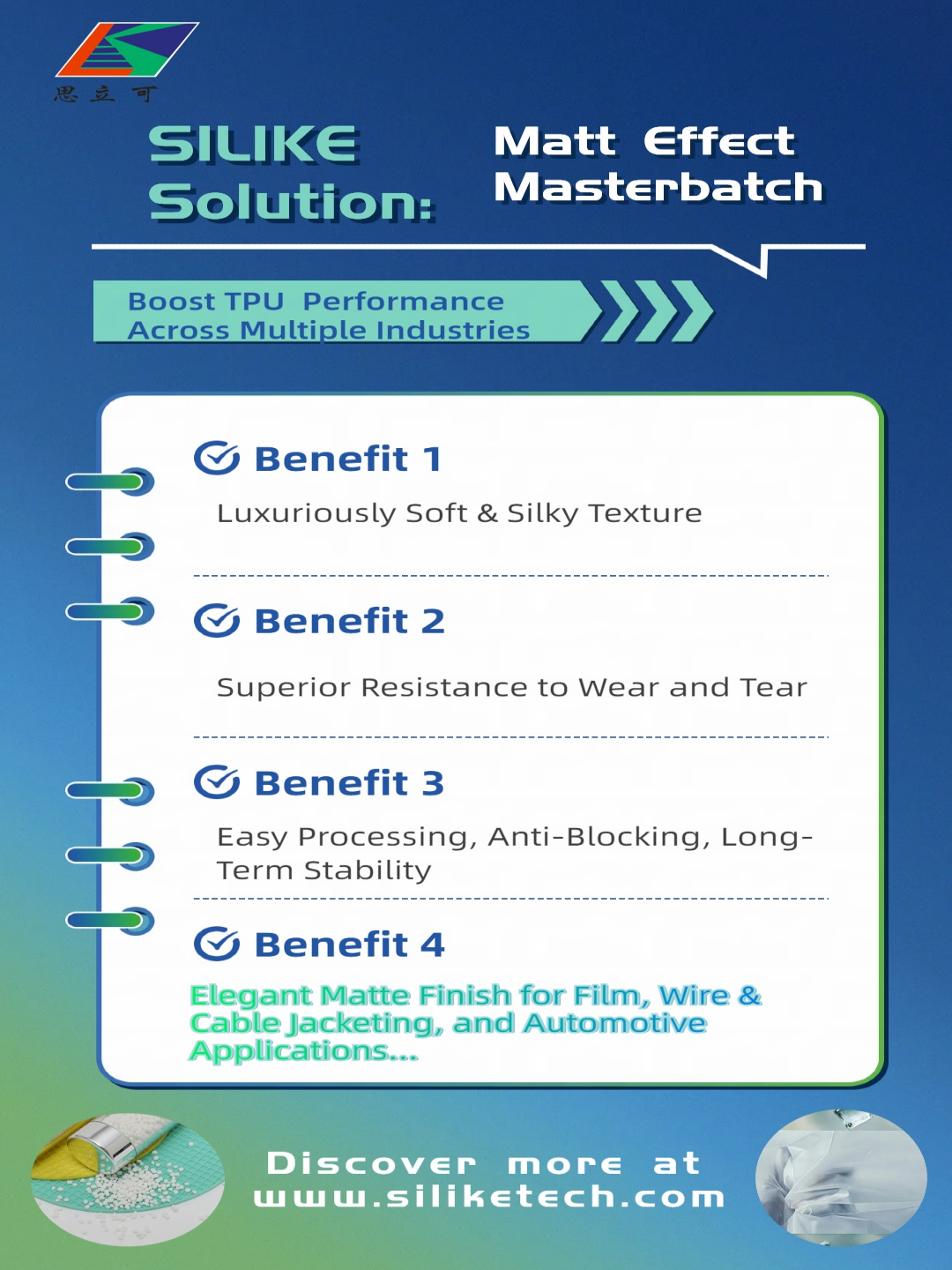

Icebiso Lobungcweti: Thuthukisa Ukuqina Nokukhanga Okungacwasi: Izixazululo ze-SILIKE's TPU based Masterbatch

I-Matt Effect Masterbatchiyi-Matting Agent entsha ethuthukiswe yi-SILIKE, isebenzisa i-thermoplastic polyurethane (TPU) njengesithwali sayo. Iyahambisana ne-TPU esekelwe ku-polyester kanye ne-polyether, le-matting agent yenzelwe ukuthuthukisa ukubukeka oku-matte, ukuthinta kwendawo, ukuqina, kanye nezakhiwo zokulwa nokuvimba zamafilimu e-TPU kanye nemikhiqizo yawo yokugcina.

Okuvelele kakhuluI-SILIKE's Polyester TPU-based kanye ne-Polyether TPU-based Matt Effect Masterbatch lilula kakhulu—ingafakwa ngqo ngesikhathi sokucubungula, isuse isidingo se-granulation, futhi iqinisekise ukuthi akukho bungozi bemvula ngisho noma isetshenziswa isikhathi eside.

Ilungele izinhlelo zokusebenza ezidinga ukuqedwa kwe-matte ephezulu, njengefilimu ze-TPU ezisetshenziswa ekupakisheni, ezimotweni, ezicathulweni, kumadivayisi ezokwelapha, kanye nasezintweni zikagesi zabathengi.

Ikakhulukazi,I-Matt Effect Masterbatch 3235ilungele ukudala isiphetho se-TPU esi-matte se-polyester esihle kakhulu sezinhlelo zokupakisha.

