Indima kaIzithasiselo zepulasitikiEkuthuthukiseni Izakhiwo Ze-Polymer:Amapulasitiki anethonya kuyo yonke imisebenzi empilweni yanamuhla futhi amaningi athembele ngokuphelele emikhiqizweni yepulasitiki.

Yonke le mikhiqizo yepulasitiki yenziwe nge-polymer ebalulekile exutshwe nenhlanganisela yezinto eziyinkimbinkimbi,kanye nezithasiselo zepulasitiki yizinto ezifakwa kulezi zinto ze-polymer ngesikhathi sokucutshungulwa kwazo ukuze kuthuthukiswe noma kuguqulwe izakhiwo zazo. Ngaphandle kwezithasiselo zepulasitiki, amapulasitiki ngeke asebenze, kodwa ngawo, angenziwa aphephe, aqine, abe nombala, akhululeke, abe nobuhle futhi abe wusizo.Kunezinhlobo eziningana zezithasiselo zepulasitiki ezitholakalayo, ngayinye inomsebenzi wayo othize. Nazi ezinye zezigaba ezivamile:

Iziqinisi: Lezi zithasiselo zisiza ukuvikela amapulasitiki ekuwohlokeni okubangelwa ukushisa, ukukhanya, noma i-oxidation. Zivimbela ukufiphala kombala, ukuqhekeka, noma ukulahlekelwa yizakhiwo zemishini.

Ama-plasticizer: Ama-plasticizer andisa ukuguquguquka nokusebenza kahle kwamapulasitiki. Anciphisa ukuphuka futhi enze izinto zibe lula futhi kube lula ukuzicubungula. Ama-plasticizer avamile afaka phakathi ama-phthalates.

Izinto ezivimbela ilangabi: Lezi zithasiselo zithuthukisa ukumelana nomlilo kwamapulasitiki ngokunciphisa ukusha kwawo kanye nokunciphisa ukusabalala kwamalangabi.

Ama-Antioxidant: Ama-Antioxidant avimbela ukuwohloka kwepulasitiki okubangelwa ukuchayeka ku-oxygen, ngaleyo ndlela andise isikhathi sawo sokuphila futhi alondoloze izakhiwo zawo zomzimba.

Iziqinisi ze-UV: Lezi zithasiselo zivikela ipulasitiki emiphumeleni elimazayo yemisebe ye-ultraviolet (UV), njengokushintsha kombala, ukuwohloka, noma ukulahlekelwa amandla.

Izinto Zokufaka Umbala: Izinto zokufaka umbala ziyizithasiselo ezihlinzeka ngombala kumapulasitiki, ziwanike umbala noma ukubukeka okufiselekayo.

Ama-Filler: Ama-Filler ayizithasiselo ezisetshenziselwa ukuguqula izakhiwo zemishini zepulasitiki. Angathuthukisa ukuqina, amandla, kanye nokuzinza kobukhulu ngenkathi enciphisa izindleko.

Izinto zokugcoba: Izinto zokugcoba zengezwa kumapulasitiki ukuze kuthuthukiswe ukucutshungulwa kwazo ngokunciphisa ukungqubuzana ngesikhathi sokubumba noma ukubumba.

Iziguquli zomthelela: Lezi zithasiselo zithuthukisa ukumelana komthelela wepulasitiki, okwenza zingaqhekeki noma ziqhekeke ngaphansi kokucindezeleka.

Izinto ezivimbela ugesi: Izithasiselo ezivimbela ugesi zinciphisa noma ziqeda ukwakheka kukagesi oqinile ebusweni bepulasitiki, okwenza kube lula ukuthi zidonse uthuli noma zibangele ukushaqeka kukagesi.

Ukucubungula izithasiselo: obeye aziwe njengoizinsiza zenqubo,yizinto ezifakwa ezintweni zepulasitiki ngesikhathi sokukhiqiza noma sokucubungula ukuze kuthuthukiswe ukuphathwa, ukusebenza, noma izici zokucubungula izinto.

Lezi zithasiselo zokucubungula zivame ukusetshenziswa ngobuningi obuncane futhi zingathinta kakhulu inqubo yokukhiqiza ngokuthuthukisa ukugeleza kwezinto, ukunciphisa amaphutha, ukuthuthukisa ukukhishwa kwesikhunta, kanye nokwenza ngcono ukusebenza kokukhiqiza okuphelele.

Lezi yizibonelo ezimbalwa nje zeizithasiselo zepulasitiki.Ukukhethwa kanye nokuhlanganiswa kwezithasiselo kuncike enkambisweni ethile yokukhiqiza, imishini, izakhiwo ezifiselekayo zomkhiqizo wokugcina wepulasitiki, kanye nokusetshenziswa okuthile okuhloswe ngakho.

Yini Eyengezwayo Ezintweni Zepulasitiki Ze-Polymer?

