I-color masterbatch iyindlela evame kakhulu yokufaka imibala epulasitikini, esetshenziswa kabanzi embonini yokucubungula amapulasitiki. Enye yezinkomba zokusebenza ezibaluleke kakhulu ze-masterbatch ukusabalala kwayo. Ukusabalala kubhekisela ekusabalaleni okufanayo kombala ngaphakathi kwezinto zepulasitiki. Kungakhathaliseki ukuthi kusekubunjweni komjovo, ekukhipheni, noma ekubunjweni komoya, ukusabalala okungekuhle kungaholela ekusabalaleni kombala okungalingani, imicu engajwayelekile, noma amachashazi kumkhiqizo wokugcina. Le nkinga iyinkinga enkulu kubakhiqizi, futhi ukuqonda izimbangela nezixazululo kubalulekile ekugcineni ikhwalithi yomkhiqizo.

Izimbangela Zokuhlakazeka Okubi Ku-Masterbatch Yombala

Ukuhlanganiswa Kwemibala

I-Masterbatch iyinhlanganisela egxile kakhulu yama-pigment, futhi amaqoqo amakhulu ala ma-pigment angathinta kakhulu ukuhlakazeka. Ama-pigment amaningi, njenge-titanium dioxide kanye ne-carbon black, avame ukuhlangana ndawonye. Ukukhetha uhlobo olufanele kanye nosayizi wezinhlayiya ze-pigment ngokuya ngomkhiqizo wokugcina kanye nendlela yokucubungula kubalulekile ukuze kufezwe ukuhlakazeka okuhle.

Imiphumela ye-Electrostatic

Ama-masterbatch amaningi awafaki ama-antistatic agents. Uma i-masterbatch ixutshwa nezinto zokusetshenziswa, ugesi ongaguquki ungakhiqizwa, okuholela ekuxubeni okungalingani kanye nokusatshalaliswa kombala okungaguquki kumkhiqizo wokugcina.

Inkomba Yokuncibilika Engafaneleki

Abahlinzeki bavame ukukhetha ama-resin ane-melt index ephezulu njengesithwali se-masterbatch. Kodwa-ke, i-melt index ephezulu ayihlali ingcono. I-melt index kufanele ikhethwe ngokucophelela ukuze ihambisane nezakhiwo zomzimba nezidingo zomphezulu womkhiqizo wokugcina, kanye nezici zokucubungula ze-masterbatch. I-melt index ephansi kakhulu ingabangela ukuhlakazeka okubi.

Isilinganiso Esiphansi Sokwengeza

Abanye abahlinzeki baklama i-masterbatch enesilinganiso esiphansi sokwengeza ukuze banciphise izindleko, okungabangela ukuhlakazeka okunganele ngaphakathi komkhiqizo.

Uhlelo Lokuhlakazeka Olunganele

Ama-dispersing agents kanye nama-lubricant ayengezwa ngesikhathi senqubo yokukhiqiza i-masterbatch ukusiza ukuphula amaqoqo e-pigment. Uma kusetshenziswa ama-dispersing agents angafanele, kungaholela ekuhlakazekeni okubi.

Ukungalingani Kobuningi

Ama-Masterbatch avame ukuqukethe ama-pigment anesisindo esikhulu, njenge-titanium dioxide, enobukhulu obungaba ngu-4.0g/cm³. Lokhu kuphakeme kakhulu kunobukhulu bama-resin amaningi, okuholela ekuqhekekeni kwe-masterbatch ngesikhathi sokuxuba, okubangela ukusatshalaliswa kombala okungalingani.

Ukukhetha Okungafanele Kwenkampani Yenethiwekhi

Ukukhethwa kwe-carrier resin, ephethe imibala kanye nezithasiselo, kubalulekile. Izici ezifana nohlobo, ubuningi, ibanga, kanye ne-melt index ye-carrier, kanye nokuthi ngabe isesimweni sempuphu noma se-pellet, konke kungathonya ikhwalithi yokusabalala kokugcina.

