Izinto zokwakha zefilimu yesikhwama sezingubo zepulasitiki zifaka phakathi okulandelayo, futhi izinzuzo kanye nobuthakathaka bazo yilezi ezilandelayo:

1.PE (i-polyethylene):

Izinzuzo: ukuqina okuhle, ukungesabi ukudabuka, ukumelana nokucindezelwa, amandla okuthwala, ukumelana nokuguguleka, akulula ukuphula, kunempilo futhi kuqinisekisiwe, ukudla kuyatholakala, ukuvala kahle.

Amaphutha: Ukucaca okuphansi, inkungu ephezulu, intengo ephezulu.

2. I-PP (i-Polypropylene):

Izinzuzo: ukucaca okuphezulu, ukumelana nomswakama ovaliwe, ukwesaba ukushiswa yi-oxidation, kungasetshenziswa ngokuphindaphindiwe.

Iphutha: Ukucindezeleka akukuhle kakhulu, kulula ukukuqeda.

3. Izinto ze-OPP (i-polypropylene eqondiswe ku-OPP):

Izinzuzo: ukucaca okuphezulu, ukuvalwa okuhle.

Amaphutha: ukucindezeleka akwanele, kulula ukukuphula, futhi ukuphrinta kulula kakhulu ukususa umbala.

4. I-PVC (i-polyvinyl chloride):

Izinzuzo: ukuphepha nempilo, ukuqina, ubuhle nokusebenziseka kalula, ukuma okuhle, izitayela ezahlukahlukene.

Amaphutha: ukuvikelwa kwemvelo okungekuhle, okuqukethe i-chlorine, ukusha kuzokhiqiza amagesi ayingozi.

Ifilimu yesikhwama sezingubo sepulasitiki yezinto ezingenhla inezici zayo, futhi ukukhetha kungasuselwa ezidingweni ezithile kanye nokucabangela izindleko, ukuvikelwa kwemvelo kanye nezinye izici ukuze kunqunywe ukuthi iyiphi impahla okufanele isetshenziswe. Isikhwama sezingubo siwumkhiqizo “wejazi”, ngaphezu kokuhlobisa ukupakisha, into ebaluleke kakhulu ukudlala ukupakisha okuzimele, isitoreji, ukuvikelwa nokunye. Lapho izingubo zithambile, kulapho kudingeka khona ukuvikelwa kwesikhwama sokupakisha, ukuze kugwenywe ukuthi izingubo zingcoliswe noma zithinteke nothuli nezinye izinto ezingcolile.

Ngakho-ke, izikhwama zezingubo zibalulekile embonini yezingubo. Kodwa-ke, ifilimu yokupakisha izingubo kulula ukuyibona enkambisweni yokusetshenziswa nokuthuthwa: i-coefficient yokungqubuzana kwesikhwama sezingubo ayizinzile, imvula yempuphu ingcolise izingubo nezinye izinkinga.

Izithasiselo ze-SILIMER ezingaqhakazi, Xazulula inkinga yokufuduka kwempuphu kusuka kufilimu yesikhwama sezingubo

Ukuthuthukiswa kweIzithasiselo ze-superslip ze-SILIKE SILIMER ezingafudukikuyintsha efilimini yesikhwama sezingubo. Ngokungafani ne-ejenti yendabuko yokushelela enesisindo esincane sama-molecule, i-SILIMER engasheleli i-SILIMER ingumkhiqizo omusha we-polysiloxane oshintshiwe we-copolymerized. Ama-molecule ayo aqukethe izingxenye zeketanga le-polysiloxane kanye namaqembu asebenzayo aneketanga le-carbon elide. Amaketanga e-carbon amade ahambisana nama-resin ukuze adlale indima yokubambelela, kanye namaketanga e-silicon ahlukaniswe ebusweni befilimu ukuze adlale indima yokushelela. Ukuze idlale indima ebushelelezi ngaphandle kokuna ngokuphelele, kusukela empandeni kuya ekuxazululeni inkinga yesikhwama sezingubo ifilimu yokunameka kwempuphu ukungcoliswa kwezingubo.

Okulandelayo yizinzuzo ze-I-SILIKEI-masterbatch ye-SILIMER's slip engeyona imvula ekusetshenzisweni kwefilimu yesikhwama sezingubo:

Impuphu ebushelelezi nengenamvula ehlala isikhathi eside:kuthuthukisa kakhulu ukushelela, kunciphisa i-dynamic and static friction coefficient, i-smooth ehlala isikhathi eside ngaphandle kwemvula, ukugwema ukungcola kwezingubo okubangelwa yimpuphu yemvula.

