Kungani Ukuvalwa Kokushisa Kwesikhwama Sakho Sepulasitiki Kubuthakathaka? Izimbangela Ezi-4 Zokwehluleka Kokuvalwa Kwesikhwama Sepulasitiki Nezixazululo Eziqinisekisiwe Ezivela Ku-SILIKE

Isingeniso: Izindleko Ezifihliwe Zamandla Okushisa Angemahle

Ekukhiqizweni kwamaphakheji kwanamuhla, izivalo zokushisa ezibuthakathaka noma ezingaguquguquki zihlala zingenye yezinkinga ezivame kakhulu kodwa ezibizayo zekhwalithi.

Idatha yemboni iphakamisa ukuthi cishe u-30% wazo zonke izikhalazo zekhwalithi yokupakisha zihlobene nokwehluleka kokuvala ukushisa. Umphumela? Ukulahlwa kwezinto ezibonakalayo, ukusebenza kahle okuphansi komugqa, kanye nemiphumela emibi njengokuvuza komkhiqizo, ukuncipha kwesikhathi sokuphelelwa yisikhathi, noma ukubuyiselwa kwamakhasimende.

Ngineminyaka engaphezu kwengu-20 yobuchwepheshe ku-izithasiselo ezisebenzayo ezisekelwe ku-silicone,I-SILIKE isebenzisane nabakhiqizi bamafilimu abaphambili ukuthola, ukuhlaziya, nokuxazulula izimbangela ezifihliwe ngemuva kokusebenza kabi kokuvala. Ake sithole isayensi ngemuva kwayo - futhi sihlole izixazululo eziqinisekisiwe.

I. Izimbangela Ezine Eziyinhloko Zokwehluleka Kwesivalo Sokushisa Ekukhiqizeni Ukupakisha

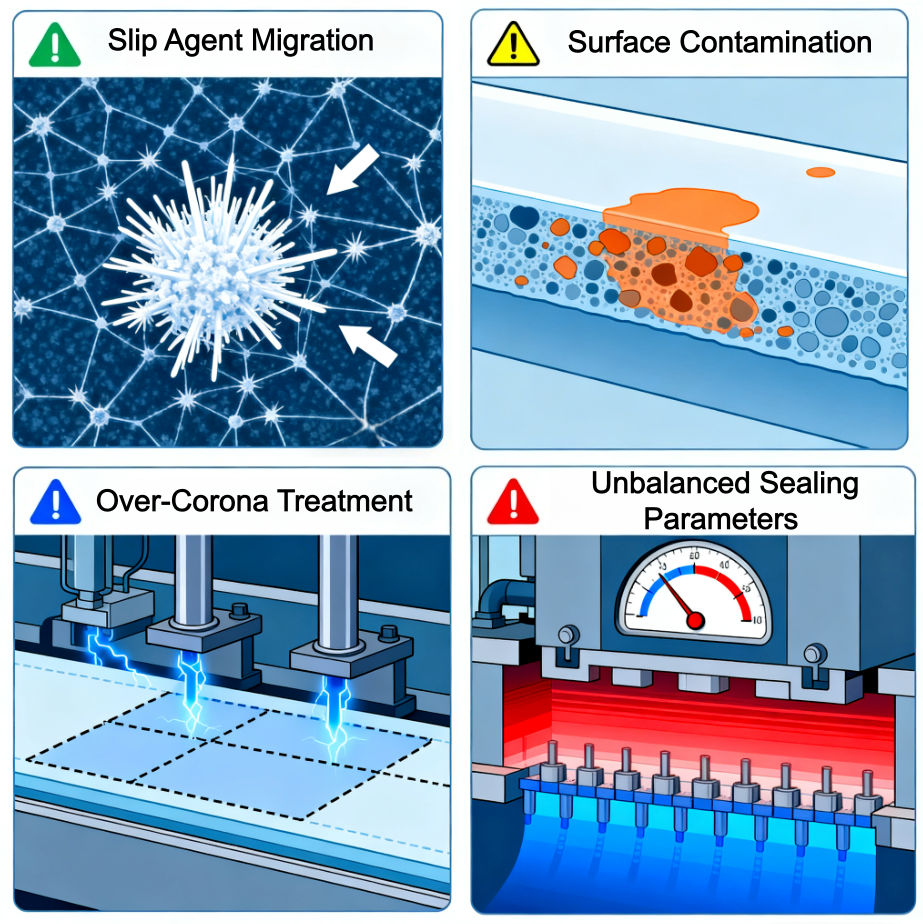

1. Ukufuduka Kwe-Slip Ejenti — Isithiyo Esingabonakali Sezimbozo Zokushisa Eziqinile

Esinye sezimbangela ezinganakwa kakhulu zokuqina kwe-heat seal okungekuhle ukufuduka kwama-slip agents.