Izimo Zokucubungula

Izimo zokucubungula ze-masterbatch, okuhlanganisa uhlobo lwemishini, izinqubo zokuxuba, kanye namasu okufaka i-pelletizing, zidlala indima ebalulekile ekusabalaleni kwayo. Ukukhetha okufana nokuklama imishini yokuxuba, ukucushwa kwezikulufo, kanye nezinqubo zokupholisa konke kuthinta ukusebenza kokugcina kwe-masterbatch.

Umthelela Wezinqubo Zokubumba

Inqubo ethile yokubumba, njengokubumba ngomjovo, ingathinta ukuhlakazeka. Izici ezifana nokushisa, ingcindezi, kanye nesikhathi sokubamba zingathinta ukufana kokusabalala kombala.

Ukugqoka Imishini

Imishini esetshenziswa ekubumbeni ngepulasitiki, njengezikulufo ezigugile, inganciphisa amandla okusika, yenze buthaka ukusabalala kwe-masterbatch.

Umklamo Wesikhunta

Ngokubumba ngomjovo, indawo yesango nezinye izici zokuklama isikhunta kungathinta ukwakheka komkhiqizo kanye nokuhlakazeka. Ekukhipheni, izici ezifana nokwakheka kwedayi kanye nezilungiselelo zokushisa nazo zingathinta ikhwalithi yokuhlakazeka.

Izixazululo Zokuthuthukisa Ukusabalala ku-Color Masterbatch, ukugxila kombala kanye nezinhlanganisela

Uma ubhekene nokuhlakazeka okubi, kubalulekile ukubhekana nenkinga ngendlela ehlelekile:

Bambisana Kuzo Zonke Izigaba: Ngokuvamile, izinkinga zokuhlakazeka azibangelwa nje yizinto ezibonakalayo noma izici zenqubo. Ukubambisana phakathi kwabo bonke abathintekayo, okuhlanganisa abahlinzeki bezinto ezibonakalayo, onjiniyela bezinqubo, kanye nabakhiqizi bemishini, kubalulekile ekuboneni nasekubhekaneni nezimbangela eziyinhloko.

Lungiselela Ukukhetha I-Pigment:Khetha imibala enosayizi wezinhlayiya ezifanele kanye nohlobo lokusetshenziswa okuthile.

Lawula Ugesi Ongaguquki:Faka ama-antistatic agents lapho kudingeka khona ukuze uvimbele ukuxubana okungalingani.

Lungisa i-Melt Index:Khetha izinkampani zokuthwala ezinenkomba yokuncibilika ehambisana nezimo zokucubungula kanye nezidingo zomkhiqizo.

Izilinganiso Zokwengeza Buyekeza: Qinisekisa ukuthi i-masterbatch yengezwe ngobuningi obanele ukuze kufezwe ukuhlakazeka okufiselekayo.

Lungisa Uhlelo Lokuhlakazeka:Sebenzisa izinto zokusabalalisa ezifanele kanye nezinto zokugcoba ukuze uthuthukise ukuqhekeka kwama-pigment agglomerate.

Ubuningi bokufana:Cabanga ngobuningi bemibala kanye nama-carrier resins ukuze ugweme ukubola kwenhlabathi ngesikhathi sokucubungula.

Amapharamitha Okucubungula Okuhle:Lungisa izilungiselelo zemishini, njengezinga lokushisa kanye nokucushwa kwezikulufo, ukuze uthuthukise ukusabalala.

