Inayiloni ecacile (njenge-PA6, i-PA66, i-PA12, kanye nama-copolyamides) isetshenziswa kakhulu ekusetshenzisweni kwezintambo nezintambo lapho kudingeka khona amandla omshini, ukumelana nokushisa, ukuphepha kukagesi, kanye nokuhlolwa okubonakalayo. Izibonelo ezijwayelekile zifaka phakathi amajakethi ekhebula e-THHN, THHWN, BVN, kanye ne-BVNVB noma izendlalelo zokufaka umswakama.

Kodwa-ke, ama-compound amaningi athola ukuthi uma ukucaca sekuqalisiwe, ukuzinza kokucubungula kwehla kakhulu.

Kungani Inayiloni Ebonakalayo Ilahlekelwa Ukugeleza kanye Nekhwalithi Yomphezulu Ngesikhathi Sokukhishwa Kwekhebula?

Emigqeni yokukhiqiza yangempela, ama-compounds ekhebula le-nylon abonakalayo avame ukuhlushwa yilokhu:

• Ukucindezela okuphezulu kokukhipha kanye nesivinini somugqa esingazinzile

• Ukugeleza kokuncibilika okubi, ikakhulukazi lapho kugcwaliswa kakhulu noma kufakwe umbala

• Ukungalungi kobuso, imigqa yokusika, noma imihuzuko emincane

• Ukulahlekelwa kokubonakala okubangelwa ukucindezeleka kokushisa noma ukucindezeleka kokusika

• Ukuqongelela kwama-die kanye nezidingo zokuhlanza njalo

Lezi zinkinga zithinta ngqo umkhiqizo, ukuqina kokubukeka, kanye nokuthembeka kwekhebula.

Izinselele Zangempela Zokucubungula Ezingemuva Kwe-PA6 / PA12 Ebonakalayo

Ngokungafani nezinhlelo ze-nylon ezingacacile, i-nylon ecacile incike ekubunjweni kwamakristalu okulawulwayo noma ukwakheka kwama-molecule angenasimo. Nakuba lokhu kwenza kube nokwenzeka ukucaca kokukhanya, futhi kwethula ukuzwela kokucubungula:

• Izindawo ezi-semi-crystalline zisabela kakhulu ekusikeni nasekushiseni

• Amafasitela okucubungula amancane andisa ukuguquguquka kwe-viscosity

• Izinto zokugcoba ezivamile zingase zithuthe, ziqhakaze, noma zisakaze ukukhanya

• Ukungqubuzana kwangaphakathi kuyakhuphuka, okuholela ekuqineni okukhulu kanye nokucindezela

Ngenxa yalokho, izinsiza ezijwayelekile zokucubungula inayiloni zivame ukwehluleka ukuletha i-extrusion eqinile ngaphandle kokulahlekelwa ukucaca.

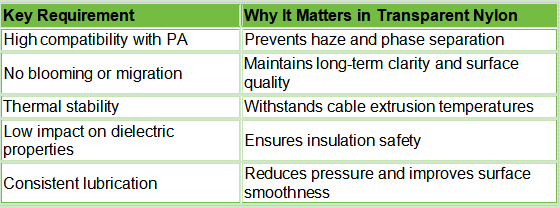

Yini Eyenza I-Lubricant Ifanelekele Ama-Compounds Ekhebula Le-Nylon Elibonakalayo?

Ekusetshenzisweni kwezintambo nezintambo, i-lubricant kumele ixazulule izinkinga zokucubungula ngaphandle kokuphazamisa ukusebenza kwe-optical noma kagesi.

Izithambisi ezihlulekayo kunoma iyiphi yalezi zindawo zingathuthukisa ukugeleza kwamanzi okwesikhashana kodwa zilethe amaphutha athile.

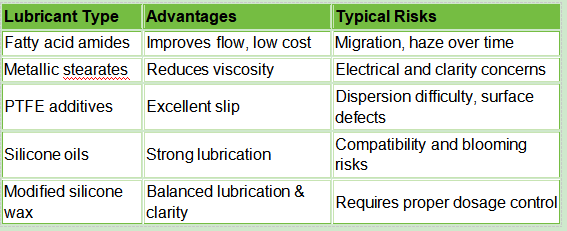

Ukuqhathaniswa Kwezinhlobo Zokugcoba Zokucubungula I-Nylon Ebonakalayo

Phakathi kwalezi zinketho,ama-wax e-silicone aguquliwezithandwa kakhulu ngama-compounds ekhebula le-nylon abonakalayo ngenxa yokuqina nokuhambisana kwazo.

Indlela I-Silicone Wax Eguquliwe Exazulula Ngayo Lezi Zinkinga Ngokusebenzayo

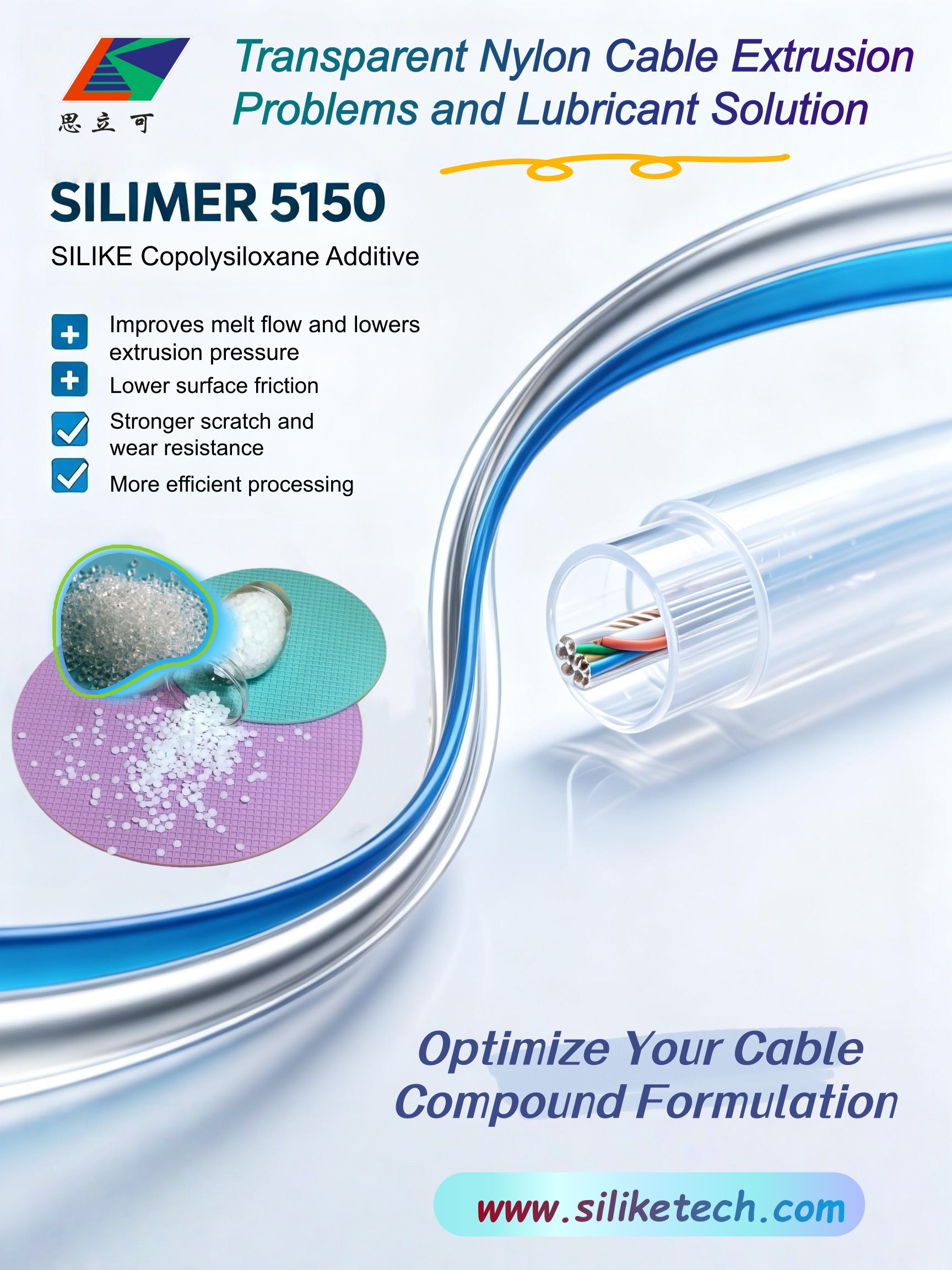

I-SILIKE SILIMER 5150 iyi-Isithasiselo kanye ne-Modifier ye-Copolysiloxane.Ama-silicone wax aguquliwe ngendlela esebenzayo aklanywe ngezakhiwo ze-copolymer ezisebenzisana ngendlela efanayo nama-nylon matrices. Lokhu kuwavumela ukuthi:

√Nciphisa ukungqubuzana kwangaphakathi nangaphandle ngasikhathi sinye

√Thuthukisa ukugeleza kokuncibilika kanye nokugcwaliswa kwesikhunta noma kokufa

√Nciphisa ukwakheka kwama-die ngesikhathi sokukhiqiza isikhathi eside

√Gcina ukucaca kanye nokucwebezela kobuso

√Thuthukisa ukumelana nokuklwebheka nokuklwebheka kwezintambo eziqediwe

I-SILIKE SILIMER 5150 ingenye yalezi zinhlobo ze-silicone wax eziguquliwe. Njengesengezo sokucubungula amafutha esisekelwe ku-silicone, yenzelwe ukuletha amafutha amaningi ngaphandle kwemvula, ukuqhakaza, noma ukulahleka kokukhanya. Kumakhemikhali ekhebula le-PA6, PA12, kanye ne-copolyamide abonakalayo, iyasiza ekuqiniseni i-extrusion ngenkathi igcina ukuqeda okubushelelezi nokucacile.

Kunini Lapho Kufanele Ucabangele I-Lubricant Ye-Silicone Wax Engeziwe Yokucubungula Njenge-SILIMER 5150?

Lolu hlobo lwesithasiselo sokucubungula amafutha lufaneleka kakhulu uma:

√Ukucaca okuphezulu kumele kugcinwe ngemuva kokukhipha

√Ingcindezi yokukhipha imingcele yesivinini somugqa

√Ukuklwebheka okungaphezulu noma imigqa yodayi kubangela izikhalazo zekhwalithi

√Imijikelezo emide yokukhiqiza yandisa ingozi yokuqongelela ukufa

√Kokubili ukuqina kwemishini kanye nokubukeka kubalulekile

Kulezi zinhlelo zokusebenza, izithasiselo ze-silicone wax eziguquliwe zinikeza ibhalansi esebenzayo phakathi kokusebenza kahle kokucubungula kanye nokusebenza kwekhebula kokugcina.

Imibuzo Evame Ukubuzwa Mayelana Nokugcoba Kwezintambo Zenayiloni Ezibonakalayo

Ingabei-silicone waxkuthinta ukusebenza kokuvikela ugesi?

Uma zenziwe kahle, ama-silicone wax aguquliwe awathinti kakhulu izakhiwo ze-dielectric futhi asetshenziswa kabanzi ezinhlelweni zokuvikela izintambo.

Intandoizithasiselo ze-waxukunciphisa ukucaca?

Ukuhambisana kubalulekile. Ama-wax e-silicone aguquliwe aklanyelwe ama-polyamides agcina ukucaca kangcono kune-wax evamile noma amafutha okuthutha.

Iyini imithamo ejwayelekile yokulinganisaIsengezo se-Copolysiloxane kanye ne-Modifier SILIMER 5150?

Iningi lamakhemikhali e-nylon abonakalayo asebenzisa u-0.5–1.0 wt%, kuye ngohlobo lwe-resin kanye nezimo zokucubungula.

Ufuna isiqondiso sokwakheka noma usizo lwesampula yokugcoba ukuze uthuthukise ukugeleza kokuncibilika futhi wandise ubushelefu kuma-compounds ekhebula le-nylon abonakalayo?

Kungakhathaliseki ukuthi isetshenziswa ekubunjweni komjovo noma ekukhipheni, i-SILIKE Copolysiloxane Additive kanye ne-Modifier SILIMER 5150 inegalelo ekunciphiseni amaphutha okucubungula, inciphisa ukufakwa kwe-die, futhi ithuthukisa ukumelana nokuklwebheka nokuklwebheka. Ngenxa yalokho, ivela njengokukhetha okuhle kakhulu kwezinhlelo zokusebenza ezisekelwe kwi-nylon ezidinga ukuqina, ukuqeda okubushelelezi, kanye nokubonakala okuphezulu.

Xhumana nethimba lobuchwepheshe le-SILIKE ukuze uthole izincomo ezifanele mayelana ne-silicone wax eguquliwe ekucutshungulweni kwe-polyamide (PA) kanye nokuthuthukiswa kwezakhiwo zomphezulu (ukuthamba, ukushelela, i-friction coefficient ephansi, ukuthungwa okusilika), kanye nesampula yezithasiselo ezisekelwe ku-silicone ze-surface finish enhancer yezinto ze-nylon.

Tel: +86- 28 – 83625089 or Email: amy.wang@silike.cn. Website: www.siliketech.com.

Isikhathi sokuthunyelwe: Jan-21-2026