Ama-slip agent asekelwe ku-amide njenge-erucamide noma i-oleamide athuthela kancane kancane ebusweni befilimu ngesikhathi sokugcina nokucubungula.

Indlela Echazwe Ngayo:

Ama-molecule athuthayo akha "ifilimu yokugcoba" enezingqimba eziningi noma ezingqimba eziningi ebusweni.

Lolu ngqimba oluncane luhlukanisa ngokoqobo izindawo zokuvala.

Nakuba kunciphisa ukungqubuzana (okuthuthukisa ukuphathwa kwefilimu), futhi kunciphisa ukubopha kwama-molecule phakathi kwezingqimba ngesikhathi sokuvala.

Ama-molecule amancane aphazamisa ukusabalala kwe-polymer chain kanye nokubanjwa endaweni yokuvala.

Izifundo zibonisa ukuthi uma ukufuduka kwe-slip agent kudlula u-15 mg/m², amandla okuvala ukushisa angehla afike ku-50%.

Yingakho abakhiqizi bamafilimu banamuhla beshintshela ezinhlelweni zokwengeza ukushelela ezingaqhakazi — ukuqinisekisa ukusebenza okuhlala njalo kokushelela ngaphandle kokufuduka kobuso.

2. Ukungcoliswa Komphezulu — Uma Ucabanga Ukuthi Kuhlanzekile, Kodwa Akuhlanzekile

Ngisho nezinto ezingcolisayo ezingabonakali njengothuli, umswakama, noma uwoyela osele zingasebenza “njengengqimba yokuzihlukanisa” encane kakhulu, zivimbele ukuvalwa okuphumelelayo.

Izimo Ezijwayelekile Zifaka:

Ukuhlanzwa kwezikulufo okungaphelele ekukhishweni kwefilimu, okuholela ezinhlayiyeni ezifakwe i-carbon.

Inkungu yeyinki evela emigqeni yokunyathelisa engcolisa indawo yokuvala.

Amathiphu Okuvimbela:

Misa amazinga okuhlanzeka kwamafilimu kanye nokuhlolwa okuvamile.

Lawula umswakama kanye nezinhlayiya eziphuma emoyeni endaweni yokukhiqiza.

Sebenzisa ukuhlolwa kokungena kwezinto zokusetshenziswa ukuze kutholakale ikhwalithi yefilimu ehambisanayo.

3. Ukwelashwa Nge-Corona — Lapho Ukuthuthukisa Kuphenduka Ukubhubhisa

Ukwelashwa kwe-corona kusetshenziswa kabanzi ukuthuthukisa amandla ongaphezulu kwefilimu ukuze kunamathele kangcono. Kodwa-ke, ukwelashwa ngokweqile kungaba nomphumela ophambene.

Ukwelashwa ngokweqile kungabangela:

Ukuqhekeka kwe-polymer chain kanye nokwakheka kwezingqimba zomngcele ezibuthakathaka.

Ukushiswa ngokweqile, okukhiqiza amakhemikhali anesisindo esincane sama-molecule.

Izimbobo ezincane kakhulu ezibeka engcupheni ubuqotho besivalo.

Isincomo sochwepheshe: Kumafilimu asekelwe ku-PE, gcina ububanzi be-corona buphakathi kwama-dynes angu-38–42/cm ukuze kufezwe ukusebenza okuzinzile ngaphandle kokuwohloka kobuso.

4. Amapharamitha Okuvala Angalingani — “Unxantathu Wegolide” Wokushisa, Ukucindezela, Nesikhathi

Ukuvala ukushisa empeleni kuyinqubo yokuncibilikisa nokubopha kabusha amaketanga e-thermoplastic ngaphansi kwezimo ezilawulwayo.

Uma izinga lokushisa, ingcindezi, kanye nesikhathi sokuhlala kungalingani kahle, ngisho namafilimu asezingeni eliphezulu ngeke avale kahle.

Isixazululo Sesayensi:

Yakha isizindalwazi sepharamitha yebanga ngalinye lefilimu, qinisekisa njalo ukuvala amafasitela, bese usebenzisa ukulandelela amarekhodi edijithali ukuqinisekisa ukuthi inqubo iyaphindaphindeka.

II. Izixazululo Eziqinisekisiwe ze-SILIKE Zokuqina Kwesivalo Sokushisa Okuthembekile

Ngeminyaka eminingi yocwaningo olusetshenziswa ezintweni zokupakisha, i-SILIKE inikeza izixazululo ezihlanganisiwe zokusiza abakhiqizi bamafilimu ukunqoba ukwehluleka kokuvala - kusukela ekusungulweni kwezinto ezibonakalayo kuya ekuthuthukisweni kwezinqubo.