Bheka lapha ukuthola amanothi akhethekile:

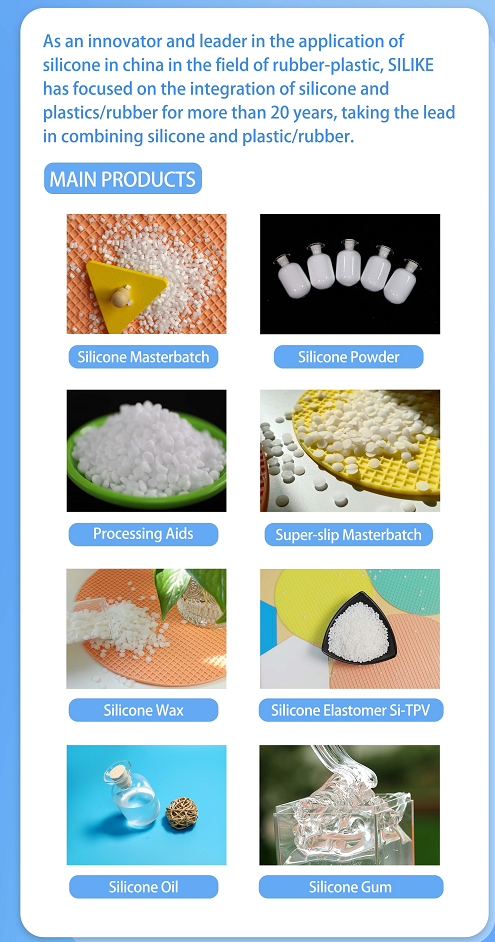

I-silicone masterbatch uhlobo lwe-ukucubungula izithasiseloembonini yerabha nepulasitiki. Ubuchwepheshe obuthuthukisiwe emkhakheni wezithasiselo ze-silicone ukusetshenziswa kwe-silicone polymer (PDMS) ye-silicone enesisindo esikhulu kakhulu (UHMW) kuma-resin ahlukahlukene e-thermoplastic, njenge-LDPE, i-EVA, i-TPEE, i-HDPE, i-ABS, i-PP, i-PA6, i-PET, i-TPU, i-HIPS, i-POM, i-LLDPE, i-PC, i-SAN, njll. Futhi njengama-pellets ukuze kube lula ukufaka isithasiselo ngqo kwi-thermoplastic ngesikhathi sokucubungula. kuhlanganisa ukucubungula okuhle kakhulu ngezindleko ezingabizi. Zisetshenziswa kabanzi ekucubungulweni okuthuthukisiwe kwepulasitiki kanye nekhwalithi ephezulu yezingxenye eziqediwe zezimoto zangaphakathi, izintambo kanye nezintambo, amapayipi okuxhumana, izicathulo, ifilimu, ukumboza, indwangu, izinto zikagesi, ukwenza iphepha, ukupenda, ukuhlinzekwa kokunakekelwa komuntu siqu, kanye neminye imboni. Kuhlonishwa njenge-"monosodium glutamate yezimboni".

Ngaphezu kwakho konke, i-SILIKE'si-silicone masterbatchisebenza njengethuluzi elisebenza kahle kakhuluizinsiza zokucubungulaKulula ukuphakela, noma ukuxuba, kumapulasitiki ngesikhathi sokuhlanganiswa, ukukhishwa, noma ukubumba ngomjovo. Kungcono kunowoyela we-wax wendabuko kanye nezinye izithasiselo ekuthuthukiseni ukushelela ngesikhathi sokukhiqiza. Ngenxa yesisindo sama-molecule aphezulu kakhulu e-silicone masterbatch, okwakha ungqimba lokuthambisa phakathi kwamapulasitiki kanye nama-extruder, okuhlakazeka ngokulinganayo ohlelweni, okwenza kube lula ukucubungula amapulasitiki, njengesivinini esisheshayo sokukhishwa, ukucindezela okuncane kokufa, kanye nokuvuza kokufa, ukuphuma okukhulu, ukugcwaliswa kwesikhunta okulula, kanye nokukhululwa kwesikhunta, njll.

Okwamanje, ikhwalithi engaphezulu yepulasitiki ingathuthukiswa, njengokuqina okuphansi kokungqubuzana, ukuzwela kwesandla okushelelayo kakhulu, ukumelana nokuklwebheka, ukumelana nokuklwebheka, ukuzwela kwesandla okomile nokuthambile, njll.

Kanjaniizithasiselo zepulasitiki ze-silicone masterbatchingashintsha izakhiwo zomzimba, zemishini, nezamakhemikhali zama-polymer?

Sicela usithinte ukuze ufunde kabanzi ngobuchwepheshe bezinhlelo zokusebenza!

e-mail:amy.wang@silike.cn

Isikhathi sokuthunyelwe: Julayi-13-2023