Ukunisela ngempuphu emhlophe ezikhwameni zokupakisha zefilimu ehlanganisiwe kuyinkinga ephindaphindayo ehlupha abakhiqizi emhlabeni jikelele. Le nkinga engathandeki ayigcini nje ngokunciphisa ukubukeka komkhiqizo wakho kodwa futhi iphakamisa ukukhathazeka okukhulu ngekhwalithi kanye nokuhlanzeka, ikakhulukazi ezimbonini ezifana nokudla, imithi, kanye nezimonyo. Kulesi sihloko, sihlola izimbangela eziyinhloko zokunisela ngempuphu emhlophe, umthelela wayo ekukhiqizweni, futhi sethulaI-SILIKE's SILIMER Series Super Slip Masterbatch— izixazululo zokungcoliswa kwefilimu eziqeda izinkinga zempuphu ngenkathi zithuthukisa ukusebenza kwefilimu.

Inselele: Yini Ebangela Ukuwa Kwempuphu Emhlophe?

Impuphu emhlophe evame ukubonakala ezikhwameni zokupakisha zefilimu ehlanganisiwe iwumphumela wezinto ezishelelayo—njenge-oleic acid amide kanye ne-erucic acid amide—ezithuthela phezulu.ama-ejenti okushelelazisebenza ngokwakha ungqimba lokugcoba lwama-molecule olunciphisa i-coefficient yokungqubuzana kwefilimu. Kodwa-ke, isisindo sazo esincane sama-molecule sizenza zithambekele ekwehleni kwemvula, okuholela ekwakhekeni kwempuphu emhlophe ebonakalayo.

Lesi simo sidala umphumela wezinkinga eziningi:

1. Ukungcoliswa kwe-Composite Roller: Ngesikhathi senqubo yokuhlanganisa, impuphu emhlophe inganqwabelana kuma-composite roller. Lokhu kwakheka kungaphazamisa ukusebenza kahle kwemishini yakho, okuholela ekungasebenzeni kahle kanye namaphutha angaba khona kwifilimu yokugcina.

2. Ukunamathela kwe-Rubber Roller: Njengoba ifilimu iqhubeka nokucutshungulwa, i-powder ingadluliselwa kuma-rubber roller, okuholela ezinkingeni zokunamathela. Lokhu akugcini nje ngokuthinta imishini yokucubungula kodwa futhi kuholela ekudluliselweni kwe-powder kumkhiqizo wokugcina, okuphazamisa ukubukeka kwayo.

3. Ukukhathazeka Ngekhwalithi Nokuhlanzeka: Ukuba khona kwempuphu emhlophe ezikhwameni zokupakisha kuphakamisa ukukhathazeka okukhulu mayelana nokuhlanzeka komkhiqizo, ikakhulukazi ezimbonini lapho ukuhlanzeka kubaluleke kakhulu. Kungaholela ekuboneni ikhwalithi yomkhiqizo ephansi futhi kungaphula ngisho nezindinganiso zokuhlanzeka emikhakheni elawulwayo njengokupakisha ukudla.

Lezi zinselele azigcini nje ngokwandisa izindleko zokukhiqiza kodwa futhi zibangela ukunganeliseki kwamakhasimende, okwenza kube yimfuneko ukuthola ikhambi elithembekile.