Ukuqamba izinto ezintshaIzixazululo Zokuthuthukisa Ukusabalala ku-Color Masterbatch

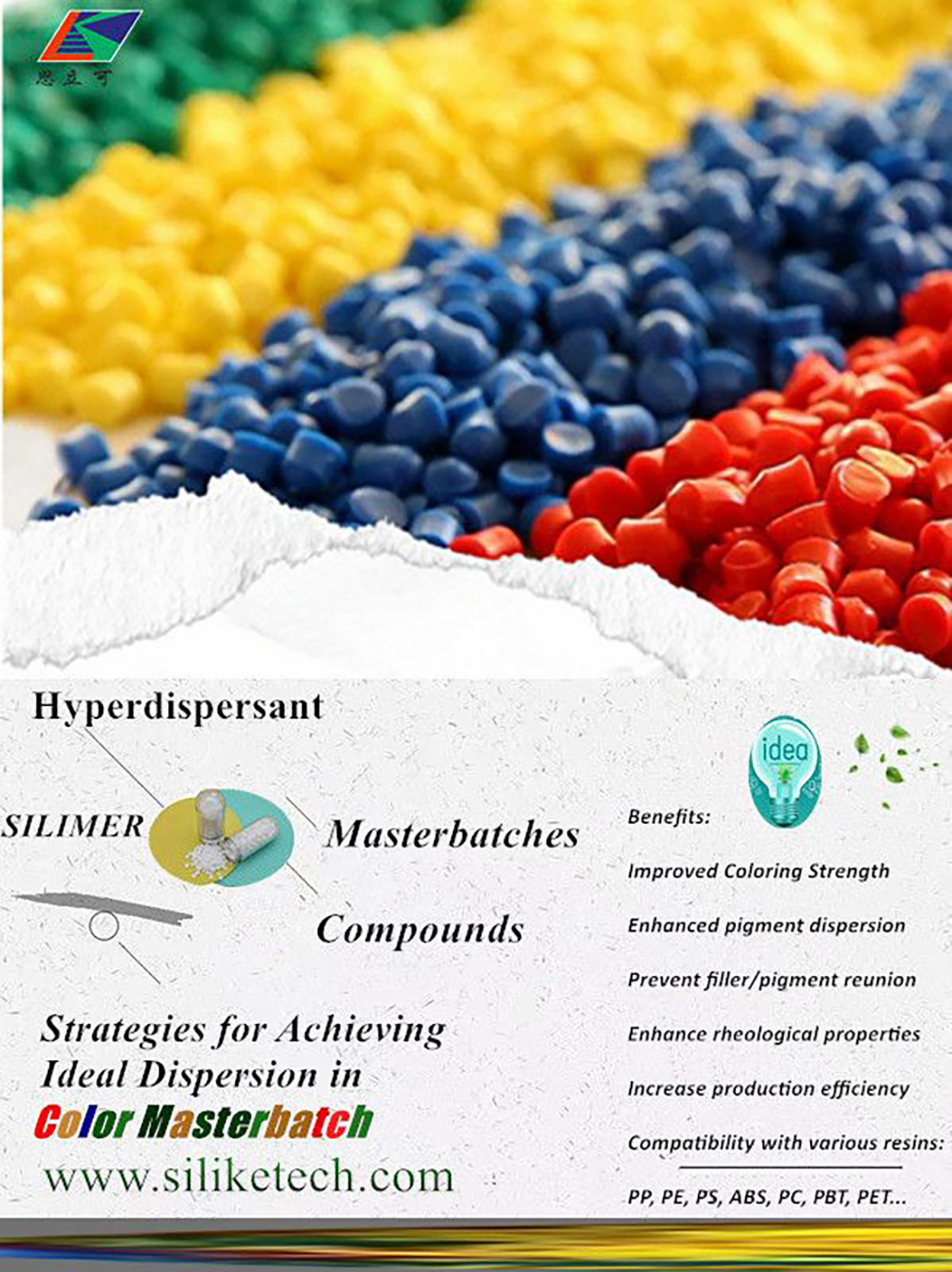

I-Novel Silicone hyperdispersant, indlela ephumelelayo yokuxazulula ukusabalala okungalingani kuma-Color Masterbatches ngeI-SILIKE SILIMER 6150.

