Isixazululo se-Si-TPV sendwangu ethambile eboshwe nge-laminate noma indwangu ene-clip mesh enokumelana namabala

Isixazululo se-Si-TPV sendwangu ethambile eboshwe nge-laminate noma indwangu ene-clip mesh ekwazi ukumelana namabala,

indwangu ye-clip mesh, indwangu ehlanganisiwe, Ifilimu ye-Si-TPV, I-TPU, Izinto ezihlanganisiwe zefilimu ye-TPU, Indwangu eboshwe nge-TPU,

INCAZELO

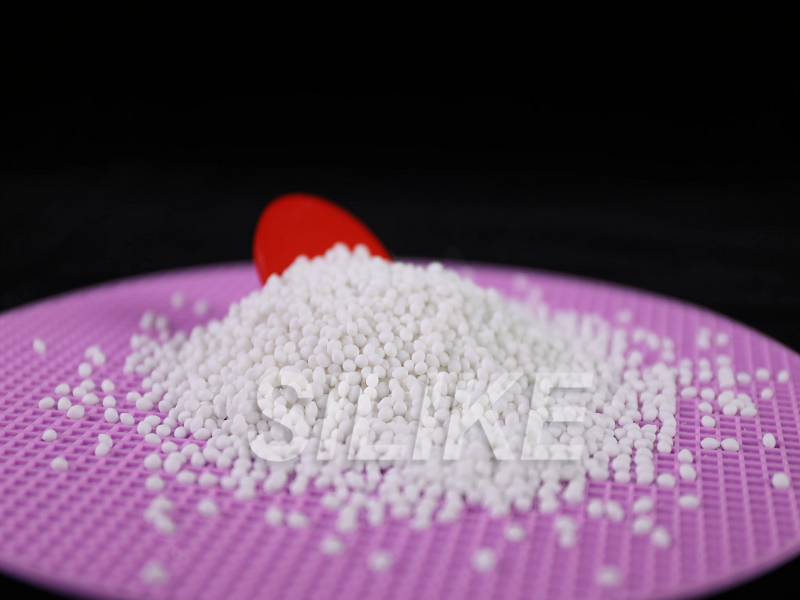

I-SILIKE Si-TPV® thermoplastic elastomer iyi-elastomer esuselwe ku-silicone eguquguqukayo evulcanized thermoplastic eyenziwe ngobuchwepheshe obukhethekile obuhambisanayo ukusiza irabha ye-silicone ehlakazeke ku-TPU ngokulinganayo njengezinhlayiya ze-micron ezingu-2 ~ 3 ngaphansi kwe-microscope. Lezo zinto eziyingqayizivele zihlanganisa amandla, ukuqina kanye nokumelana nokuguguleka kwanoma iyiphi i-thermoplastic elastomer nezakhiwo ezifiselekayo ze-silicone: ubumnene, umuzwa wesilika, ukukhanya kwe-UV kanye nokumelana namakhemikhali okungaphinde kusetshenziswe futhi kusetshenziswe kabusha ezinqubweni zokukhiqiza zendabuko.

I-Si-TPV® 3520-70A thermoplastic elastomer iyinto enokuguguleka okuhle kanye nomuzwa othambile wesilika ongaxhuma kahle ne-PC, i-ABS, i-TPU kanye nezinye izinto ezifanayo ze-polar. Ingumkhiqizo owenzelwe ukubumba okuthambile kokuthinta kuma-elekthronikhi agqokwayo, amakesi okwengeza amadivayisi kagesi, amabhande ewashi.

IZICELO

Isixazululo sokubumba okuthambile kuma-smart phone, emakesini e-elekthronikhi aphathwayo, ibhande lesihlakala le-smartwatch, amabhande, namanye amadivayisi e-elekthronikhi agqokwayo.

IZINDAWO EZIJWAYELEKILE

| Isivivinyo* | Impahla | Iyunithi | Umphumela |

| I-ISO 868 | Ukuqina (imizuzwana eyi-15) | Ugu A | 71 |

| I-ISO 1183 | Amandla adonsela phansi athile | – | 1.11 |

| I-ISO 1133 | Inkomba Yokugeleza Kokuncibilika 10 kg kanye no-190°C | g/10 iminithi | 48 |

| I-ISO 37 | I-MOE (i-Modulus yokunwebeka) | I-MPa | 6.4 |

| I-ISO 37 | Amandla Okudonsa | I-MPa | 18 |

| I-ISO 37 | Ukucindezeleka Okuqinile @ 100% Ukwandiswa | I-MPa | 2.9 |

| I-ISO 37 | Ukwelula ngesikhathi sokuphumula | % | 821 |

| I-ISO 34 | Amandla Okudabuka | kN/m | 55 |

| I-ISO 815 | Isethi Yokucindezela Amahora angu-22 @ 23°C | % | 29 |

*ISO: Inhlangano Yomhlaba Wonke Yokulinganisa I-ASTM: I-American Society for Testing and Materials

IZICI NEZINZUZO

(1) Ukuzizwa okuthambile okufana nosilika

(2) Ukumelana okuhle nokuklwebheka

(3) Ukubopha okuhle kakhulu kwi-PC, i-ABS

(4) Ukungathandi amanzi kakhulu

(5) Ukumelana namabala

(6) Ukuqina kwe-UV

ISETSHENZISWA KANJANI

• Umhlahlandlela Wokucubungula Ukubumba Ngomjovo

| Isikhathi Sokomisa | Amahora angu-2–6 |

| Izinga Lokushisa Lokomisa | 80–100°C |

| Izinga Lokushisa Lendawo Yokuphakelayo | 150–180°C |

| Izinga Lokushisa Lendawo Ephakathi | 170–190°C |

| Izinga Lokushisa Lendawo Engaphambili | 180–200°C |

| Izinga lokushisa le-Nozzle | 180–200°C |

| Izinga Lokushisa Elincibilikayo | 200°C |

| Izinga Lokushisa Lesikhunta | 20–40°C |

| Isivinini Somjovo | I-Medical |

Lezi zimo zenqubo zingahluka ngokwemishini nezinqubo ngazinye.

• OkwesibiliUkucubungula

Njengezinto ze-thermoplastic, izinto ze-Si-TPV® zingacutshungulwa ngokwesibili ngemikhiqizo evamile

•UmjovoUkubumbaIngcindezi

Ingcindezi yokubamba incike kakhulu ku-geometry, ukujiya kanye nendawo yesango lomkhiqizo. Ingcindezi yokubamba kufanele isethwe ibe nenani eliphansi ekuqaleni, bese ikhuphuka kancane kancane kuze kube yilapho kungekho ziphambeko ezihlobene ezibonakala kumkhiqizo obunjwe ngomjovo. Ngenxa yezakhiwo zokunwebeka zezinto, ingcindezi yokubamba ngokweqile ingabangela ukuwohloka okukhulu kwengxenye yesango lomkhiqizo.

• Ukucindezeleka komhlane

Kunconywa ukuthi ingcindezi yangemuva lapho isikulufu sihoxiswa kufanele ibe ngu-0.7-1.4Mpa, okungeke nje kuqinisekise ukufana kokuncibilika kokuncibilika, kodwa futhi kuqinisekise ukuthi izinto aziboli kakhulu ngokucheba. Isivinini sesikulufu esinconywayo se-Si-TPV® singu-100-150rpm ukuqinisekisa ukuncibilika okuphelele kanye nokufakwa kwepulasitiki kwezinto ngaphandle kokuwohloka kwezinto okubangelwa ukushisa kwe-shear.

UKUPHATHA IZINYATHELO ZOKWEQAPHELA

Kunconywa umshini wokomisa osusa umswakama we-desiccant kuzo zonke izinhlobo zokomisa.