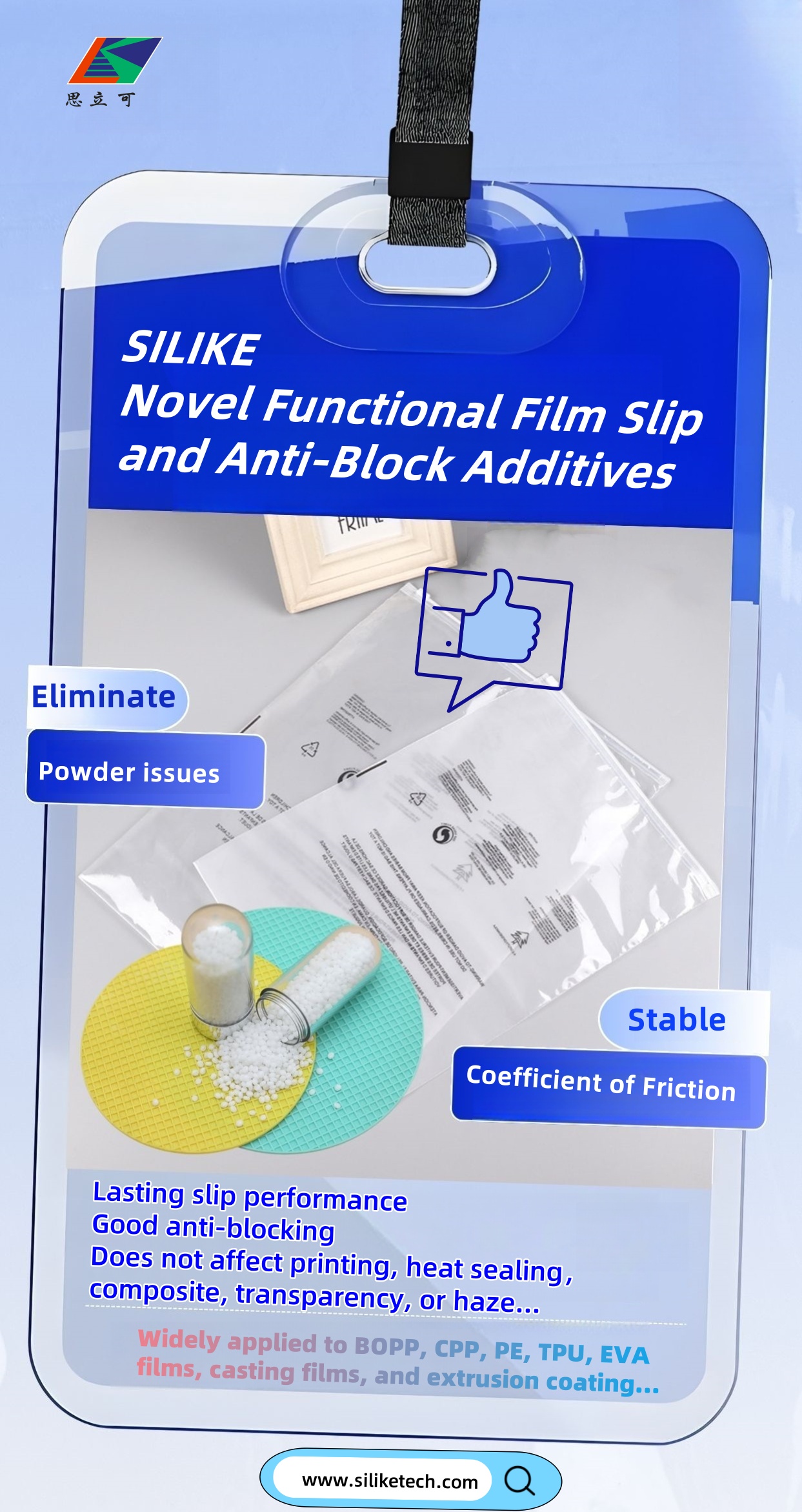

Isixazululo: Uchungechunge lwe-SILIKE SILIMERI-Super Slip & Anti-Blocking Masterbatch– Isihluthulelo Sokupakishwa Okuhlanzekile Nekhwalithi Ephakeme

Qamba Izinto Ezintsha Ngaphandle Kwezithako Zendabuko Zokushelela

Kwa-SILIKE, siyaqonda izinselele ezibhekene nabakhiqizi bamafilimu ahlanganisiwe. Yingakho sakha uchungechunge lwe-SILIMERI-Super Slip Masterbatch—anisisombululo sokushelela esithuthwayoyakhelwe ukuqeda ukuna kwempuphu ngenkathi inikeza ukusebenza okungenakuqhathaniswa njengeisiliphu sefilimu esisebenzayo kanye nesithasiselo sokulwa nokuvimba.

Izinzuzo Eziyinhloko zeIzithasiselo ze-SILIKE SILIMER ezithambile nezivimbela ukuvimba

1. Iqeda Izinkinga Zempuphu: Ifomula yethu ethuthukisiwe ivimbela ukufuduka kwe-slip agent, ixazulula imvula elula yempuphu emhlophe.

2. Ukusebenza Okushelelayo Okuhlala Njalo: Kugcina i-coefficient ezinzile nephansi yokungqubuzana kuyo yonke impilo yefilimu.

3. I-Anti-Blocking Ephakeme: Ithuthukisa ukuphathwa kwefilimu futhi ivimbela izendlalelo ukuthi zinganamatheli ndawonye.

4. Ukushelela Okuthuthukisiwe Komphezulu: Kuletha isiphetho esihle nesichwepheshile sokupakisha okuphezulu.

5. Akukho Ukuhlehla Ezimpahleni Zefilimu: Akukuthinti ukuphrinta, ukuvala ukushisa, ukuhlanganiswa, ukucaca, noma umswakama.

6. Iphephile Futhi Ayinaphunga: Ihambisana nezindinganiso zomthetho zomhlaba wonke, okwenza kube kuhle kakhulu ekupakisheni ukudla kanye nemithi.

Uchungechunge lwe-SILIMERizithasiselo zefilimu ezisebenzayoZiyakwazi ukusetshenziswa ngezindlela eziningi futhi zifanele ukusetshenziswa kwepulasitiki okuhlukahlukene, okuhlanganisa:Amafilimu e-BOPP, CPP, PE, kanye ne-PP, Amafilimu namashidi okupakisha, Imikhiqizo ye-Polymer edinga izakhiwo ezithuthukisiwe zokushelela kanye nobuso.

I-SILIKE ingumholi othembekile kwezengezo ezisebenzayo kanye nezixazululo ze-masterbatch zamafilimu epulasitiki, enomlando oqinisekisiwe wokusungula izinto ezintsha kanye nokwaneliseka kwamakhasimende. Izithasiselo zethu ze-SILIMER Series Non-Migrating Slip & Anti-Block ziwumphumela we-R&D ebanzi, eyenzelwe ukuhlangabezana nezidingo ezithile zabakhiqizi bamafilimu ahlanganisiwe. Valelisa ekunisweni kwempuphu emhlophe ezikhwameni zokupakisha amafilimu ahlanganisiwe.

Vakashelawww.siliketech.comukuze ufunde kabanzi ngochungechunge lwe-SILIKE's SILIMER—lwakhoikhambi eliphumelelayo lezithasiselo zefilimu ezisebenzayo, inikeza isiphetho esibushelelezi nesihlanzekile samafilimu akho okupakisha ahlanganisiwe!

Isikhathi sokuthunyelwe: Mashi-26-2025