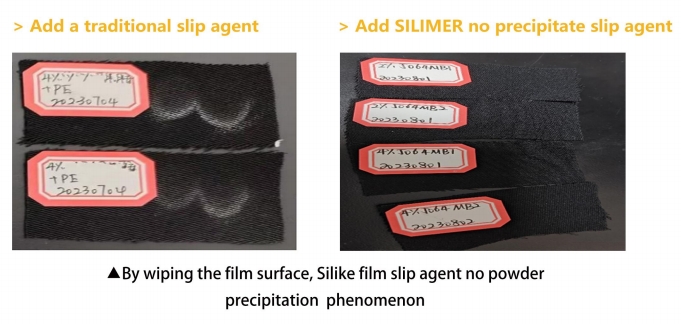

Njengoba kuboniswe esithombeni esingezansi, ubuso befilimu bune-ejenti yendabuko yokwehlisa ama-molecule aphansi kanye nobuso obune-U-SILIKE SILIMER umenzeli wokushelela ongaqhakazizasulwa ngendwangu emnyama. Kungabonakala ukuthi uma kuqhathaniswa nokusetshenziswa kwezithasiselo zendabuko eziphansi zama-molecule,Izithasiselo ze-SILIKE SILIMER Ezingafudukiayisheshisi isenzakalo sempuphu.

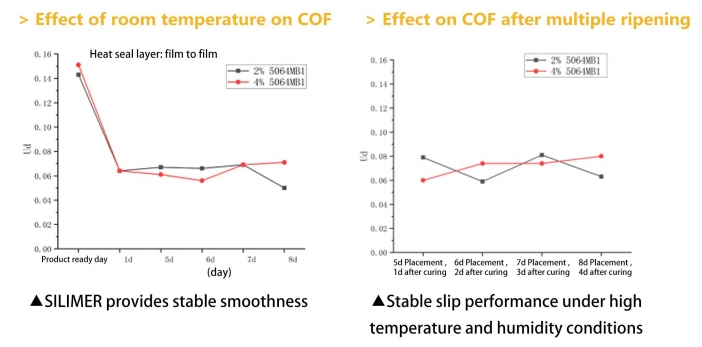

Ukumelana nokushisa okuphezulu, i-coefficient eqinile yokungqubuzana:ukumelana okuhle nokushisa okuphezulu, ukuhambisana okuhle kakhulu ne-matrix resin, ngeke kubangelwe ukugcinwa kokushisa okuphezulu, ukuthuthwa noma izinguquko zokushisa, njenge-coefficient yokungqubuzana engaguquki, engazinzile kanye nezinye izimo.

Njengoba kuboniswe ngezansi, izimo zokuphulukisa: izinga lokushisa 45℃, umswakama 85%, isikhathi 12h, izikhathi ezine.

Umkhiqizo uzinzile nge-COF ngemva kokwelashwa kwezindawo ezishisayo nezinomswakama ophezulu izikhathi eziningi, ifilimu ilungiselelwa ikhasimende, izendlalelo ezinhlanu zefilimu evuvukile, ubukhulu obungama-microns ayi-100. Kungabonakala ukuthi ngemva kokusetshenziswa kweIzithasiselo ze-super slip ezingafuduki ze-SILIKE SILIMER, ifilimu inokumelana okuhle nokushisa okuphezulu kanye ne-coefficient eqinile yokungqubuzana.

Umswakama ophansi:akukuthinti ukusetshenziswa kwezigcawu ezidinga ukucaca.

Ukuqina okuphezulu:akukuthinti ukuphrinta, ukuhlanganiswa kanye nokunye ukucubungula okulandelayo.

Kusetshenziswa kabanzi:ingasetshenziswa kumafilimu e-BOPP, CPP, PE, PP nakwamanye.

Thuthukisa ukusebenza kokucubungula kanye nezakhiwo zomphezulu wefilimu, unikeze ukushelela kokushisa okuphezulu kwesikhathi eside, ugweme i-powder yemvula, sinolwazi olucebile kanye namacala amaningi aphumelelayo, uma ufuna izixazululo zokuguqulwa kwezinto ezihlobene, sicela uxhumane ne-SILIKE!

I-Chengdu SILIKE Technology Co., Ltd, i-China ehamba phambiliIsengezo se-SiliconeUmhlinzeki wepulasitiki eguquliwe, unikeza izixazululo ezintsha zokuthuthukisa ukusebenza kanye nokusebenza kwezinto zepulasitiki. Siyakwamukela ukuxhumana nathi, i-SILIKE izokunikeza izixazululo zokucubungula ipulasitiki ezisebenza kahle.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

iwebhusayithi:www.siliketech.comukuze ufunde kabanzi.

Isikhathi sokuthunyelwe: Novemba-05-2024