1.3 Izithasiselo Ezengeziwe

Ukuze uthuthukise ukusebenza, cabanga ngokufaka:

Izinto Ezivimbela Ukuvimba Zivimbela amafilimu ukuthi anganamatheli ndawonye ngesikhathi sokugcina.

Iziqinisi ze-UV: Zivikela ekuwohlokeni kwe-UV, zilungele ukusetshenziswa ngaphandle.

Izinto Zokushelela: Thuthukisa izakhiwo zokushelela ebusweni ukuze kube lula ukuziphatha.

2. Inqubo Yokukhipha: Ukunemba Kuyisihluthulelo

Ukukhipha amafilimu kuyindlela evame kakhulu yokukhiqiza amafilimu e-TPU. Ukuze uthole ukuqeda okumsulwa okumsulwa:

2.1 Isikhiphi Sesikulufa Esiphindwe Kabili

I-extruder enama-screw amabili iqinisekisa ukuxubana okungcono kanye nokuhlakazeka kwama-matting agents, okuholela ekubukekeni okufanayo kwe-matte.

2.2 Ukulawula Izinga Lokushisa

Gcina izinga lokushisa lilawulwa kahle ukuze ugweme amaphutha aphezulu njengamabhamuza, imicu, noma ukukhanya okungalingani.

2.3 Umklamo Wokufa

Sebenzisa idayi eliyisicaba elinokuphela kobuso obungacwebezeli noma ufake i-textured chill roll ukuze unikeze ukuthungwa kobuso obufunayo.

3. Amasu Okwelapha Okungaphezulu: Ukuthuthukisa Umphumela Omangele

Ukwelashwa kwendawo kungathuthukisa kakhulu ukuqeda kwe-matte futhi kuthuthukise ukusebenza:

3.1 Ukugqoka

Faka isembozo esingacwebezeli usebenzisa amasu okufaka i-roll noma i-spray ukuze uthuthukise ukuthungwa kwendawo ngaphandle kokushintsha ukwakheka kwe-TPU.

3.2 Ukudweba nge-embossing

Dlulisa ifilimu kuma-roller embossing anokuthungwa okungacwebezeli ukuze udale iphethini ephakanyisiwe yokuqeda okufanayo.

3.3 Ukuqopha Amakhemikhali

Sebenzisa ukwelashwa kwamakhemikhali okuthambile ukuze ushintshe ubulukhuni bomphezulu, ufeze ukuthungwa okufana nokungacwebezeli ukuze kusetshenziswe ngokunemba okuphezulu.

4. Inqubo Yefilimu Eqhumayo vs. Ifilimu Yabalingisi: Ukukhetha Indlela Efanele

Ukukhetha phakathi kwezinqubo zefilimu eziqhumayo kanye nefilimu eqoshiwe kuncike ezicini zefilimu ozifunayo:

4.1 Inqubo Yefilimu Eqhumayo

Ilungele amafilimu amakhulu, inqubo yefilimu evuvukile isebenzisa ukupholisa komoya ukuze kufezwe ukuqeda okungokwemvelo oku-matte.

4.2 Inqubo Yamafilimu Abalingisi

Kungcono kakhulu kumafilimu amancane, inqubo yamafilimu abalingisi isebenzisa i-textured chill roll ukudala ukuqeda okuqinile nokusezingeni eliphezulu.

5. Amasu Okucubungula Ngemva Kokucubungula: Ukufeza Ukuqeda

Ukucubungula ngemuva kokucubungula kungathuthukisa umphumela we-matte futhi kuthuthukise ukusebenza kwefilimu:

5.1 Ukuhlelwa Kwekhalenda

Dlulisa ifilimu kuma-calendaring rollers ukuze ulungise ukuthungwa kanye nobukhulu bomphezulu, uqinisekise ukuthi ukuqeda kufana kakhulu.

5.2 Ukuvikela

Bopha ifilimu ye-TPU engama-matte nezinye izinto ukuze uthuthukise amandla, ukuqina, noma izakhiwo zokuvimbela ngenkathi ulondoloza ukubukeka okungama-matte.

5.3 Ukusikwa Komphezulu

Sebenzisa ukuguguleka komshini ukuze uthuthukise ukuthungwa okungacwebezeli, udale ukuqeda okufanako kobuso ukuze kusetshenziswe kahle kakhulu.

Umhlahlandlela Wamafilimu e-Matte TPU: I-Matt Effect Masterbatch ka-SILIKE Iyaletha

I-SILIKE'sI-Matt Effect Masterbatchinikeza ikhambi elithembekile nelisebenzayo le-ukukhiqiza amafilimu e-TPU acwebezelayo asezingeni eliphezuluNjengoba kulula ukuyihlanganisa ngesikhathi sokucubungula kanye nokuzinza kwesikhathi eside, kuyisinqumo esifanele sabakhiqizi abafuna ukuphakamisa imikhiqizo yabo.

Ulwa ne-TPU Film Gloss? Noma, usukulungele ukufeza ama-Premium Matte Finishes ekukhiqizweni kwefilimu yakho ye-TPU?

Xhumana ne-SILIKE—iumenzi we-Matte Effect Masterbatch ochwepheshe— ukuze ufunde kabanzi ngezinto ezintshaIzixazululo ze-TPU Matt Effect Masterbatchfuthi ucele isampula yezithasiselo zethu ze-Anti-blocking Matte Effect!

Ucingo: +86-28-83625089,Email: amy.wang@silike.cn, Iwebhusayithi: www.siliketech.com

Isikhathi sokuthunyelwe: Mashi-05-2025