I-SILIMER 6150iyi-wax ye-silicone eguquliwe esebenza njenge-hyperdispersant ephumelelayo, eyenzelwe ngqo ukuthuthukisa ikhwalithi yama-color concentrate, ama-masterbatches, kanye nama-compounds. Kungakhathaliseki ukuthi i-single pigment dispersion noma ama-color concentrate enziwe ngokwezifiso, i-SILIMER 6150 ihamba phambili ekuhlangabezaneni nezidingo zokuhlakazeka ezidinga kakhulu.

Aizinzuzo ze I-SILIMER 6150ngezixazululo ze-color masterbatch:

Ukusabalala Kwemibala Okuthuthukisiwe: I-SILIMER 6150kuqinisekisa ukusatshalaliswa okufanayo kwama-pigment ngaphakathi kwe-matrix yepulasitiki, kususa imicu noma amachashaza ombala futhi kuqinisekiswe ukuthi umbala ulingana kuyo yonke into.

Amandla Okufaka Umbala Athuthukisiwe:Ngokwenza ngcono ukuhlakazeka kombala,I-SILIMER 6150kuthuthukisa amandla okufaka imibala jikelele, okuvumela abakhiqizi ukuthi bafinyelele ubukhali bombala obufunwayo nge-pigment encane, okuholela ekukhiqizweni okuphumelelayo nokungabizi kakhulu.

Ukuvimbela Ukuhlanganiswa Kokugcwalisa Nokuhlanzwa Kwemibala: I-SILIMER 6150kuvimbela ngempumelelo imibala kanye nama-filler ukuthi angahlangani ndawonye, okuqinisekisa ukusabalala okuzinzile nokungaguquguquki kulo lonke ukucubungula.

Izakhiwo Ezingcono Ze-Rheological: I-SILIMER 6150akugcini nje ngokuthuthukisa ukuhlakazeka kodwa futhi kuthuthukisa izakhiwo ze-rheological ze-polymer melt. Lokhu kuphumela ekucutshungulweni okubushelelezi, ukuncipha kwe-viscosity, kanye nezici zokugeleza ezithuthukisiwe, ezibalulekile ekukhiqizweni kwepulasitiki esezingeni eliphezulu.

IUkwanda Kokusebenza Kahle Kokukhiqiza kanye Nokunciphisa Izindleko: Ngokusabalala okuthuthukisiwe kanye nezakhiwo ezingcono ze-rheological,I-SILIMER 6150kuthuthukisa ukusebenza kahle kokukhiqiza, okuvumela izikhathi zokucubungula ezisheshayo kanye nokunciphisa imfucuza yezinto ezibonakalayo, ekugcineni kunciphisa izindleko zokukhiqiza zizonke.

Ukuhambisana Okubanzi: I-SILIMER 6150iyahambisana nohlu olubanzi lwama-resin, kufaka phakathi i-PP, i-PE, i-PS, i-ABS, i-PC, i-PET, kanye ne-PBT, okwenza kube ukukhetha okuhle kakhulu kwezicelo ezahlukahlukene embonini ye-masterbatch kanye ne-compounds plastics.

Thuthukisa ukukhiqizwa kwe-color masterbatch yakho ngeI-SILIMER 6150ukuze kusakazwe umbala ngendlela engcono kakhulu kanye nokusebenza kahle komkhiqizo. Susa imicu yemibala futhi uthuthukise ukusebenza kahle. Ungaphuthelwa—thuthukisa ukusakazwa, wehlise izindleko, futhi uphakamise ikhwalithi yakho ye-masterbatch.Xhumana noSilike namuhla! Ucingo: +86-28-83625089, I-imeyili:amy.wang@silike.cn,Vakashelawww.siliketech.comukuthola imininingwane.

Isikhathi sokuthunyelwe: Agasti-15-2024