Isiliphu se-SILIMER esingenamvula kanye ne-masterbatch yokulwa nokuvimba ifilimu yokupakisha ukudla

Impuphu emhlophe ethela esikhwameni sokupakisha ukudla ingenxa yokuthi i-slip agent (i-oleic acid amide, i-erucic acid amide) esetshenziswa umenzi wefilimu ngokwayo iyathela, futhi indlela esebenza ngayo i-amide slip agent yendabuko ukuthi isithako esisebenzayo sithuthela ebusweni befilimu, sakhe ungqimba olulodwa lokugcoba lwama-molecule futhi sinciphise i-friction coefficient yobuso befilimu. Kodwa-ke, ngenxa yesisindo esincane sama-molecule se-amide slip agent, kulula ukuyithela noma ukuyithela, ngakho-ke impuphu kulula ukuyihlala ku-composite roller ngesikhathi senqubo yokuhlanganisa ifilimu, futhi impuphu ku-raber roller izonamathela ngesikhathi sokucubungula ifilimu, okuholela ku-white powder esobala kumkhiqizo wokugcina.

Ukuze kuxazululwe inkinga yokunisela kalula kwe-amide slip agent yendabuko, i-SILIKE ithuthukise umkhiqizo we-co-polysiloxane oguquliwe oqukethe amaqembu asebenzayo asebenzayo e-organic -I-masterbatch yefilimu yokushelela engangenisi imvula yochungechunge lwe-silimer. Isimiso sokusebenza salo mkhiqizo sithi: Uchungechunge olude lwekhabhoni kanye ne-resin kuyahambisana nokudlala indima yokubambelela, futhi uchungechunge lwe-silicone luyahamba luye ebusweni befilimu ukuze ludlale indima yokushelela, ukuze ludlale indima yokushelela ngaphandle kwemvula ngokuphelele. Amabanga anconyiwe:SILIMER5064, I-SILIMER5064MB1, I-SILIMER5064MB2, I-SILIMER5065HB...

•Izinzuzo ezijwayelekile zomkhiqizo

•Ukumelana okuhle nokushisa okuphezulu

•Ukusebenza okubushelelezi okuhlala isikhathi eside

•Kuphephile futhi akunaphunga

•Akuthinte ukuphrinta amafilimu, ukuhlanganiswa, nokucaca

•Kusetshenziswa kabanzi kumafilimu e-BOPP/CPP/PE/PP......

•Idatha ethile yokuhlola ukusebenza efanele

Kunciphisa ngempumelelo i-coefficient yokungqubuzana, akuthinti izinga lenkungu kanye nokudluliselwa kwayo

Ifomula ye-substrate elingisiwe: 70%LLDPE, 20%LDPE, 10% metallocene PE

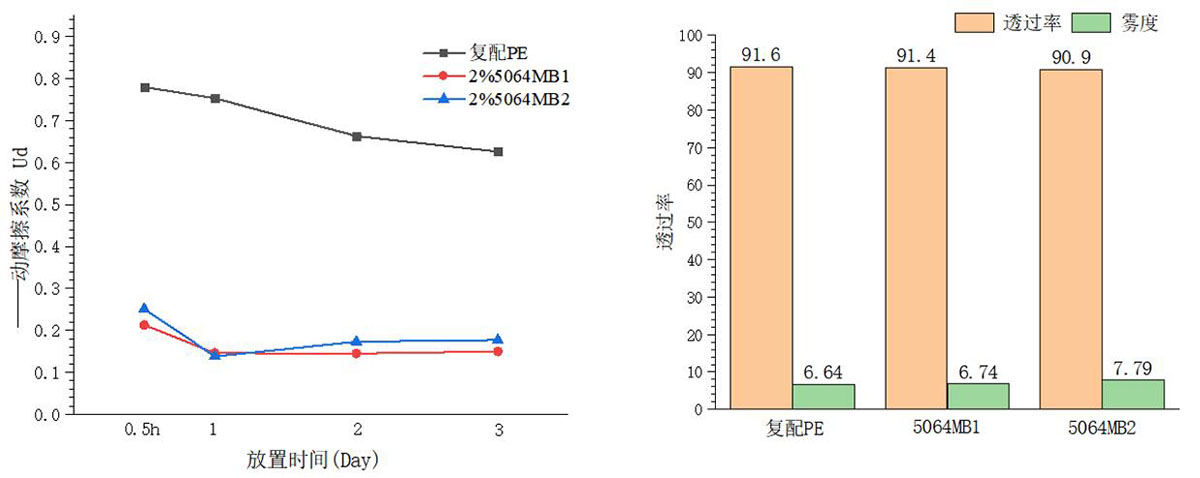

Njengoba kuboniswe kuMfanekiso 1, i-coefficient yokungqubuzana kwefilimu ngemva kokwengeza u-2% SILIMER 5064MB1 kanye no-2% SILIMER 5064MB2 yehliswe kakhulu uma kuqhathaniswa ne-composite PE. Ngaphezu kwalokho, futhi njengoba kuboniswe kuMfanekiso 2, ukwengezwa kwe-SILIMER 5064MB1 kanye ne-SILIMER 5064MB2 akuzange kuthinte izinga lenkungu kanye nokudluliselwa kwefilimu.