OkwethuI-SILIMER Series Super Slip Masterbatchimele isizukulwane esisha seizithasiselo zokushelela ezingafuduki kanye nezithasiselo ezilwa nokuvimba, eyenzelwe ukuqeda ukuqhakaza komhlaba kanye nokuna kwempuphu ngenkathi igcina ukusebenza kahle kwefilimu. Ihlinzeka ngokuvala ukushisa okuqhubekayo, izakhiwo ezingafuduki, kanye nokuqeda ubuso okuhle kakhulu ekusetshenzisweni kwezikhwama zepulasitiki.

Izinzuzo Eziyinhloko zeIzithasiselo ze-SILIMER Series Super Slip kanye ne-Anti-Blocking

• Kuqeda Izinkinga Zempuphu

Kuvimbela ukufuduka kwe-ejenti eshelelayo futhi kuxazulula ngokuphelele inkinga evamile yokuna kwempuphu emhlophe ebusweni befilimu.

•Ukusebenza Okushelelayo Okuhlala Njalo

Igcina i-coefficient ezinzile nephansi yokungqubuzana kuyo yonke impilo yefilimu.

•Ukuvimbela Okuphezulu Okuphezulu

Kuthuthukisa ukusebenza kahle kokuphathwa kwefilimu futhi kuvimbela izendlalelo ukuthi zinganamatheli ndawonye ngesikhathi sokusonga noma sokugcina.

•Ubuhle Bomphezulu Obuthuthukisiwe

Inikeza indawo ebushelelezi, efanayo ukuze ibukeke kahle futhi ikhwalithi yokuthinta ibe ngcono.

•Akukho Ukuyekethisa Ezimpahleni Zamafilimu

Iqinisekisa ukuthi ukuphrinta okuhle kakhulu, ukuvala ukushisa, ukubopha, ukucaca, kanye nokusebenza komswakama akuthinteki.

•Kuphephile Futhi Akunaphunga

Kuhambisana nezindinganiso zomhlaba wonke zokuxhumana kokudla kanye nokupakisha imithi.

Izicelo Ezihlukahlukene

Izithasiselo zefilimu ezisebenzayo ze-SILIKE's SILIMER Series ziyahambisana nezinhlobo eziningi zama-polymer nezinhlobo zefilimu, okuhlanganisa:

•Amafilimu e-BOPP, CPP, PE, kanye ne-PP

•Amafilimu okupakisha aguquguqukayo, izikhwama zepulasitiki, namashidi okuvikela

•Imikhiqizo ye-polymer edinga izakhiwo ezithuthukisiwe zokushelela, zokulwa nokuvinjelwa, kanye nobuso

Lokhuukungabi nemvulaizithasiselo zokushelela nezokuvimbelaqinisekisa ukusebenza kahle kokuvala, ukucutshungulwa okuthuthukisiwe, kanye nokuqina kobuso besikhathi eside — isihluthulelo sokukhiqiza amafilimu okupakisha asezingeni eliphezulu nathembekile.

Ingabe ubhekene nezinkinga ezifana nokungahambisani kwe-heat seal, ukufuduka kwe-slip agent, noma i-white powder precipitation kumafilimu ahlanganisiwe?

I-SILIKE isiza abakhiqizi bokupakisha ukuqeda lezi zinselele ngokusebenzisa izinto ezintsha eziqhutshwa yisayensi. Uchungechunge lwethu lwe-SILIMER lusiza abakhiqizi bokupakisha ukuqeda lezi zinselele ngokusebenzisa ubuchwepheshe obusha.OkusebenzayoIzithasiselo ze-Slip ezingafuduki kanye ne-Anti-Blockinikeza ukusebenza okuhlala isikhathi eside kokushelela, ukuvala ukushisa okuzinzile, kanye nekhwalithi ephezulu yendawo — ngaphandle kokubeka engcupheni ukucaca, ukuphrinta, noma ukuphepha kokudla.

Visit www.siliketech.com to explore SILIKE’s full range of functional plastic film additives and efficient non-migrating hot slip agents. You can also contact our technical team at amy.wang@silike.cn ukuze uthole izincomo ezenzelwe wena mayelana nezithasiselo zokupakisha eziguquguqukayo.

I-SILIKE — umenzi wakho wezithasiselo othembekile wezixazululo ezintsha zokushelela kanye nezokulwa nokuvimba ezinhlelweni zokupakisha eziguquguqukayo.

Isikhathi sokuthunyelwe: Okthoba-19-2025