Ulwazi lokuphepha komkhiqizo oludingekayo ukuze kusetshenziswe ngokuphephile alufakiwe kulo mbhalo. Ngaphambi kokuphatha, funda amaphepha edatha yomkhiqizo nokuphepha kanye namalebula ezitsha ukuze kusetshenziswe ngokuphephile, ulwazi oluyingozi ngokomzimba nangokwempilo. Ishidi ledatha lokuphepha liyatholakala kuwebhusayithi yenkampani i-silike ku-siliketech.com, noma kumsabalalisi, noma ngokufonela isevisi yamakhasimende i-Silike.

UKUPHILA NOKUGCINA OKUSEBENZISEKAYO

Thutha njengamakhemikhali angewona ingozi. Gcina endaweni epholile, enomoya omuhle. Izici zokuqala zihlala zinjalo izinyanga ezingama-24 kusukela ngosuku lokukhiqiza, uma zigcinwe endaweni yokugcina enconyiwe.

ULWAZI LOKUPHAKISHA

25KG/isikhwama, isikhwama sephepha esenziwe ngezandla esinesikhwama sangaphakathi se-PE.

IMIKHAWULO

Lo mkhiqizo awuhlolwanga futhi awuvezwa njengofanele ukusetshenziswa kwezokwelapha noma kwemithi.

ULWAZI LWESIQINISEKISO OLUNEMIQATHANGO – SICELA UFUNDE NGOKUQAPHELA

Ulwazi oluqukethwe lapha lunikezwa ngokwethembeka futhi kukholakala ukuthi lunembile. Kodwa-ke, ngenxa yokuthi izimo nezindlela zokusebenzisa imikhiqizo yethu zingaphezu kwamandla ethu, lolu lwazi akufanele lusetshenziswe esikhundleni sokuhlolwa kwamakhasimende ukuqinisekisa ukuthi imikhiqizo yethu iphephile, isebenza kahle, futhi iyanelisa ngokugcwele ukusetshenziswa okuhlosiwe. Iziphakamiso zokusebenzisa akufanele zithathwe njengezisusa zokwephula noma yiliphi ilungelo lobunikazi.

Indwangu elaminethiwe ye-TPU isebenzisa ifilimu ye-TPU ukuhlanganisa izindwangu ezahlukahlukene ukuze yakhe izinto ezihlanganisiwe, ubuso bendwangu elaminethiwe ye-TPU bunemisebenzi ekhethekile njengokungangeni manzi kanye nokumunca umswakama, ukumelana nemisebe, ukumelana nokuguguleka, okungagezwa ngomshini wokuwasha, ukumelana nokuguguleka, kanye nokumelana nomoya. Ngakho-ke, i-TPU ibhekwa njengesinqumo esifanele sendwangu elaminethiwe noma indwangu ene-clip mesh.

Kodwa-ke, kunezinkinga enqubweni yokukhiqizwa kwendwangu eboshwe nge-TPU, iningi labo lithenga ifilimu ye-TPU ezimbonini zamafilimu zangaphandle futhi liqeda inqubo yokunamathisela nokunamathisela. Enqubweni yokunamathisela ngemva kokunamathisela, izinga lokushisa eliphezulu kanye nokucindezela okuphezulu kufakwa efilimini ye-TPU futhi. Ukulawulwa kwenqubo okungalungile kuzobangela umonakalo efilimini ngisho nasezimbobeni ezincane.

Ama-elastomer asekelwe ku-Silicone (i-Si-TPV) e-SILIKE Dynamic vulcanizate thermoplastic ahlinzeka ngesisombululo esisha esifanelekile sendwangu eboshwe nge-laminate noma indwangu ene-clip-mesh.

IZITHASISELO ZAMAHHALA ZE-SILICONE NAMASAMPULA E-SI-TPV AMABANGA ANGAPHEZU KWE-100

Uhlobo lwesampula

$0

- 50+

amamaki e-Silicone Masterbatch

- 10+

amamaki e-Silicone Powder

- 10+

amamaki e-Anti-scratch Masterbatch

- 10+

amamaki Anti-abrasion Masterbatch

- 10+

amamaki e-Si-TPV

- 8+

amamaki e-Silicone Wax

-

Ucingo

-

I-imeyili

-

I-Whatsapp

I-Whatsapp

-

Phezulu

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-300x199.jpg)