•I-coefficient yokungqubuzana izinzile

Izimo zokupholisa: izinga lokushisa 45℃, umswakama 85%, isikhathi 12h, izikhathi ezi-4

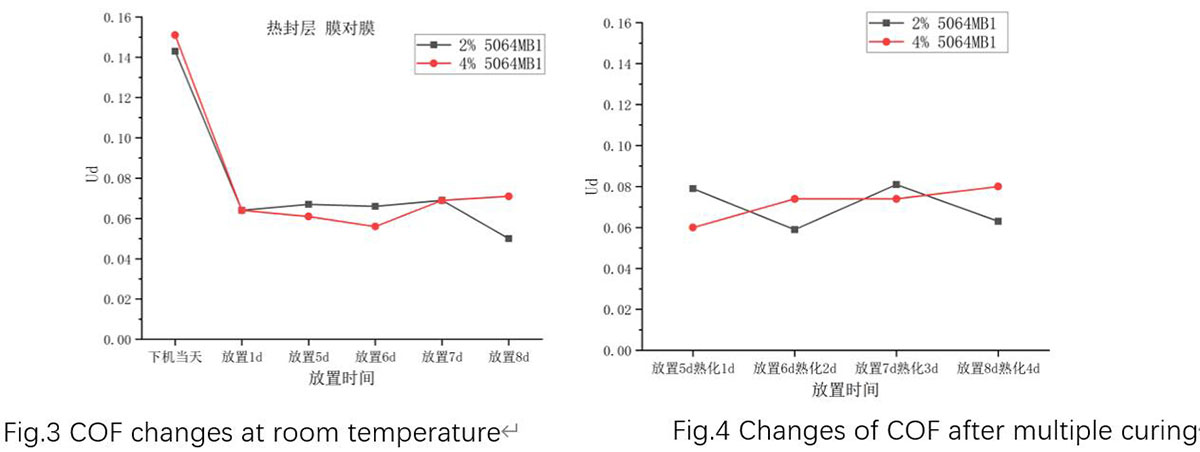

Njengoba kuboniswe ku-FIG. 3 kanye no-FIG. 4, kungabonakala ukuthi i-coefficient yokungqubuzana kwefilimu ngemva kokwengeza u-2% SILIMER 5064MB1 kanye no-4% SILIMER 5064MB1 ihlala inenani elizinzile ngemva kokulungiswa kaningi.

• Ubuso befilimu abunamanzi futhi abuthinti ikhwalithi yemishini kanye nomkhiqizo wokugcina

Njengoba kuboniswe esithombeni esingezansi, sebenzisa indwangu emnyama ukusula ubuso befilimu ngomkhiqizo we-amide kanye ne-SILIMER. Kungabonakala ukuthi uma kuqhathaniswa nokusetshenziswa kwezithasiselo ze-amide,Uchungechunge lwe-SILIMERayivuthisi futhi ayinayo i-powder evuthelayo.

•Xazulula inkinga yempuphu emhlophe ku-composite roller kanye nesikhwama sokugcina somkhiqizo

Njengoba kuboniswe esithombeni esingezansi, ngemva kokuba i-composite roller idlule amamitha angu-6000 efilimu ene-erucic acid amide, kuba nokuqongelela okusobala kwempuphu emhlophe, futhi kukhona nempuphu emhlophe esobala esikhwameni somkhiqizo wokugcina; Kodwa-ke, isetshenziswa neUchungechunge lwe-SILIMERSingabona ukuthi i-composite roller idlule nini amamitha angu-21000, futhi isikhwama sokugcina somkhiqizo sasihlanzekile futhi sisha.

Ukwengeza i-amide

Ukungeza uchungechunge lwe-Silimer

i-masterbatch yefilimu engenamvula ye-SILIMER, gcina umnyango wokuqala wokuphepha kokudla, qinisekisa ukuphepha komthwalo wemfanelo wokupakisha ukudla! Uma uhlangabezana nanoma yimiphi imibuzo mayelana nezikhwama zokupakisha ukudla noma amanye amafilimu, sicela uxhumane nathi, sizojabula ukwenza ngezifiso izixazululo zakho!