Yisiphi isithasiselo sokulwa nokuguguleka esenza amathe ezicathulo amelane nokuguguleka?

Yisiphi isithasiselo esilwa nokuguguleka esenza amathe ezicathulo amelane nokuguguleka?,

ukumelana nokuklwebheka, isithasiselo sokulwa nokugqokwa, izithende zezicathulo, Izithasiselo ze-Silicone,

Incazelo

I-masterbatch yokulwa nokuguguleka (i-anti-wear agent) i-NM-2T iyifomula eyenziwe nge-pelletized ene-polymer engu-50% ye-UHMW Siloxane esakazeke ku-resin ye-EVA. Iyinguqulo ethuthukisiwe ye-masterbatch yethu yangaphambili ye-Anti-abrasion NM-2 ene-Siloxane esezingeni elingcono kanye nokuqukethwe okuphezulu kwe-siloxane. Yakhelwe ngokukhethekile uhlelo lwe-resin oluhambisana ne-EVA noma i-EVA ukuze kuthuthukiswe ukumelana nokuguguleka kwezinto zokugcina kanye nokunciphisa inani lokuguguleka kuma-thermoplastics.

Uma kuqhathaniswa nezithasiselo ze-Silicone / Siloxane ezivamile ezinesisindo esiphansi sama-molecule, njenge-Silicone oil, i-silicone fluids noma ezinye izinhlobo zezithasiselo zokuguguleka, i-SILIKE Anti-abrasion Masterbatch NM-2T kulindeleke ukuthi inikeze isici esingcono kakhulu sokumelana nokuguguleka ngaphandle kwethonya ebulukhunini nombala.

Amapharamitha Ayisisekelo

| Igama | I-NM-2T |

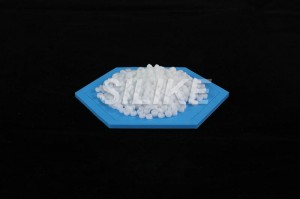

| Ukubukeka | I-pellet emhlophe |

| Okuqukethwe kwezithako ezisebenzayo % | 50 |

| Isisekelo se-resin | I-EVA |

| Isilinganiso % | 0.5~5% |

| Izicelo | I-EVA, i-PVC sole |

Izinzuzo

(1) Ukumelana nokuklwebheka okuthuthukisiwe kanye nenani lokuklwebheka elinciphile

(2) Nikeza ukusebenza kokucubungula kanye nokubukeka kwezinto zokugcina

(3) Ivikela imvelo

(4) Akukho thonya ebulukhunini nombala

(5) Isebenza kahle ekuhlolweni kwe-DIN, ASTM, NBS, AKRON, SATRA, GB abrasion

Izicelo

(1) Izicathulo ze-EVA

(2) Izicathulo ze-PVC

(3) Ama-compound e-EVA

(4) Amanye amapulasitiki ahambisana ne-EVA

Isetshenziswa kanjani

I-SILIKE Anti-abrasion masterbatch ingacutshungulwa ngendlela efanayo nesithwali se-resin abasekelwe kuso. Ingasetshenziswa enkambisweni yokuxuba yokuncibilika yakudala njenge-Single / Twin screw extruder, i-injection molding. Kunconywa ukuxuba okungokoqobo nama-pellet e-polymer ahlanzekile.

Ncoma umthamo

Uma kufakwe ku-EVA noma ku-thermoplastic efanayo ku-0.2 kuya ku-1%, ukucubungula nokugeleza kwe-resin okuthuthukisiwe kulindeleke, kufaka phakathi ukugcwaliswa okungcono kwesikhunta, i-torque encane ye-extruder, amafutha angaphakathi, ukukhululwa kwesikhunta kanye nokusetshenziswa okusheshayo; Ezingeni eliphezulu lokwengeza, 2 ~ 10%, kulindeleke izakhiwo ezithuthukisiwe zomphezulu, kufaka phakathi ukuthambisa, ukushelela, i-coefficient ephansi yokungqubuzana kanye nokumelana okukhulu kwe-mar/scratch kanye nokuklwebheka.

Iphakheji

25Kg/isikhwama, isikhwama sephepha lezandla

Isitoreji

Thutha njengamakhemikhali angewona ingozi. Gcina endaweni epholile, enomoya omuhle.

Isikhathi sokuphelelwa yisikhathi

Izici zokuqala zihlala zinjalo izinyanga ezingama-24 kusukela ngosuku lokukhiqiza, uma zigcinwe endaweni yokugcina enconyiwe.

I-Chengdu Silike Technology Co., Ltd ingumkhiqizi kanye nomhlinzeki wezinto ze-silicone, ezinikele ku-R&D yokuhlanganiswa kwe-Silicone ne-thermoplastics iminyaka engama-20.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnSilicone additives are used to make shoe soles more abrasion resistant because they create a protective layer on the surface of the sole. This layer helps to reduce the amount of wear and tear that the sole experiences, making it more durable and longer lasting. Silicone additives also help to reduce the amount of friction between the sole and the ground, which can help to reduce the amount of wear and tear that the sole experiences.

IZITHASISELO ZAMAHHALA ZE-SILICONE NAMASAMPULA E-SI-TPV AMABANGA ANGAPHEZU KWE-100

Uhlobo lwesampula

$0

- 50+

amamaki e-Silicone Masterbatch

- 10+

amamaki e-Silicone Powder

- 10+

amamaki e-Anti-scratch Masterbatch

- 10+

amamaki Anti-abrasion Masterbatch

- 10+

amamaki e-Si-TPV

- 8+

amamaki e-Silicone Wax

-

Ucingo

-

I-imeyili

-

I-Whatsapp

I-Whatsapp

-

Phezulu

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur