I-masterbatch ye-siliconeuhlobo lwesengezo embonini yerabha nepulasitiki. Ubuchwepheshe obuthuthukisiwe emkhakheni wezithasiselo ze-silicone ukusetshenziswa kwe-silicone polymer (PDMS) ye-silicone ye-ultra-high molecular weight (UHMW) kuma-resin ahlukahlukene e-thermoplastic, njenge-LDPE, i-EVA, i-TPEE, i-HDPE, i-ABS, i-PP, i-PA6, i-PET, i-TPU, i-HIPS, i-POM, i-LLDPE, i-PC, i-SAN, njll. Futhi njengama-pellets ukuze kuvunyelwe ukufakwa okulula kwesengezo ngqo kwi-thermoplastic ngesikhathi sokucubungula. kuhlanganisa ukucubungula okuhle kakhulu ngezindleko ezingabizi. I-silicone masterbatch kulula ukuyifaka, noma ukuyixuba, kumapulasitiki ngesikhathi sokuhlanganiswa, ukukhishwa, noma ukubumba ngomjovo. Ingcono kunamafutha e-wax endabuko nezinye izithako ekuthuthukiseni ukushelela ngesikhathi sokukhiqiza. Ngakho-ke, abaprosesa bepulasitiki bakhetha ukuzisebenzisa ekukhipheni.

Izindima zikaIsithasiselo se-Silicone MasterbatchEkuthuthukiseni Ukucutshungulwa Kwepulasitiki

I-silicone masterbatch ingenye yezinketho ezithandwa kakhulu ngabaprosesa ekucutshungulweni kwepulasitiki nasekuthuthukisweni kwekhwalithi yobuso. Njengohlobo lwe-super lubricant. Inemisebenzi eyinhloko elandelayo uma isetshenziswa ku-thermoplastic resin:

A. Thuthukisa ukugeleza kwe-resin kanye nokucubungula;

Izakhiwo ezingcono zokugcwalisa isikhunta kanye nokukhishwa kwesikhunta

Yehlisa i-torque ye-extrude futhi uthuthukise izinga le-extrusion;

B. Kuthuthukisa izakhiwo zobuso be-resin

Thuthukisa ukuqeda kobuso bepulasitiki, izinga elibushelelezi, futhi unciphise i-coefficient yokungqubuzana kwesikhumba, Thuthukisa ukumelana nokuguguleka kanye nokumelana nokuklwebheka;

Futhi i-silicone masterbatch inokuqina okuhle kokushisa (izinga lokushisa lokubola kokushisa licishe libe ngu-430 ℃ ku-nitrogen) futhi ayifuduki;

Ukuvikelwa kwemvelo;

Ukuxhumana ngokuphepha nokudla.

Kumelwe siveze ukuthi yonke imisebenzi ye-silicone masterbatches iphethwe u-A no-B (amaphuzu amabili angenhla esiwabhalile) kodwa akuwona amaphuzu amabili azimele kodwa

ziyanezelana, futhi zihlobene kakhulu.

Imiphumela emikhiqizweni yokugcina

Ngenxa yezici zesakhiwo sama-molecule se-siloxane, umthamo mncane kakhulu ngakho-ke cishe akukho miphumela kumpahla yemishini yemikhiqizo yokugcina. Ngokuvamile, ngaphandle kokwelulwa namandla omthelela kuzokhula kancane, ngaphandle kwemiphumela kwezinye izakhiwo zemishini. Uma umthamo omkhulu, unomphumela wokubambisana nama-agent avimbela ilangabi.

Ngenxa yokusebenza kwayo okuvelele ekumelaneni nokushisa okuphezulu nokuphansi, ngeke kube nemiphumela emibi ekumelaneni nokushisa okuphezulu nokuphansi kwemikhiqizo yokugcina. Ngenkathi ukugeleza kwe-resin, ukucubungula, kanye nezakhiwo zomphezulu kuzothuthukiswa ngokusobala futhi i-COF izoncishiswa.

Indlela yesenzo

Ama-masterbatches e-Siliconekukhona i-polysiloxane enesisindo sama-molecule esiphezulu kakhulu esakazeke kuma-resin ahlukene okuthwala, okuwuhlobo lomsebenzi we-masterbatch. Lapho isisindo sama-molecule esiphezulu kakhuluama-masterbatches e-siliconezengezwa kumapulasitiki ngenxa yokungabi khona kwawo e-polar futhi ngamandla aphansi omhlaba, zinomkhuba wokuthuthela endaweni yepulasitiki ngesikhathi senqubo yokuncibilika; kuyilapho, njengoba inesisindo esikhulu sama-molecule, ayikwazi ukuphuma ngokuphelele. Ngakho-ke sikubiza ngokuthi ukuvumelana nobunye phakathi kokufuduka nokungafuduki. ngenxa yalesi sici, ungqimba lokugcoba oluguquguqukayo lwakhiwa phakathi kwendawo yepulasitiki nesikulufu.

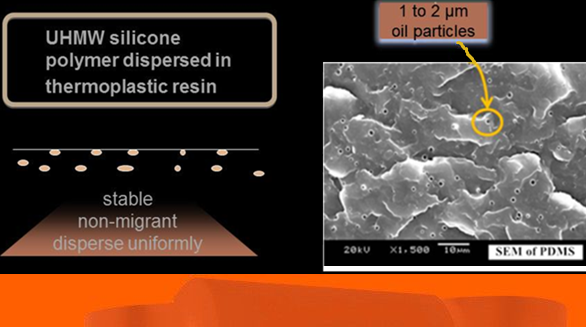

Njengoba ukucubungula kuqhubeka, lolu ngqimba lokuthambisa luhlala lususwa futhi lukhiqizwa. Ngakho-ke ukugeleza kwe-resin nokucubungula kuyathuthuka njalo futhi kunciphisa ugesi, i-torque yemishini futhi kuthuthukiswe umkhiqizo. Ngemva kokucubungula ama-twin-screw, ama-silicone masterbatches azosatshalaliswa ngokulinganayo kumapulasitiki futhi akhe inhlayiya kawoyela engu-1 kuya ku-2-micron ngaphansi kwe-microscope, lawo manhlayiya kawoyela azonikeza imikhiqizo ukubukeka okungcono, umuzwa omuhle wesandla, i-COF ephansi, kanye nokumelana okukhulu kokuklwebheka nokuklwebheka.

Kusukela esithombeni singabona ukuthi i-silicone izoba yizinhlayiya ezincane ngemva kokuhlakazeka kumapulasitiki, into eyodwa okudingeka siyiveze ukuthi ukuhlakazeka kuyinkomba eyinhloko yama-masterbatches e-silicone, uma izinhlayiya zincane, lapho zisakazwa ngokulinganayo, umphumela ongcono esizowuthola.

Isikhathi sokuthunyelwe: Meyi-26-2023